- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

I

NSTRUCTION

M

ANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: [email protected] Web: http://www.metallographic.com

30

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

Polishing Head

Rough or planar grinding, is required to produce flat specimens and to reduce the damage created by

sectioning. The planar grinding step is accomplished by decreasing the abrasive grit particle size

sequentially to obtain surface finishes that are ready for polishing. Care must be taken to avoid being

too abrasive in this step, and actually creating greater specimen damage than produced during cutting.

This is especially true for very brittle materials such as ceramics and silicon.

The machine parameters which affect the preparation of metallographic specimens include: grinding /

polishing pressure, grinding direction, and the relative velocity distribution between the specimen and

the polishing wheel.

Grinding Speed

For automated polishing the relative speed between the polishing head and the polishing wheel has a

significant effect on the flatness of the mount, especially for grinding with coarse abrasives. As an

example, the following two conditions show the effect of running with the head and base speed in the

contra direction as well as running the head and base speeds in the same direction at the same speed.

Based on the relative velocity distributions for grinding / polishing the best condition for maintaining a

uniform velocity across the specimen as it rotates around the polishing wheel is to run them in the

same direction at the same speed. In addition, changing the offset as well as the combination speed

5.10.1 Rough / Planar Grinding

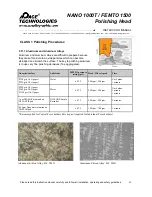

High relative velocity difference (contra)

between the polishing head and polishing base

Low relative velocity difference

(complementary) between the polishing head

and polishing base