109

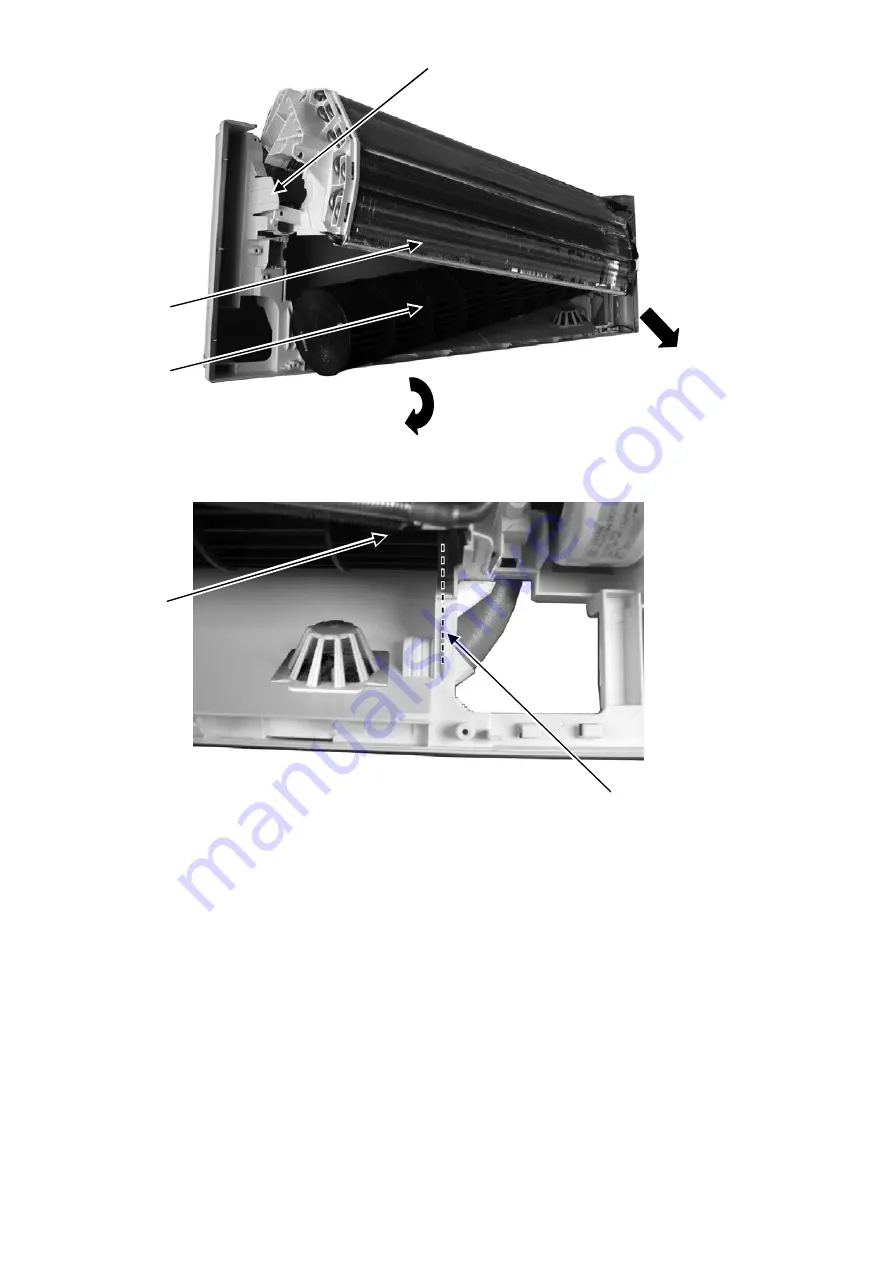

19. Push the holdfast to the left and lift up the evaporator.

21. Fan motor can be removed after the

removal of cross flow fan.

Reminder: To reinstall the fan motor, adjust

the fan motor connector to 45° towards you

before fixing control board.

20. Remove the cross flow fan from the unit by

pulling it to the left and downward.

Evaporator

Cross flow fan

Figure 9

Reminder: To reinstall the cross flow

fan, ensure cross flow fan is in line as

shown in figure 10.

Cross Flow Fan

Figure 10

Содержание CS-S9NKV

Страница 15: ...15 4 2 3 CU S18NKV CU S24NKV...

Страница 16: ...16 4 2 4 CU S28NKV...

Страница 17: ...17 5 Refrigeration Cycle Diagram 5 1 CS S9NKV CU S9NKV CS S12NKV CU S12NKV...

Страница 18: ...18 5 2 CS S18NKV CU S18NKV CS S24NKV CU S24NKV...

Страница 19: ...19 5 3 CS S28NKV CU S28NKV...

Страница 24: ...24 7 Wiring Connection Diagram 7 1 Indoor Unit 7 1 1 CS S9NKV CS S12NKV...

Страница 25: ...25 7 1 2 CS S18NKV CS S24NKV...

Страница 26: ...26 7 1 3 CS S28NKV...

Страница 31: ...31 8 Electronic Circuit Diagram 8 1 Indoor Unit 8 1 1 CS S9NKV CS S12NKV...

Страница 32: ...32 8 1 2 CS S18NKV CS S24NKV...

Страница 33: ...33 8 1 3 CS S28NKV...

Страница 41: ...41 9 1 5 Human Activity Sensor Printed Circuit Board...

Страница 42: ...42 9 2 Outdoor Unit 9 2 1 Main Printed Circuit Board 9 2 1 1 CU S9NK...

Страница 43: ...43 9 2 1 2 CU S12NK...

Страница 44: ...44 9 2 1 3 CU S18NK CU S24NK...

Страница 45: ...45 9 2 1 4 CU S28NK...

Страница 46: ...46 9 2 2 Noise Filter Printed Circuit Board 9 2 2 1 CU S9NKV...

Страница 47: ...47 9 2 2 2 CU S28NKV...