2

Precautions for use

This section covers restrictions and requirements the user should consider when using the

product.

Be sure to match the motor output power with the driver output power.

Wiring

z

Connecting the motor and driver

To connect the motor and driver, always use the dedicated connection cable (sold

separately).

z

How to fix the cable

Fix the cable at the positions near the connector so that no stress is applied on the

connector part.

A wide clamp is also available to use

When the cable is moved, it

causes the connectors to move,

causing stress to apply on the

connector part.

Fix using two banding bands

or a wide clamp.

•

Fixing at one place on each side

•

Fixing at two places on each side

Connector

Connector

Banding band, etc.

Banding band, etc.

When installing the motor on a moving part, use a flexible cable offering excellent flexibility.

Installation

z

Make sure not to hit or apply a strong impact on the motor output shaft or

the encoder.

Applying a strong impact on the motor output shaft or the encoder

may cause encoder damage or motor malfunction.

z

Grease measures

On rare occasions, grease may ooze out from the gearhead. If there is concern over

possible environmental damage resulting from the leakage of grease, check for grease

stains during regular inspections. Alternatively, install an oil pan or other device to prevent

damage resulting from contamination. Grease leakage may lead to problems in the user’s

equipment or products.

z

When using in low temperature environment

When an ambient temperature is low, a load torque may increase due to the oil seal

or viscosity of grease used in the gearhead, and the output torque may decrease or

an overload alarm may be generated. However, as time passes, the oil seal or grease is

warmed up, and the motor can be operated without generating the overload alarm.

z

Apply grease to the hollow output shaft of a hollow shaft flat gearhead.

When using a hollow shaft flat gearhead, apply grease (molybdenum disulfide grease,

etc.) on the surface of the load shaft and inner walls of the hollow output shaft to prevent

seizure.

Insulation resistance measurement and dielectric strength test

z

Do not conduct the insulation resistance measurement or the dielectric

strength test with the motor and driver connected

Conducting the insulation resistance measurement or the dielectric strength test with the

motor and driver connected may result in damage to the product.

z

Do not conduct the insulation resistance measurement or dielectric strength

test on an encoder.

Doing so may damage the product.

Operations

z

Use an electromagnetic brake motor in an application of vertical drive such

as elevating equipment.

When the motor is used in an application of vertical drive such as elevating equipment

(lifting and lowering device), use an electromagnetic brake motor so that the load can be

held in position.

z

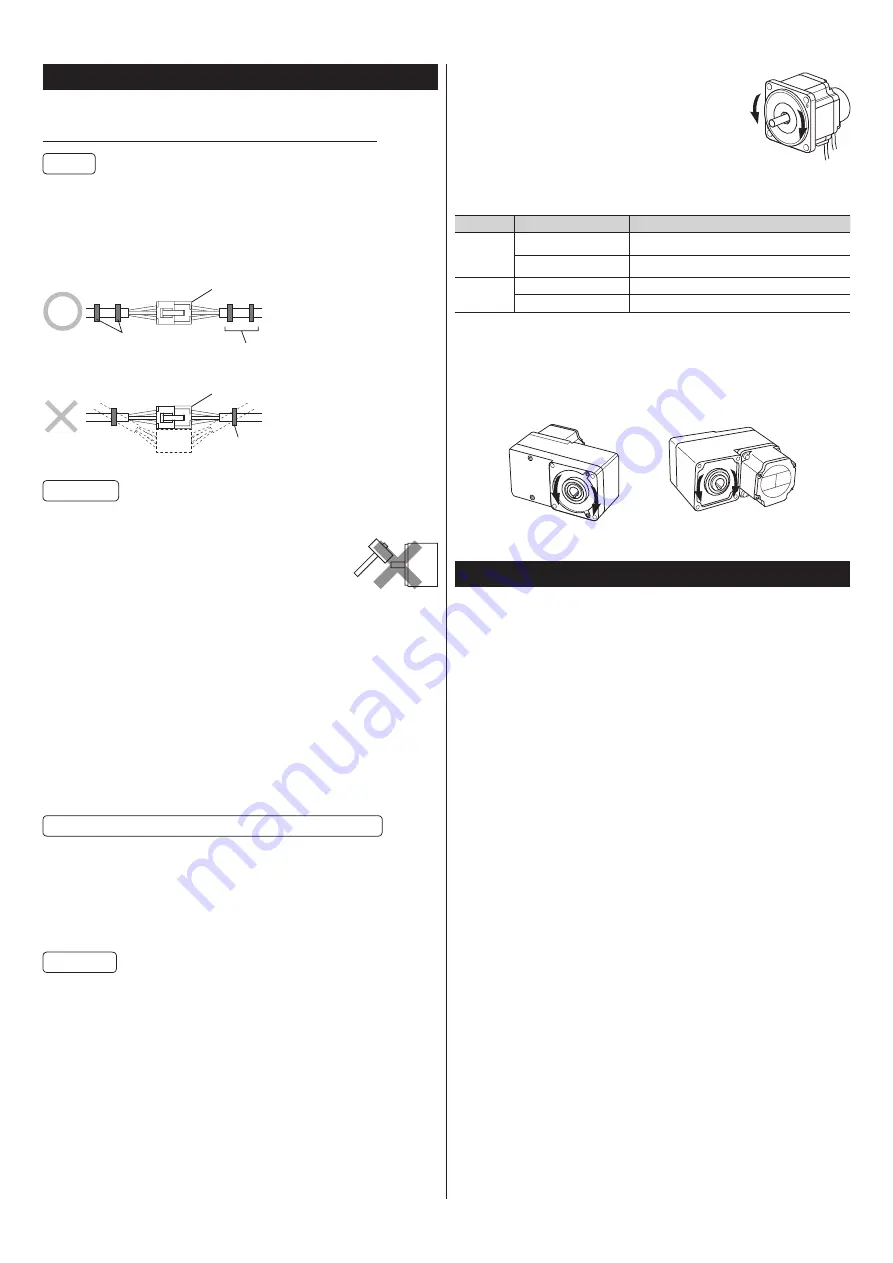

Rotation direction

The rotation direction of the motor output shaft can

be changed by setting of the “Motor rotation direction”

parameter.

The figure shows an example when the parameter is the

initial value.

RVS input

FWD input

•

Combination type-parallel shaft gearhead

The rotation direction of the gearhead output shaft may vary with that of the motor output

shaft depending on the gear ratio of the gearhead.

Model

Gear Ratio

Rotation direction of the gearhead output shaft

BXM230

BXM460

BXM5120

5

,

10

,

15

,

20

,

200

Same direction as the motor

30

,

50

,

100

Opposite direction to the motor

BXM6200

BXM6400

5

,

10

,

15

,

20

,

100

,

200

Same direction as the motor

30

,

50

Opposite direction to the motor

•

Combination type-hollow shaft flat gearhead

At all gear ratios, the output shaft rotates in the opposite direction to the motor as viewed

from the gearhead front side.

The rotation direction is different depending on whether the pre-assembled motor/

gearhead is viewed from the front side or rear side.

Check with the figure below.

Viewed from front side

Viewed from rear side

FWD input

RVS input

FWD input

RVS input

Checking the product

This section explains the items you should check, as well as the name of each part.

Package contents

Verify that the items listed below are included. Report any missing or damaged items to

the branch or sales office from which you purchased the product.

z

Combination type-parallel shaft gearhead

Motor ...............................................................1 unit (a gearhead is pre-assembled)

Mounting screw ...........................................1 set

(hexagonal socket head screw, plain washer, spring washer, nut each 4 pcs,

parallel key 1 pc

*

)

Operating manual (this document) ......1 copy

*

For the 200 W and 400 W types, the parallel key is fixed to the gearhead output shaft.

z

Combination type-hollow shaft flat gearhead

Motor ...............................................................1 unit (a gearhead is pre-assembled)

Mounting screw ...........................................1 set

(hexagonal socket head screw, plain washer, spring washer, nut

*

each 4 pcs,

parallel key 1 pc)

Safety cover ...................................................1 set

(safety cover 1 pc, mounting screw for safety cover 2 pcs)

Operating manual (this document) ......1 copy

*

For the 200 W and 400 W types, nuts are not included.

z

Round shaft type

Motor ...............................................................1 unit

Operating manual (this document) ......1 copy