PT-Link II N2-3

®

Technical Guide

PT-Link II N2-3 Interface

4

Setting Up Your PT-Link

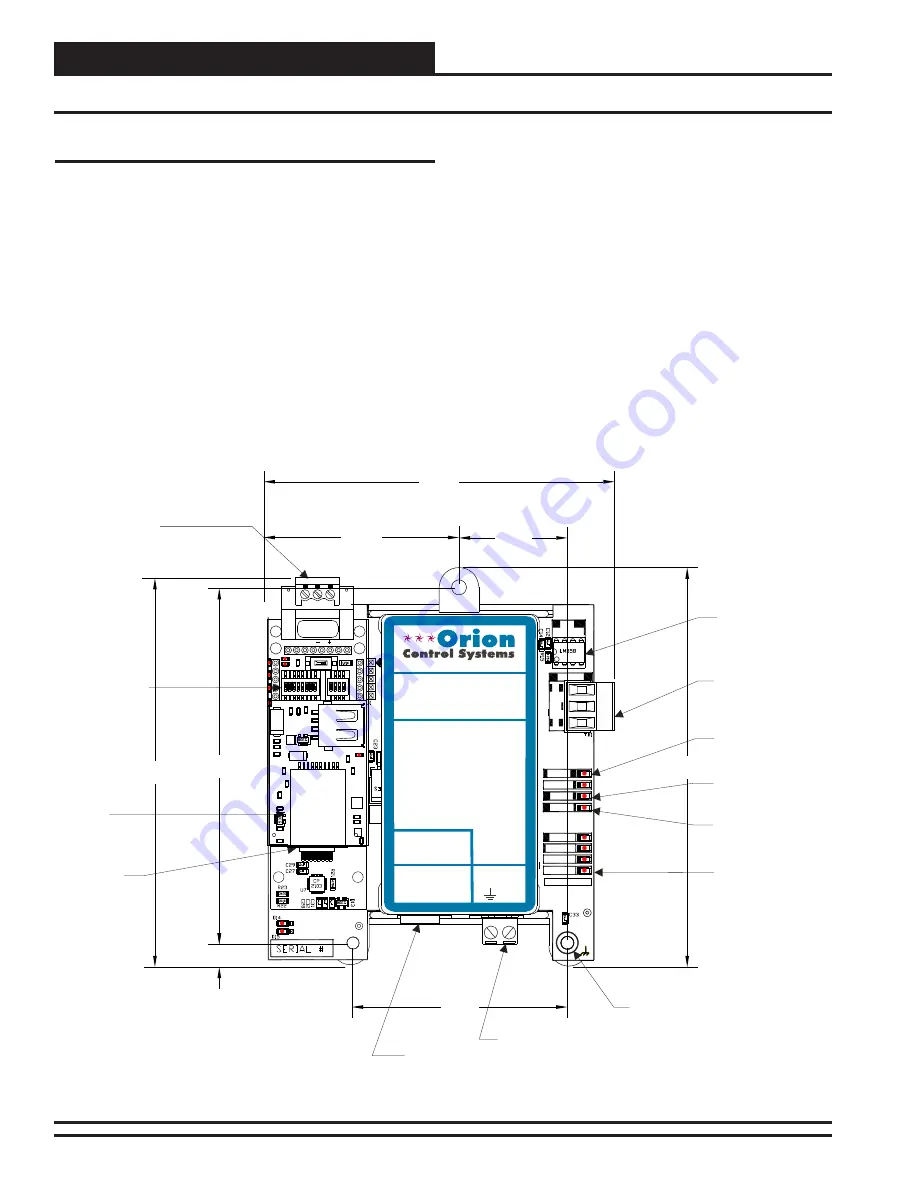

Figure 1: PT-Link II N2

®

Dimensions and Components

485

DRIVER

COMM

R

SH

T

LOOP

PROTO

LED1

LED2

TIMER

W_DOG

H-BEAT

POWER

MADE IN USA

4.82

4.70

0.27

4.31

1.31

2.61

4.25

2.37

N2

®

Communications

Wiring Terminal

N2

®

Protocessor

Module

Ethernet

Port

0.20 Dia.

Mounting Hole

Typ. 4 PL.

Local Loop

Communications

Wiring Terminal

Local Loop

Communications

Driver Chip

24 VAC Power

Terminal

Communications

LED

Diagnostic

LED #1

Diagnostic

LED #2

Power

LED

USB

Port

Configuration

DIP Switches

(Not Used)

IAEZH004

Made in USA

1

2

3

4

5

6

7

8

O

N

O

N

1

2

3

4

ON

RSGND

www.orioncontrols.com

WattMaster Label

#LB102080-01

Rev. 01A

OE368-23N-N2-3

PT-LINK II PROTOCOL

TRANSLATOR

FOR N2

+24

VAC

GND

LOOP

LED 1

LED 2

=RAPID BLINK

=BLINKS QTY

CONTROLLERS

= STEADY BLINK

PROTO

TIMER

WATCH DOG

H-BEAT

=RAPID BLINK

= STEADY BLINK

= ON SOLID

= STEADY BLINK

LED BLINK CODES (NORMAL)

Quick Start Guide

The following steps will get you up and running in no time:

1.

Familiarize yourself with the PT-Link II components (

Figure 1

).

NOTE:

The DIP Switches should be left in their default positon

which is all OFF. They are not used in this application.

2.

Connect your PT-Link II to the Controller(s) on your system

(up to four) and connect your PT-Link II to the N2-3 Network

(

Figure 2

).

3.

Copy the contents of the PT Link II CD to your PC’s Desktop.

You can also download the fi les from orioncontrols.com

under PT-Link II Setup Files. These fi les include RUINET.

4.

Connect your PT-Link II to your computer using an Ethernet

connection

(

Figure 3, page 6

).

5.

Change your PCs IP Address. Follow the directions that match

your current operating system - Windows XP, Vista, 7, 8 or 10.

See directions on

pages 7 & 8

.

6.

Obtain the following from your Building Automation System

Integrator: the N2-3 Device Instant Number (Client Node ID).

7.

Using FieldServer’s Graphical User Interface, edit the

Confi g.csv fi le and verify PT Link II communications.

Follow the directions on

pages 9-11

.

8.

If you run into any problems, follow the instructions in the

Troubleshooting section starting on

page 12

of this guide.