➀

Introduction

3

TQ10 Step & Direction Drive – Description & Block Diagram

The TQ10SD Step & Direction Drive is a servo drive designed to run three phase brushless

DC servo motors equipped with Hall effect sensors. It can also operate brushed DC servo

motors.

The block diagram for a typical system is shown below.

Indexer

Motor

Motor

Currents

Step

Pulses

High Level

Commands

Host Computer

or

Programmable

Controller

TQ10

Step & Direction

Servo Drive

Hall & Motor Temp

Signals

Encoder

Signals

TQ10SD Step & Direction Drive – Block Diagram

The host computer or programmable controller may or may not be necessary, depending

upon the motion controller’s capabilities.

There are two circuit boards inside the TQ10SD—a

control board

and a

torque drive

board

. The control board takes in control signals, and transforms them into a torque

command. The drive board takes the torque command, and produces motor current in an

amount proportional to the command.

The TQ10SD generates a move profile based upon step and direction signals from the

indexer. For each step pulse received, the drive will make the motor turn one encoder

count. Incoming step pulses represent

commanded position

, and go into one of the inputs of

a summing node. Incoming encoder counts represent

actual position

, and go into the other

input of the summing node. During a typical move, actual position will differ from com-

manded position by at least a few encoder counts. Actual position is subtracted from

commanded position at the summing node—the result is

position error

. The TQ10SD

produces an error signal, an analog voltage proportional to the error. The error signal is

modified by the PID control loop, then continues to the torque drive circuit board as a

torque command

. The torque drive board is the same board that is used in the TQ10 Torque

Drive; for a description of how the torque command is transformed into motor current, see

the previous section describing the TQ10 Torque Drive.

Other Features – TQ10 & TQ10SD

Dip Switches

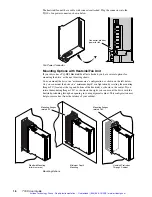

The TQ10 Drive (the name TQ10 now refers to both drives) has 12 DIP switches on the top

and three DIP switches on the bottom. You can set these switches to configure the drive for

your particular application.

Inputs and Outputs

All input and output signal connections are made on the front panel of the drive, through

removable screw terminal connectors.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com