14

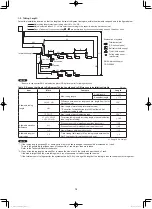

1-11. Installing Distribution Joint

(1) Refer to “HOW TO ATTACH DISTRIBUTION JOINT” enclosed with the optional distribution joint kit (CZ-P160BK2).

●

W

hen connecting a branch tubing to the indoor unit directly, it is necessary for each branch tubing to install at a positive angle with

respect to horizontal in order to prevent accumulation of refrigerant oil in stopped units. See the below chart.

B

ranch tubing system

R

estricted

Not restricted

A

B

How to install

branch tubing

When connecting branch tubing to indoor unit directly

When not connecting

branch tubing to

indoor unit directly

Gas tube

Liquid tube

Gas & liquid tubes

When connecting to A

When connecting to B

Horizontal

A

D

B

15

~

90°

Straight tubing

length over

200mm

Arrow view D

15

~

90°

15

~

30°

15

~

90°

15

~

30°

Straight tubing

length over

200mm

(Branch tubing

angle)

Horizontal

Straight tubing

length over 200mm

or

0

~

30°

(Branch tubing

angle)

Horizontal

Vertical

Upward

Vertical

Vertical

Vertical

Vertical

Downward

15

~

90°

Vertical

Straight tubing

length over

200mm

15

~

90°

Straight tubing

length over

200mm

Vertical

Vertical

Vertical

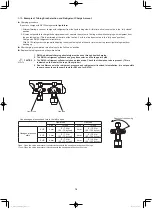

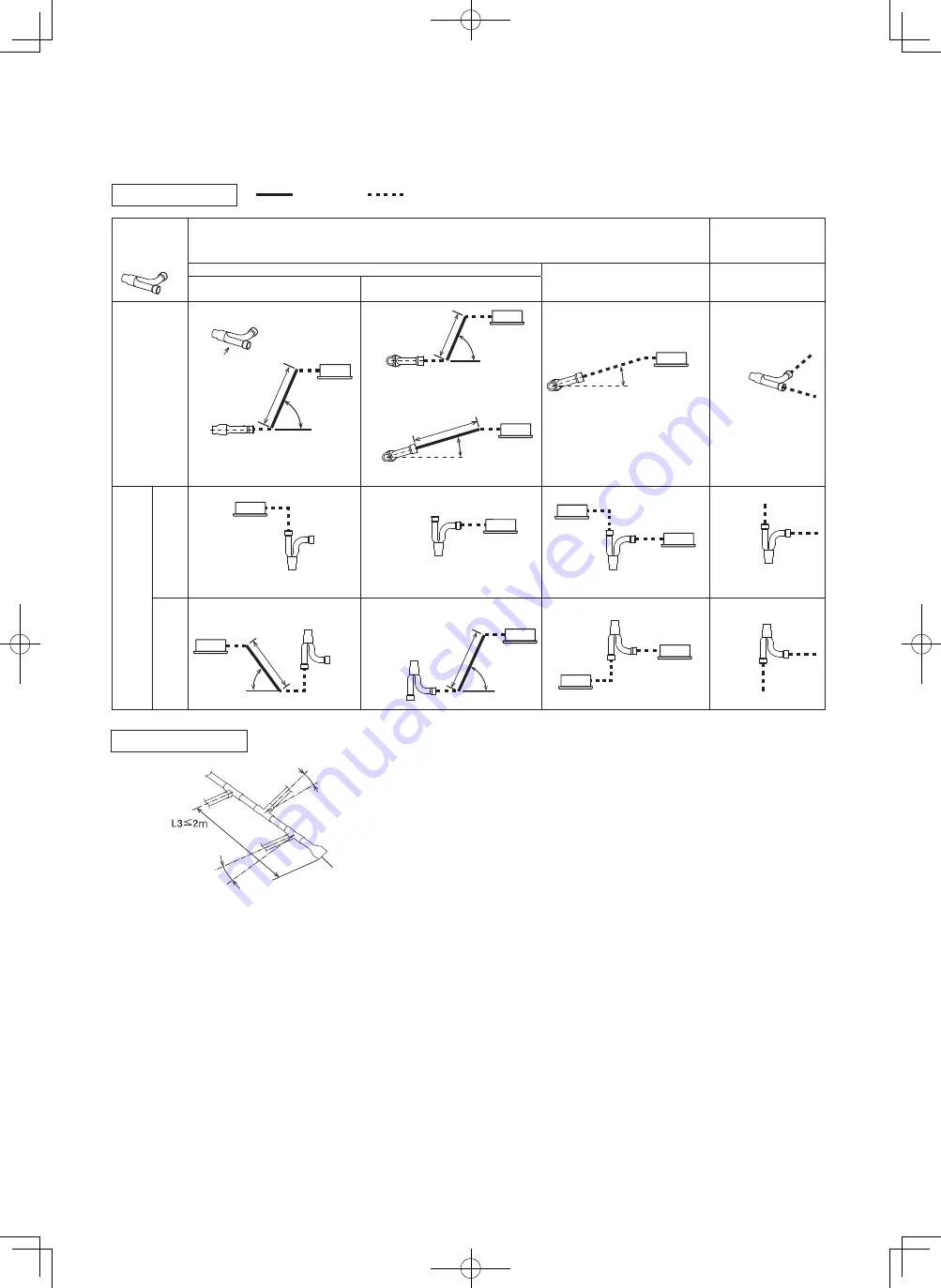

H

eader branch system (Main tubing is horizontal.)

O

utdoor

I

ndoor

I

ndoor

I

ndoor

(From 1st branch to tip

of solidly welded part)

H

orizontal line

H

orizontal line

Install at a positive angle

(15~30°)

Install at a positive angle

(15~30°)

●

B

e sure to solidly weld shut the T-joint end (marked by X in

the figure). In addition, pay attention to the insertion depth of

each connected tube so that the flow of refrigerant within the

T-joint is not impeded.

B

e sure to use a commercial available T-joint.

●

W

hen using the header joint system, do not make further

branches in the tubing.

S

olidly welded shut (X)

00_291827_2WAY_Eng.indb 14

2017/7/5 13:41:25