Exceptional condition

•

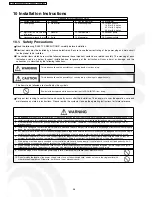

During vacuum pump delay ON within MOPMPS07 second in the start control

Outdoor air temp. T

EOTteisi

EOBENT04

T

EOBENS04

EOBENT05

T

EOBENT04

EOBENS05

EOBENT06

T

EOBENT05

EOBENS06

T

EOBENT06

EOBENS07

Detail Explaination for Specification

•

In order to blow out water from tube, 2 way valve is open before vacuum pump stop during stop operation. At this condition,

air flow increase 4 ~ 5 times, where indoor O

2

supply sound will increase but not noticeable at normal operation.

•

Freeze-up countermeasure (2 way valve)

In order to blow out residual moisture in tube during stop operation (flow velocity up, low humid air intake). Stop delaying

time change as the amount of dew formed depend on outdoor air temperature.

Date name

Description / Designation

Data

OTfan1

Outdoor fan delay stop time

30s

EOBENS04

Hi OD temp., stop control, pump & valve ON time

0s

EOBENS05

Me OD temp., stop control, pump & valve ON time

150s

EOBENS06

Lo OD temp., stop control, pump & valve ON time

150s

EOBENS07

SLo OD temp., stop control, pump & valve ON time

270s

EOBENT04

Stop control, Outdoor air temp.

10°C

EOBENT05

Stop control, Outdoor air temp.

2°C

EOBENT06

Stop control, Outdoor temp.

-3°C

•

Power relay delay stop time is 5 min during stop operation. Therefore maximum delay stop time is 270s.

F. Oxygen Enrich Freeze-Up Prevention Control

1. Control outline

•

To avoid water in tube from freeze-up during low outdoor temperature.

•

Only vacuum pump restart control of protection control is operating.

48

CS-XE9DKE CU-XE9DKE / CS-XE12DKE CU-XE12DKE

Содержание SUPER DELUXE CS-XE9DKE

Страница 10: ...4 Dimensions 10 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 11: ...11 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 12: ...5 Refrigeration Cycle Diagram 12 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 13: ...6 Block Diagram 13 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 14: ...7 Wiring Diagram 14 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 89: ...13 Technical Data 89 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 90: ...90 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 102: ...102 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 103: ...How to use electronic circuit diagram 103 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 104: ...18 1 Remote Control 104 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 105: ...18 2 Print Pattern Indoor Unit Printed Circuit Board Main 105 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...

Страница 107: ...18 5 Print Pattern Outdoor Unit Printed Circuit Board Main 107 CS XE9DKE CU XE9DKE CS XE12DKE CU XE12DKE...