ENGLISH

OPERATING AND MAINTENANCE MANUAL

4

DESCRIPTION

Portable air impact wrench designed for

motorsport application (Best Practice: Endurance,

IMSA, Le Mans Series and for all championships

that require the use of a wheel gun only).

LUBRICANT

Hammer mechanism lubrication: Special

grease for Paoli air impact wrench hammer

mechanism.

Air motor lubrication: Very fluid oil for air tools

or Special oil for Paoli air impact wrench motors.

ENVIRONMENTAL CONDITIONS

Temperature: -5 ° C ÷ + 45 ° C

Storage temperature: 0 ° C ÷ + 40 ° C

Air humidity: <80%

Max Altitude: 2000m from sea level

INTENDED USE

Assembly air tool for threaded fasteners in the

pit stop service.

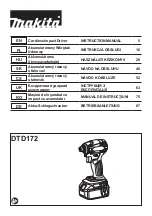

TECHNICAL DATA

Weight (kg)

3,68

Length (mm)

198

Square drive

1”

Air inlet

3/8” BSP

Supply hose inside diameter

1/2” (13 mm)

Maximum free speed (RPM)

14.300 (at 25 bar)

Max weight recommended

power socket (kg)

0,70

Operating air pressure (bar)

25 (maximum)

Ultimate torque* (Nm)

3.900

* These performances have been obtained after having tested the wheel gun on a testing-bench, that is on fixed bolts,

which have been tightened for 3 seconds. Please remind that, during the tightening/loosening on a Formula 1 car’s

wheel hub you lose most of the torque, due to the hub’s spin. Furthermore the performances change depending on the

wheel gun’s operating-time on each nut, reminding that the correct operating-time on one single nut is, on average,

less than one second.

L

It is recommended to use a whip hose

(flexible hose for compressed air with a

minimum length of 46 cm (18 inch)) with

a threaded male to connected to the air

inlet of the wheel gun, and a male quick

disconnect coupling at the other end.

L

Fit a the whip hose to the air pressure regulator

using a specific supply hose.

L

Use a supply pipe of minimum inner

diameter 13 mm (1/2 inch) suitable for its

intended use.

L

Use couplings with minimal nominal bore

10 mm (25/64 inch) suitable for their

intended use.

View figure Fig.3.

L

It is allowed to use exclusively on industrial

plants with compressed air.

L

Make use of a supply system that observes

the indicated pressure values (max 10%

over the maximum value indicated) using an

air pressure regulator supplied by a system

observing the current safety standard, and

that it is subjected to regular checks.

L

The components of the supply system must

be designed and constructed in accordance

with the safety requirements contained in

current international standards.

L

Before any work on the supply system, always

check that the line is depressurized (no air

pressure).

AIR SUPPLY SYSTEM DIAGRAM

Содержание DP 6000 BIAS

Страница 55: ...ATTACHMENTS TECHNICAL CHARTS 55...

Страница 56: ...ATTACHMENTS TECHNICAL CHARTS 56...

Страница 58: ...ATTACHMENTS TECHNICAL CHARTS 58 Fig 4 3 PORT GUN SELECTOR PLATE STANDARD CLOCKWISE ANTICLOCKWISE...

Страница 59: ...ATTACHMENTS TECHNICAL CHARTS 59 Fig 6...