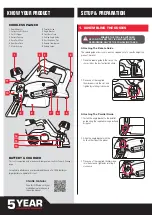

Planing Flat Surfaces

1. Set the required depth on the planer.

2. Adjust the parallel guide as

necessary.

Note:

For finishing surfaces, use

a low chip depth and make multiple

passes over the material.

3. Rest the front base plate

completely flat on the material

surface, ensuring the blades

are not in contact

with the

material. Hold the depth adjustor

with one hand and the trigger

handle with your dominant hand.

4. Switch on the planer and allow

the planer to reach maximum

speed.

5. Steadily push the planer over the

surface with both hands. Allow

the blades to do the work.

Note:

Ensure that both base

plates lie flat along the material

during planing.

Note:

Place more pressure on the rear base plate when lifting the planer

off the material. This will reduce the possibility of creating gouges as you

lift the planer off.

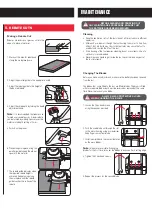

Chamfering Edges

The planer has a precision machined ‘V’ groove in the front base plate for

making 45° chamfers along the edges of your workpiece.

1. Set the required depth on the planer.

Note:

A layer of material will be removed

from the workpiece even if the cutting depth

is set to 0; always test the setting on a scrap

workpiece first.

2. Place the groove precisely on the

corner of the workpiece.

3. Plane along the edge of your

workpiece.

0.5

0

0.5

0

0.5

0

0.5

0

0.5

0

4. USING THE PLANER

PXPLS-082