17

Bulletin HY22-3220A/US

Instruction Manual

550 Series Hydraulic Power Units

Troubleshooting

operating well because of worn orifices or seals.

Always remove and check the hot components first.

Check Oil Samples Periodically

Periodically checking oil temperature and siphoning an oil

sample from the reservoir, comparing it with a sample of new,

clean oil, is good preventive maintenance.

Oil that has been running too hot will look darker and feel

thinner than new oil. It will also smell burned. Normally it

will contain more contaminants, because hot oil leads to

accelerated wear of component parts.

Recommended Spare Parts

The only recommended maintenance component is the suction

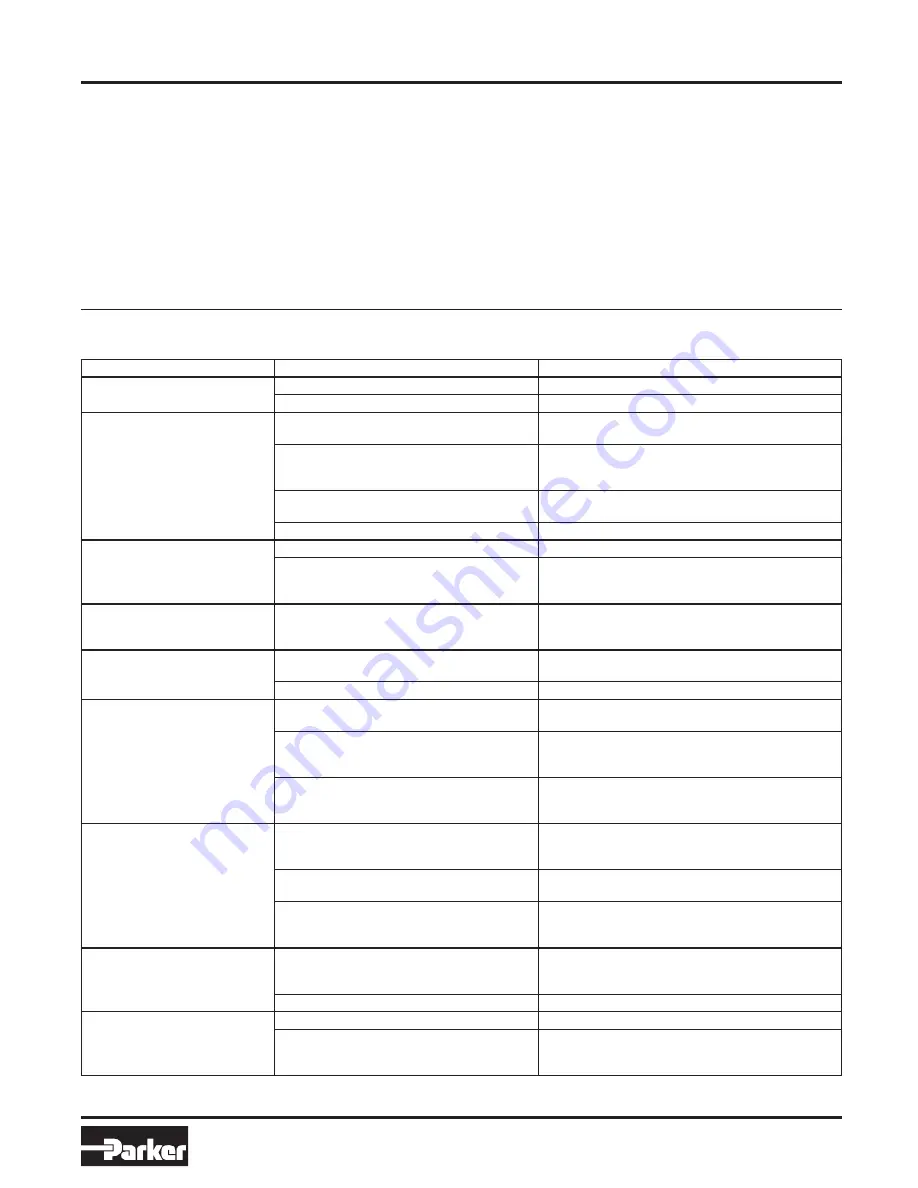

FAILURE MODE

CAUSE(S)

CORRECTIVE ACTION

Motor will not run

No power to the motor

Ensure proper voltage is available at motor

Motor is wired incorrectly

Wire the motor per the Installation instructions

Motor runs, but no flow

Reservoir does not have enough fluid

Fill the reservoir per the Installation instructions with an

approved fluid

Motor rotation is not clockwise from fan end

Single phase motors: wire per the Installation instructions

Three phase: interchange any two of the three power

leads

Two position/two way valve is not closed

If a normally open valve, energize to close. If a normally

closed valve, de-energize coil

D03/NG6 valve is not shifted from center position Energize one of the valve solenoids

Low flow

Incorrect pump was selected or installed

Contact your distributor for rework instructions

Relief valve is set too low for application allowing

bypass

Increase the relief valve setting ensuring the flow and

pressure output are still within the electric motor’s

capability

Reservoir overflows on cylinder

retract

Reservoir is too full. Filling the reservoir with

the actuators extended will cause an overflow

condition when actuators are retracted

Ensure that, with the system full of oil and the actuators

fully retracted, the reservoir is at the full condition

Motor gets hot/high current

draw

Motor is not wired per the Installation instructions Ensure proper voltage is available at motor

Wire the motor per the Installation instructions

Will not build pressure

Reservoir does not have enough fluid

Fill the reservoir per the Installation instructions with an

approved fluid

Motor rotation is not clockwise from fan end

Single phase motors: wire per the Installation instructions

Three phase: interchange any two of the three power

leads

Relief valve is set too low for application allowing

bypass

Increase the relief valve setting ensuring the flow and

pressure output are still within the electric motor’s

capability

Will not hold pressure

Circuit type selected will not hold pressure

Ensure the model code calls out the D1 circuit, the SW

circuit or an S_ or P_ circuit. Only these circuits are

designed to hold pressure

Two position/two way valve is not closed

If a normally open valve, energize to close. If a normally

closed valve, de-energize coil

D03/NG6 valve selected without the Manapak

check valve block

D03/NG6 directional valves are not designed to hold

pressure. Contact your Parker Oildyne distributor to

purchase a Manapak check valve manifold

Leaks at fittings

Hose ends/fitting adapters are not the correct

type for the 550 Series ports

For the D0 and D1 circuits, the power unit includes JIC-6

male extension fittings. For all other circuits, the power

unit has SAE-6 male ports

Fittings are not tightened properly

Ensure all fittings are properly tightened

Actuator will not move both ways

Valve coils are not energized properly

Ensure the directional valve coils are operating properly

Relief valve is set too low for application allowing

bypass

Increase the relief valve setting ensuring the flow and

pressure output are still within the electric motor’s

capability

strainer, Oildyne part number 410542. See the Maintenance

section on page 14 for instructions on replacing the suction

strainer.

Be aware of risk of hazards if poor quality replacement parts are

used or are obtained from an unauthorized source. Using non-

Parker supplied components will void the warranty.

Conclusive Unit Failure

If the operation of the unit cannot be restored after attempts at

the troubleshooting suggestions listed below, please contact

your local Parker distributor or the Oildyne Division directly to

arrange for warranty replacement/repair if within the warranty

period.

Troubleshooting

Parker Hannifin

HPS Division

New Hope, MN 55428 USA