22

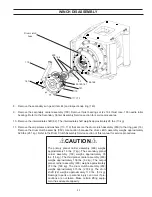

1. Remove the wire rope from the cable drum BEFORE disconnecting the hydraulic lines from the winch motor.

2. Drain the gear case oil as described in the Preventive Maintenance section of this manual.

3. Disconnect hydraulic and electrical lines from the winch to the tractor. Take precautions so that hydraulic oil does

not leak from the tractor hydraulic lines onto the ground. Cap or plug all connectors and ports to prevent leakage

and contamination.

4. Using caution, remove the winch from the tractor mounting brackets. Take note of the weight of the base winch from

the Specifications section of this manual. Use an appropriately sized crane and lifting equipment that can handle

the weight. It is recommended to use a lift plan to ensure safety during disassembly.

5.

Remove the hose guard (Item 179) from the left of the winch and disconnect the drum clutch hose.

6.

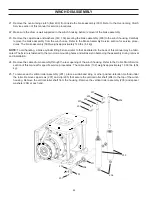

Remove the cap screws and washers (171, 172) that secure the end cover (167) to the ring gear assembly. Remove

the cover and inspect or replace O-ring (170). Remove the thrust bearing set (159 thrust race, 160 needle bearing,

and 161 thrust washer) from around the primary planet carrier hub. Remove the 20 drum clutch springs (151).

7.

Remove retaining rings (166) and primary sun gear (63). Remove the primary carrier assembly (600). Remove the

thrust bearing set (2x 168 thrust washers, 169 thrust bearing). Refer to the Primary Carrier Assembly Service sec

-

tion of this manual for service procedures.

WINCH DISASSEMBLY

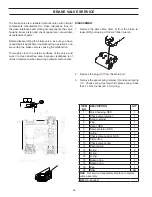

Oil fill

and vent

Oil drain

Oil level

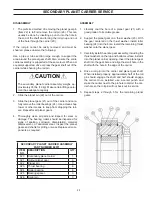

Needle roller thrust bearings are used throughout the

planetary reduction group. Handle these bearings

with care. If dropped, the metal cage separating the

rollers may be damaged, which will result in bearing

failure and possible damage to the winch gear train

if reused.

CAUTION

!

!