8

Parker Hannifin Corporation

Bulletin TI-HFX-3D

Elevated Pressure

Applications

(>10 psig/0.7 barg)

The user must determine the nitrogen purity, flow rate, and pressure required by the application

prior to adjusting the system for desired outlet nitrogen purity and flow rate. The inlet air pressure

must be constant in order for the system to supply nitrogen of consistent purity to the application.

The inlet pressure to the Balston Nitrogen Generator should be maximized (within process and

generator parameters) to optimize the operation of the membrane module. The required inlet air

flow rate and all flow and purity specifications for different operating conditions are shown in the

specifications listing on pages 12-13.

Flow adjustments are made according to the values on the Nitrogen Purity label attached to the

front of the generator (and shown below).

If the Balston Nitrogen Generator is being used to deliver nitrogen at or near atmospheric pressure

(e.g. purging or blanketing applications), use the following procedure for start-up and adjustment of

the system.

1

1

1

1

1

Open the (customer installed) inlet air gate valve.

2

2

2

2

2

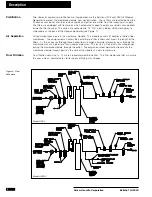

Adjust the (customer installed) inlet air pressure regulator until the Operating Pressure Gauge

(see Figure 1) shows the pressure reading required to achieve the purity and flow to match the

application (see Purity/Flow label above).

3

3

3

3

3

Adjust the Outlet Pressure Regulator (see Figure 1) until the Outlet Pressure Gauge reads less

than 10 psig (0.7 barg).

4

4

4

4

4

Consult the Nitrogen Purity Label on the control panel of the generator to determine the proper

flowmeter setting for the required process nitrogen purity and inlet air pressure. Adjust the flow

control valve on the control panel (see Figure 1) to yield the proper flowmeter reading.

5

5

5

5

5

Allow the system to reach equilibrium at the desired flowrate, pressure, and purity parameters.

This should take approximately 15 minutes.

6

6

6

6

6

Check the purity readings on the oxygen analyzer on a routine basis. If the nitrogen purity level

falls below the desired level, readjust the flow control valve until the proper nitrogen purity level is

reached. (Note: If more than minor adjustments of the flow control valve are required to reach

the desired purity level, please see the Troubleshooting section of this manual for further guid-

ance.)

If the Balston Nitrogen Generator is being used to deliver nitrogen at an elevated pressure

(>10 psig/0.7 barg), use the following procedure for start-up and adjustment of the system. (Note:

In elevated pressure applications, the customer should install a flow controller downstream from the

Nitrogen Generator.)

1

1

1

1

1

Open the (customer installed) inlet air gate valve.

2

2

2

2

2

Adjust the (customer installed) inlet air pressure regulator until the Operating Pressure gauge

(see Figure 1) shows the pressure reading required to achieve the purity and flow to match the

application (see Purity/Flow label, page 13).

3

3

3

3

3

Turn the Flow Control Valve to its fully open position

4

4

4

4

4

Set the Outlet Pressure Regulator (see Figure 1) to the desired outlet nitrogen pressure.

5

5

5

5

5

Consult the Nitrogen Purity Label on the control panel of the HFX0-3 to determine the proper

dimensionless flowmeter setting for the required process nitrogen purity and operating air

pressure. Adjust the (customer installed) flow controller until the dimensionless flowmeter shows

the correct reading (based on the Nitrogen Purity Label).

6

6

6

6

6

Allow the system to reach equilibrium at the desired flowrate, pressure, and purity parameters.

This should take approximately 15 minutes.

7

7

7

7

7

Check the purity readings on the oxygen analyzer on a routine basis. If the nitrogen purity level

falls below the desired level, readjust the downstream flow controller until the proper nitrogen

purity level is reached. (Note: If more than minor adjustments of the downstream flow controller

are required to reach the desired purity level, please see the Troubleshooting section of this

manual for further guidance.)

Operation: Adjustment Procedure

System Adjustment for

Desired Outlet Purity

Atmospheric Pressure

Applications

(<10 psig/0.7 barg)