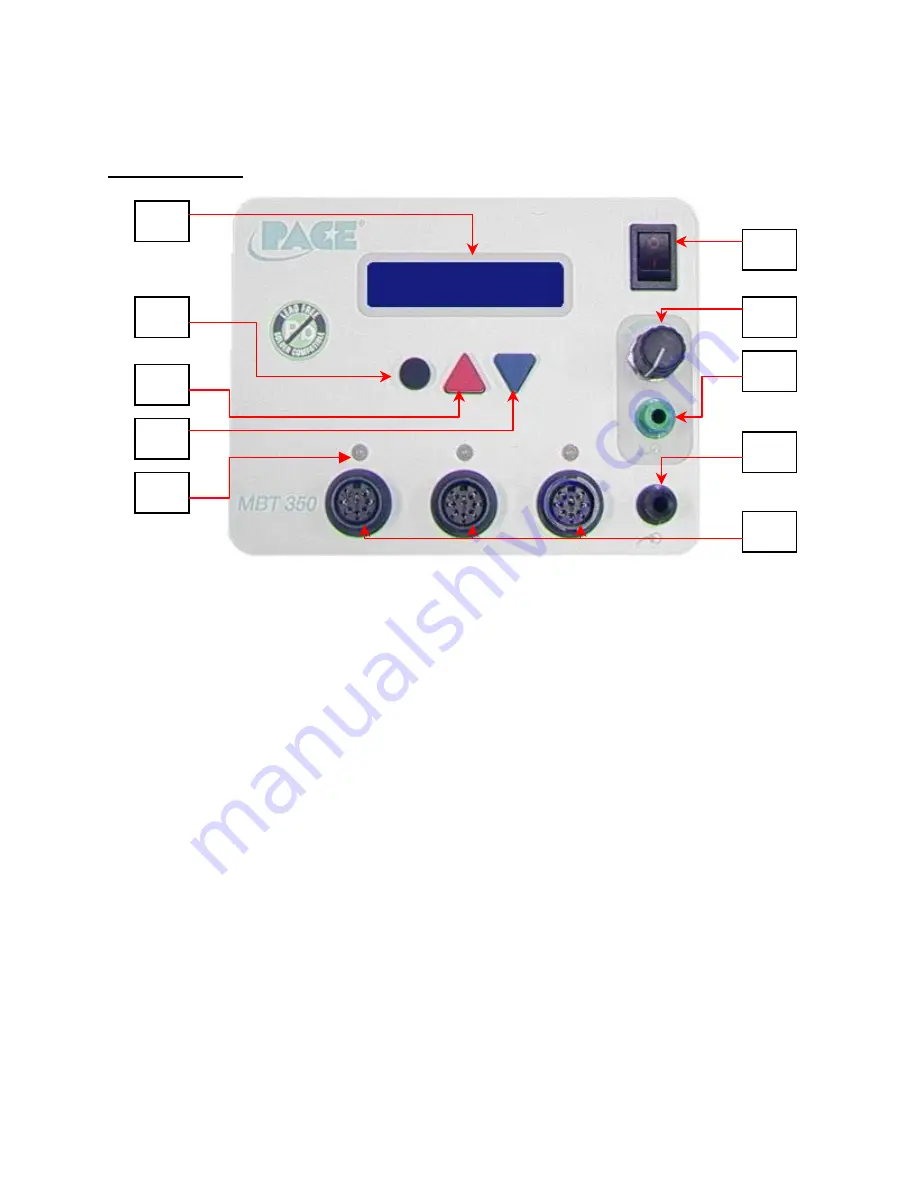

Parts Identification

6

2

3

4

7

8

9

5

Figure 1

1

10

Listed below is a description of the Control Panel features. Use Figures 1 & 2 as a guide.

1.

LCD DISPLAY

- Provides temperature information for all three channels. This includes: Operating Tip

Temperature in Temperature Display Mode (normal operation), Tip Offset Constant in Tip Offset Mode,

Set Tip Temperature in Tip Set Mode and other information in Calibration (CAL) Mode.

2.

PROGRAM KEY –

Access tip offset feature and scroll through system channels.

3.

SCROLL UP KEY

- Increases the Set Tip Temperature (in Tip Set Mode) and the Tip Offset Constant

(in Tip Offset Mode) in one, then ten-degree increments. Also used in (Calibration) Mode.

4.

SCROLL DOWN KEY

- Decreases the Set Tip Temperature (in Tip Set Mode) and the Tip Offset

Constant (in Tip Offset Mode) in one then ten-degree increment. Also used in “CAL” (Calibration) Mode

5.

LED; CH 1, CH 2 or CH 3 Illuminated LED’s change color to reflect handpiece connectivity. GREEN

(circuit complete) AMBER (in process) RED (no connection / error)

6.

POWER SWITCH

- Turns system ON ("1") and OFF ("0"); controls input power to the system.

7.

PRESSURE ADJUSTMENT

- Controls variable airflow pressure delivery.

8.

PRESSURE PORT

– Quick connect fitting with provides airflow for Mini ThermoJet handpiece (in Hot

Jet Mode) and Sodr-X-Tractor handpiece. Air pressure is present when handpiece finger switch or

optional foot pedal is actuated. Air pressure ceases 1.2 seconds after switch (or foot pedal) is released

9.

AUTO SNAP-VAC PORT

- Quick connect fitting provides quick-rise vacuum for Sodr-X-Tractor,

and ThermoPik handpieces. Vacuum is present when handpiece finger switch or optional foot pedal is

actuated. Vacuum ceases 1.2 seconds after switch (or foot pedal) released.

10.

CH 1 POWER RECEPTACLE

- Provides power, tip ground, sensing circuitry and finger switch

connection from MBT system to handpiece connected to Channel 1 (

CH 1

).

CH 2 POWER RECEPTACLE

- Provides power, tip ground, sensing circuitry and finger switch

connection from MBT system to handpiece connected to Channel 2 (

CH 2

).

CH 3 POWER RECEPTACLE

- Provides power, tip ground, sensing circuitry and finger switch

connection from MBT system to handpiece connected to Channel 3 (

CH 3

).

©2005 PACE Inc., Annapolis Junction, Maryland All Rights Reserved Page 5 of 19