- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

I

NSTRUCTION

M

ANUAL

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1 520-882-6598 Fax +1 520-882-6599 email: [email protected] Web: http://www.metallographic.com

29

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

NANO 1000T / FEMTO 1500

Polishing Head

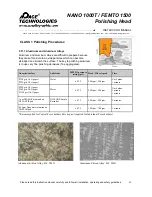

5.10 Metallographic Specimen Preparation Basics (continued)

A typical metallographic specimen preparation consists of the following basic steps:

Preparation Stage

Purpose

Initial documentation:

To document the initial condition of the sample,

To map the sample surface,

To highlight the area of interest.

Sectioning / cutting:

To reduce the size of large samples and to sample the

specimens close to the area of interest.

Rough, or planar grinding

(refer to Section 4.9.1):

To obtain a planar surface,

To remove sectioning damage,

To approach the area of interest.

Rough polishing (refer to

Section 4.9.2):

Ideally to remove all the subsurface damage and microstructural

damage produced during cutting and rough grinding (Superficial

scratches may still be present after this step).

Final polishing (refer to

Section 4.9.1)::

Generally, more for cosmetic purposes than for removing

microstructural damage. In most cases, this stage should be

minimized to avoid over polishing and distorting the

microstructural features.

Etching:

To enhance microstructural features such as grain boundaries,

grain size, phase differences, etc.

Examination:

A variety of examination techniques are used in metallography,

including: optical microscopy, electron microscopy and hardness

testing.