6

Gate and Platform Installation

Revision 1.3

- 17 -

PLATFORM WILL NOT TILT TO THE GROUND IF THESE WELDS ARE NOT REMOVED!

Operator must continue to hold down button/toggle after lift arms touch ground to allow platform tip

to tilt to the ground

Figure 14 Removing of swing fixture tack welds

11. Slide out upper parallel arm pin just enough to rotate coils springs into position for platform spring

assist per Figure 18.

- Do not power gate hard against bed extension while gate is only tack welded in position

12. Complete welding of gate. Weld all contact areas 100% with ¼” fillet or butt welds.

13. Adjust sliding bumper temporarily with a clamp so the platform is approximately 5 to 10 degree in

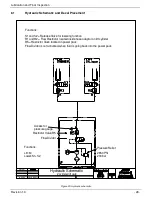

from vertical when resting against the wheel. Weld bumper with 3/16" weld 100%. (Fig. 12)

Figure 15 Platform roll over wheel adjustment

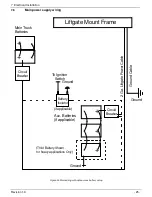

Figure 16 Frame captioning for tight storage of liftgate

14. Verify platform lowers without hanging up on wheel before welding. Slide wheel in slightly until

platform lowers smoothly

15. Install frame caps per chapter 4.2 or 4.6. (See Fig. 14 alternate frame modification)

16. Adjust (2) rubber snubbers up to force platform against frame caps to hold platform from bouncing

while vehicle is moving (See Fig. 1)

17. Check all contact areas if they are welded and polish them. There should not be any sharp corners

Grind off tack welds from both

knuckles (these are the only ones

which are not painted)

Knuckle is able to swing when platform

touches ground with tacks removed

Remove tack welds and slide

to achieve 5°-10°.

Verify platform will lower without

hang up before welding. Slide

tube slightly if platform does not

lower smoothly

5°-10°

Angle serves to hold body and

truck frame together as the

gate is very strong