17

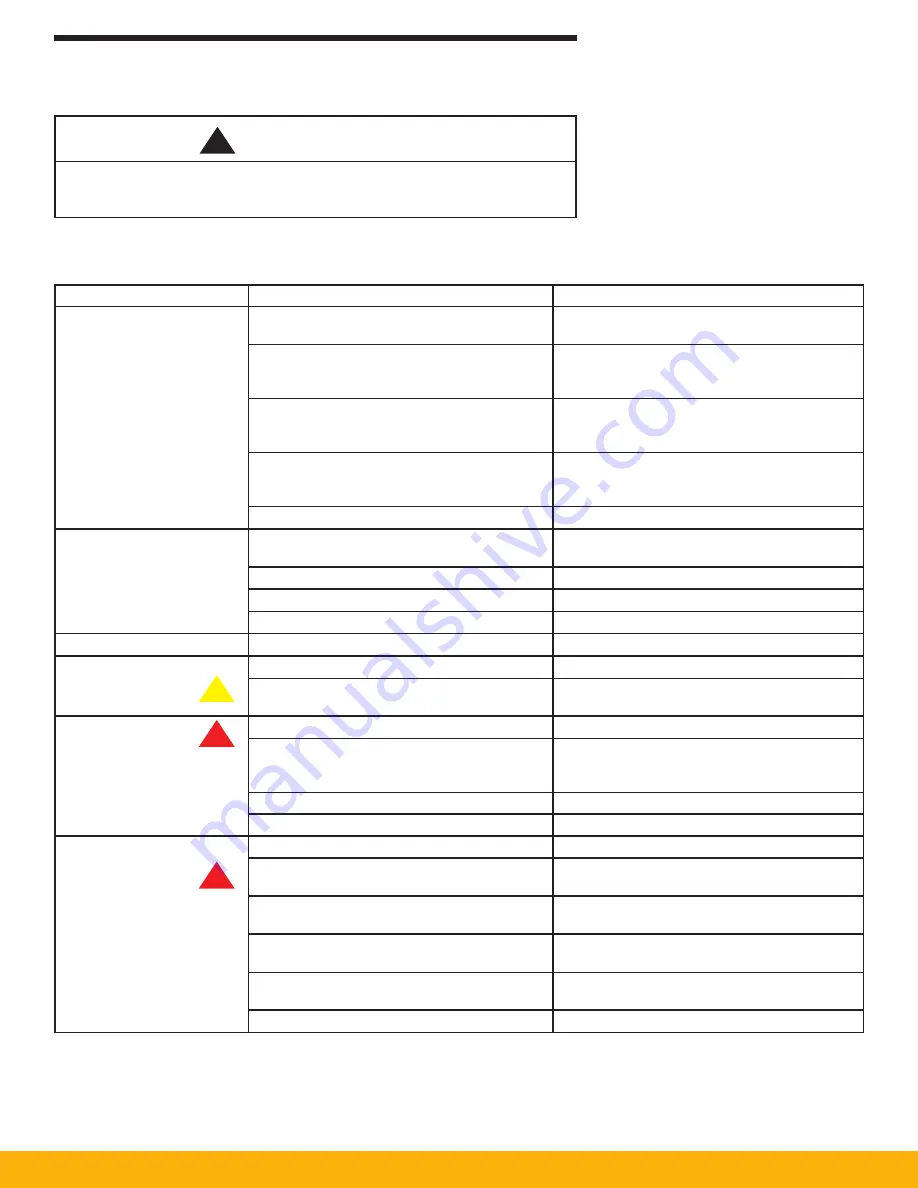

6. Troubleshooting Guide

Use the troubleshooting guide to correct any problems that occur with your oil mist col-

lection unit. If the problem or condition continues, contact the Parker customer service.

All electrical/mechanical troubleshooting should be performed by a quali-

fied electrician/maintenance individual familiar with Parker equipment.

Prior to troubleshooting any equipment, read the Installation and Operation Manuals for

each piece of equipment to be serviced.

!

WARNING

Problem

Possible Causes

Recommended Solutions

Lack of air flow

Restriction at the outlet of unit

Be sure there are no obstructions in close prox-

imity to the outlet at the top of the unit

Inaccurate dP readings, leading to possible

auto-flow malfunction

Check for misaligned filters, leaks in ducting,

leaks in plumbing, filter failure, or transducer and

connection failures

Blinded filters

Clean cartridge filters with a hose or other low

pressure water source

Replace filter(s)

Leaking gaskets

Check for damaged gaskets and replace if nec-

essary, careful adjustment of latch paws may be

necessary if leak persists

Restriction or blockage in inlet ducting

Verify all dampers are open, duct is unobstructed

System Off

Tripped circuit breaker

Open rear panel on unit and switch breaker if

necessary

Loose or disconnected wires

Investigate wiring in the rear panel

Disconnect is switched to OFF position

Switch disconnect to ON position

Improper source power

Refer to data plate to verify required input power

Screen Displayed Warning

Possible Causes

Recommended Solutions

Filter Caution (Yellow)

Filter is approaching max life

Replace filter(s) soon

Restriction in dP readings

Check for kinked tubing, obstructed pressure

taps

Filter Warning (Red)

Filter has surpassed max life

Replace filter(s)

Blinded filters

Clean cartridge filters with a hose or other low

pressure water source

Replace filter(s)

Pressure taps obstructed

Check and clear pressure taps in the unit

Pressure tubing is kinked or plugged

Check and clear all tubing in the unit

Blower Warning* (Red)

Improper source power

Refer to data plate to verify required input power

Phase loss

Check for loose/disconnected wires, shorts, or

tripped circuit breakers

Motor over-temp.

Shut system off (if not already) and allow motor

to cool. If issue repeats, contact a Parker rep.

Auto-flow set point cannot be reached

Verify auto-flow value is set properly, check

filter(s) for replacement

Total system static pressure exceeds blower

capability

Reduce static pressure in system

Refer to “Lack of air flow” section above

Other

Contact a Parker representative for assistance

!

!

!

*Always refer initially to the fault screen displayed on the unit

Содержание SmogHog SHM-C

Страница 1: ...SMOG HOG Media Mist Collector Owner s Manual Models SHM C SHM F...

Страница 6: ...Page intentionally left blank...

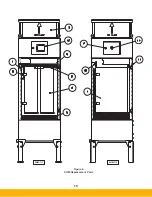

Страница 8: ...4 FIGURE 1B SHM Equipment Description 61 10113 FIGURE 1A SHM Equipment Description...

Страница 13: ...9 61 10126 FIGURE 4 Remote Panel Touchscreen Connection...

Страница 15: ...11 61 10115 FIGURE 5B SHM Filter Removal Installation FIGURE 5A SHM Filter Removal Installation...

Страница 23: ...19 Figure 6 SHM Replacement Parts SHM 11C SHM 11F...

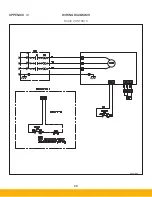

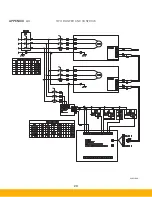

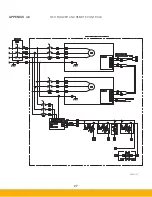

Страница 24: ...20 APPENDIX A1 WIRING DIAGRAMS BASIC CONTROLS 04 001682...

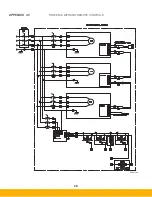

Страница 25: ...21 REMOTE PANEL BASIC CONTROLS 04 001799 APPENDIX A2...

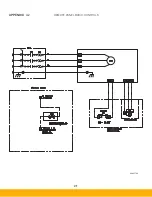

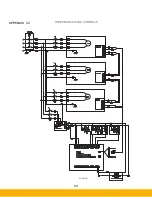

Страница 26: ...22 ONE BLOWER AND CONTROLS 04 001695 APPENDIX A3...

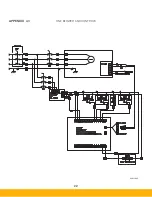

Страница 27: ...23 TWO BLOWER AND CONTROLS 04 001696 APPENDIX A4...

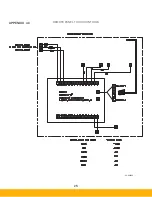

Страница 28: ...24 THREE BLOWER AND CONTROLS 04 001697 APPENDIX A5...

Страница 29: ...25 REMOTE PANEL TOUCH CONTROLS 04 001802 APPENDIX A6...

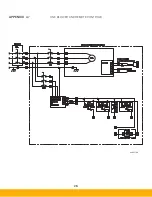

Страница 30: ...26 ONE BLOWER AND REMOTE CONTROLS 04 001798 APPENDIX A7...

Страница 31: ...27 TWO BLOWER AND REMOTE CONTROLS 04 001797 APPENDIX A8...

Страница 32: ...28 THREE BLOWER AND REMOTE CONTROLS 04 001796 APPENDIX A9...

Страница 33: ...29 575 480 TRANSFORMER 04 001717 APPENDIX A10...

Страница 36: ...32...

Страница 37: ...33...