4

Power supply current capacity

Model

Input power

supply voltage

Power supply

current capacity

DG60

0.9 A or more

EAS4

1.4 A or more

EAS6

24 VDC±10%

3.1 A or more

CN1

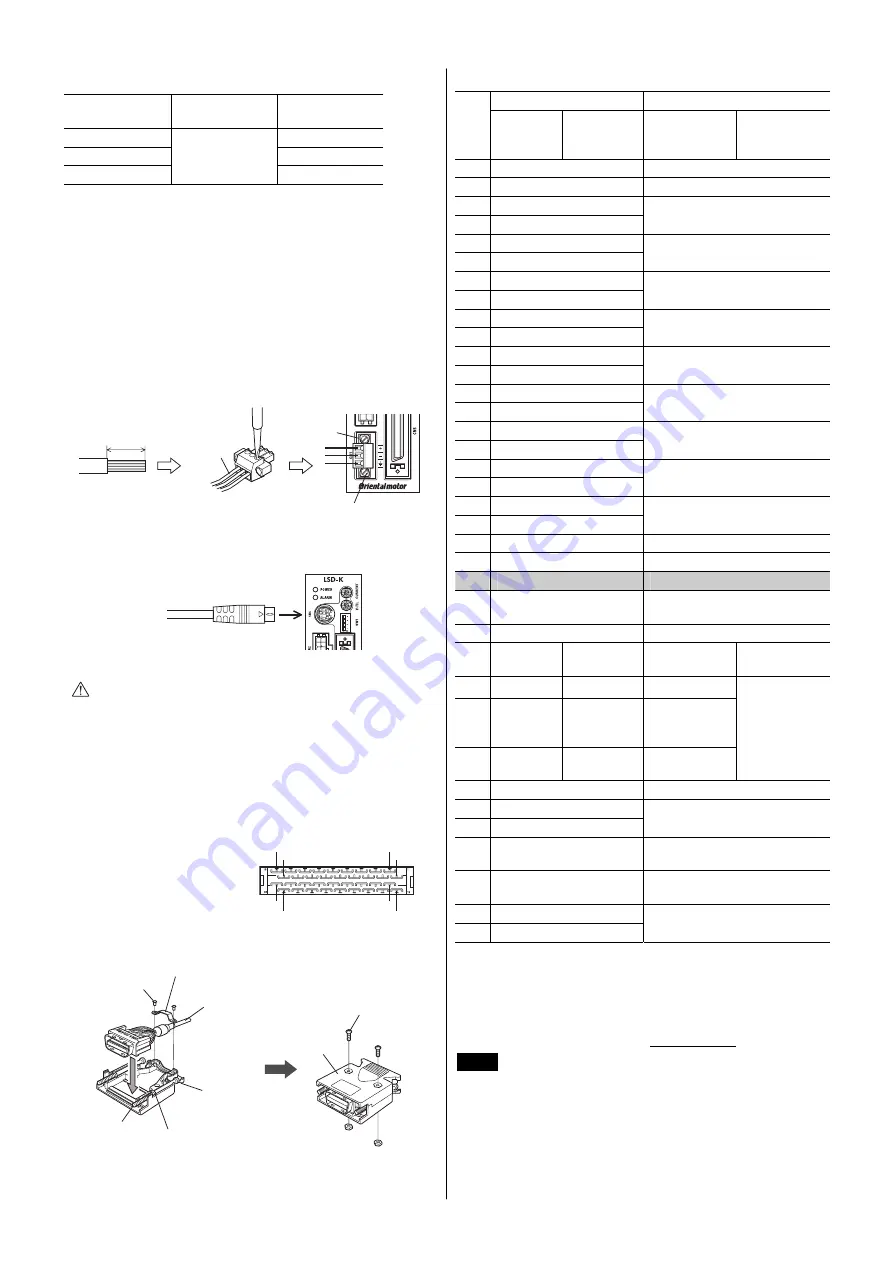

1.

Strip the insulation cover of the lead wire by 7 mm (0.28 in.)

2.

Insert each lead wire into the CN1 connector and tighten the

screw using a screwdriver.

Connector screw size: M2

Tightening torque: 0.22 to 0.25 N·m (31 to 35 oz-in)

3.

Insert the CN1 connector into CN1 on the driver and tighten the

screws.

Connector screw size: M2.5

Tightening torque: 0.4 N·m (56 oz-in)

7 mm (0.28 in)

CN1 connector

Tightening torque: 0.4 N·m (56 oz-in)

Lead wire

CN1

CN4

Connect to CN4

Cable for

OPX-2A

or

communication cable for data

setting software

Caution

The power supply connector (CN1), data edit

connector (CN4) and I/O signals connector (CN5)

are not electrically insulated. When grounding the

positive terminal of the power supply, do not

connect any equipment (PC, etc.) whose negative

terminal is grounded. Doing so may cause the

driver and these equipment to short, damaging

both.

CN5

Connector pin assignment

(viewed from soldering side)

1

2

17

18

19

20

35

36

•

Assembling the connector

I/O signal cable

Cable clamp

Screw (M2.5)

Case

Connector

Place the spring

washer outside

the case.

Screw (M2)

Screw (M2.5)

Tightening torque:

0.5 to 0.55 N·m

(71 to 78 oz-in)

Align the washer in the

depression in the case.

•

Pin assignment

Operating

mode

Name

Pin

No.

Positioning

operation

Push-motion

operation

∗

1

∗

3

Positioning

operation

Push-motion

operation

∗

1

∗

3

1

−

−

2 GND

Ground

connection

3 ASG+

4 ASG

−

A-phase pulse output

(Line driver)

5 BSG+

6 BSG

−

B-phase pulse output

(Line driver)

7 TIM1+

8 TIM1

−

Timing output (Line driver)

9 ALM+

10

ALM

−

Alarm output

11

WNG+

12

WNG

−

Warning output

13

END+

14

END

−

Positioning completion output

15

READY+/AL0+

∗

1

16

READY

−

/AL0

−

∗

1

Operation ready complete

output/Alarm code output 0

17

TLC+/AL1+

∗

1

18

TLC

−

/AL1

−

∗

1

Torque limit output/

Alarm code output 1

19

TIM2+/AL2+

∗

1

20

TIM2

−

/AL2

−

∗

1

Timing output (Open collector)/

Alarm code output 2

21

GND Ground

connection

22

IN-COM Input

common

23

C-ON

∗

2

Current ON input

24

CLR/ALM-RST

Deviation clear input/

Alarm reset input

25

CCM

Current control mode ON input

26

CS

T-MODE

∗

1

∗

3

Resolution

selection input

Push-motion

operation ON

27

−

M0

∗

1

∗

3

−

28

RETURN

M1

∗

1

∗

3

Return to

electrical home

operation

29

P-RESET

M2

∗

1

∗

3

Position reset

input

Push-current

setting

selection input

30

FREE Excitation

OFF

31

CW+/PLS+

32

CW

−

/PLS

−

CW pulse input/

Pulse input (+5 V or line driver)

33

CW+24 V/PLS+24 V

CW pulse input/

Pulse input (+24 V)

34

CCW+24 V/DIR+24 V

CCW pulse input/

Direction input (+24 V)

35

CCW+/DIR+

36

CCW

−

/ DIR

−

CCW pulse input/ Direction input

(+5 V or line driver)

∗1

The signal will become effective if the applicable setting has been

changed using the

OPX-2A

or

MEXE02

.

∗2

Factory setting of the C-ON input logic is "normally open." Be sure to

turn the C-ON input ON when operating the actuator. Set the C-ON input

logic to "normally closed" when the C-ON input is not used.

∗3

These signals are used to perform push-motion operation. Do not set

with the

DG

Ⅱ

Series. Refer to the USER MANUAL for details.

Note

•

The driver I/O signals of the

DG

Ⅱ

Series and

EAS

Series are in common with those of the

AR

Series,

but the signals are not compatible with the drivers of

other series. Do not connect the I/O signals with pin

assignments of other series.

•

Do not perform push-motion operation or sensorless

return-to-home operation with the

DG

Ⅱ

Series.

Doing so may result in damage to the actuator.