20

MAN 9063092 EN V1

P. Lindberg A/S

Sdr. Ringvej 1

www.p-lindberg.dk

Tlf: 70212626

DK-6600 Vejen

e-mail: [email protected]

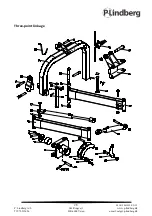

Adjusting and replacing a V-belt:

CAUTION

Belt drive system under spring tension; use care to avoid bodily harm!

The Belt tension should be checked after the first 20 hours of use. And then every 40

hours of use.

1.

Tension on the belt can be adjusted with the belt tension bolt. Turn the bolt until

desired tension is achieved. When the belt has the correct tension the gearbox should

be adjusted so that the gearbox extension is running straight (parallel) with the flail

mower. Loosen bolts at the bottom of the gearbox and move gearbox until gearbox

extension is running straight.

2.

Excessive tension on the belt may lead to premature failure of belt and drive

components.

It is important that the V-belt runs straight and smoothly to ensure correct operation.

If a pulley is not operating correctly, it may be necessary to adjust the pulleys on the

side. This is also necessary when replacing a pulley.

1.

Remove the pulley shield to see and work on the

pulleys and V-belts.

2.

The pulleys are mounted on the shaft with a taper

lock constructed of a two-part conical bushing which

holds the pulley in place and makes it possible to

adjust the wheel on the side of the shaft at the

same time.

The taper lock is held together by 6 or 8 bolts

(depending on the model). The taper lock also has 3

(or 4) holes which are empty.