Speed Contr

ol S

y

st

ems

B-152

ORIENTAL MOTOR GENERAL CATALOG

2009/2010

Features B-138

/

System Configuration B-139

/

Product Line B-140

/

Specifications B-141

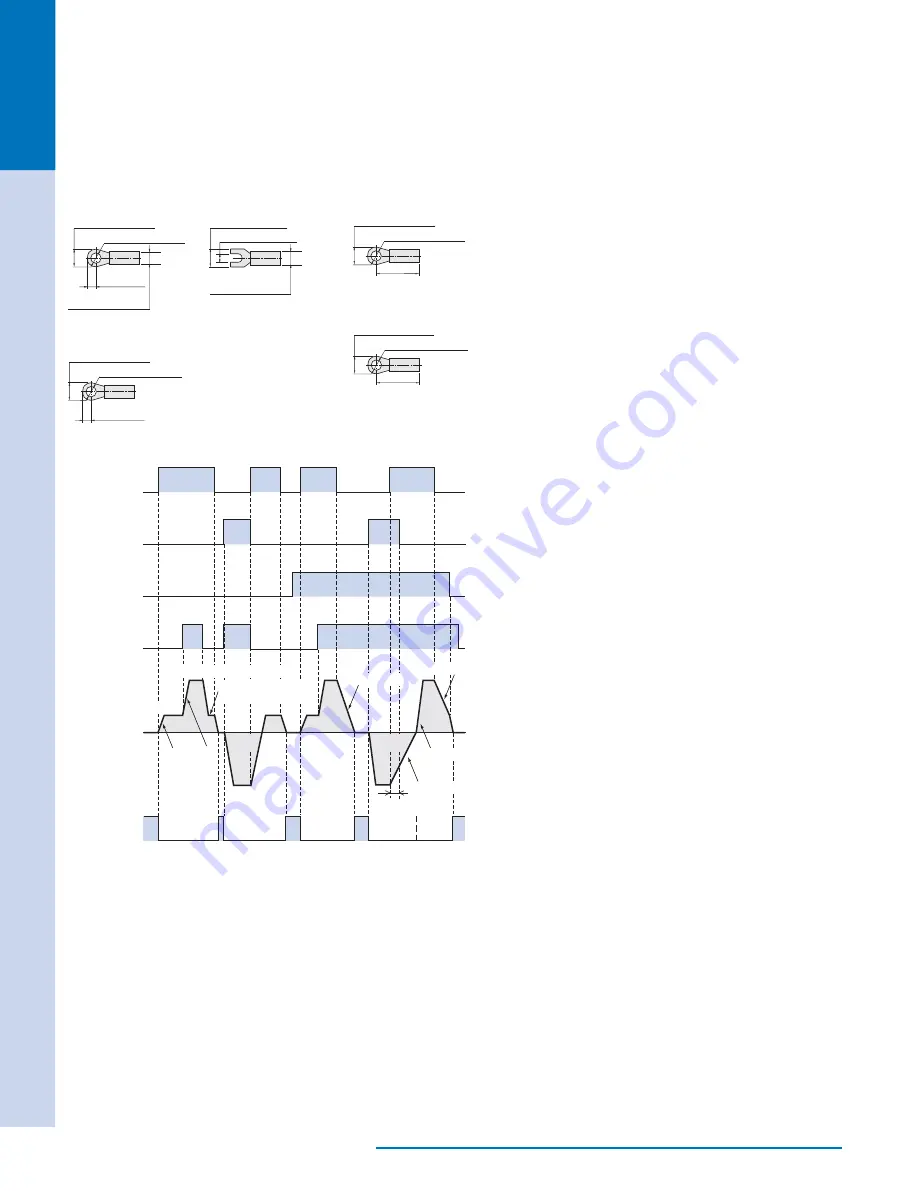

Connecting the Motor and Speed Controller

◇

A motor cable is not supplied with the product. Please purchase the appropriate cable.

●

Connecting the Motor

[Applicable lead wires]

AWG18 (0.75 mm

2

) min.

[Applicable Crimp Terminals]

Use a crimp terminal for the electromagnetic brake type.

•

Terminal Block

Round Terminal with Insulation

U-Shape Terminal with Insulation

ϕ

3.6 mm (

0.14

in.) min.

3.8 mm

(

0.15

in.) max.

7.2 mm (

0.28

in.) max.

after crimp

6.2 mm (

0.24

in.) max.

after crimp

6.2 mm (

0.24

in.) max.

6.2 mm (

0.24

in.) max.

3.6 mm (

0.14

in.) min.

•Protective Earth Terminal

Round Terminal with Insulation

ϕ

4.1 mm (

0.16

in.) min.

4.8 mm

(

0.19

in.) max.

9.5 mm (

0.37

in.) max.

Timing Chart

●

500 r/min

(Internal potentiometer)

CW input

CCW input

SD input

MO input

Motor operation

Electromagnetic

Brake

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Release

Release

Release

Release

Release

CW

CW

CW

CW

CCW

CCW

1500 r/min (External potentiometer)

500 r/min

(Internal potentiometer)

Acceleration

Acceleration

Deceleration

✽

1

✽

2

Deceleration

Deceleration

1

✽

The motor will stop if the CW and CCW inputs are simultaneously turned to ON.

2

✽

The electromagnetic brake may be left released when the motor runs and/or stops in

a short cycle or a shorter time is set for the acceleration/deceleration time.

The CW input signal, CCW input signal, M0 input signal

●

and SD input signal can be used to control all motor

operations, such as run, stop, direction switching, speed

switching.

Switching the CW input ON will cause the motor to

●

turn clockwise as viewed from the motor shaft, while

switching the CCW input ON will cause the motor to turn

counterclockwise. Switching each signal OFF will stop the

motor. The motor will start at the rise time corresponding to

the time set on the acceleration time potentiometer.

Switching the M0 input ON select the speed set on the

●

external speed potentiometer. Switching the M0 input OFF

will cause the motor to operate at the speed set on the

internal speed potentiometer. The timing chart shown left is

based on an internal speed potentiometer setting of

500 r/min and an external speed potentiometer setting of

1500 r/min.

If the motor is stopped with switching the SD input ON,

●

the motor stops at the time set by the deceleration time

potentiometer.

To release the electromagnetic brake when the motor is

●

stopped, turn the FREE (electromagnetic brake release)

input ON. This releases the electromagnetic brake and

allow the motor’s output shaft to turn freely. (This function

is available only with a speed control system with an

electromagnetic brake.)

Note:

Ensure that the temperature of the motor case does not exceed 90˚C (194˚F).

●

●

Connecting the Speed Controller

[Applicable lead wires]

AWG18 (0.75 mm

2

) min.

[Applicable Crimp Terminals]

•

Power Connection Terminal,

Motor Connection Terminal

Round Terminal with Insulation

ϕ

3.2 mm (

0.13

in.) min.

9 mm

(

0.35

in.) min.

6.2 mm (

0.24

in.) max.

•Protective Earth Terminal

Round Terminal with Insulation

ϕ

4.3 mm (

0.17

in.) min.

17 mm

(

0.67

in.) min.

8.5 mm (

0.33

in.) max.

Input/Output Signal Terminals

When a crimp terminal is used for connection,

use such terminals as shown below.

Manufacturer: Phoenix Contact

AI

0.25-6

Applicable wire size: AWG24 (0.2 mm

2

)

AI

0.34-6

Applicable wire size: AWG22 (0.3 mm

2

)

AI

0.5-6

Applicable wire size: AWG20 (0.5 mm

2

)