ORGAPACK OR-T 50

23

12.06/WE

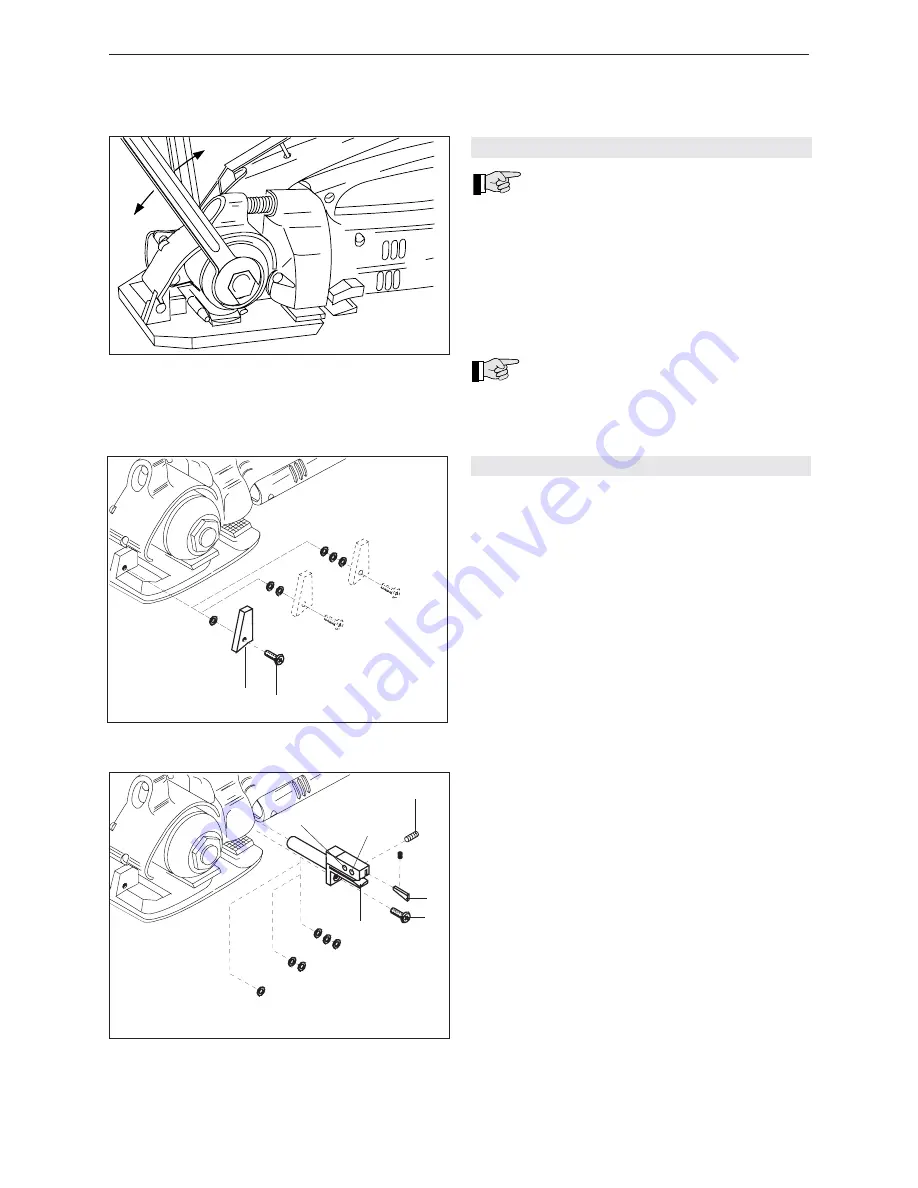

7.4 ADJUSTING STRAP WIDTH

– To change the strap width, the strap stop (16/2)

must be removed with the screw (16/1) from the tool

and refi tted with washers (1.5 mm thick) according to

the width of the strap.

– Strap width 19 mm (

3

/

4

“) one washer

– Strap width 15–16 mm (

5

/

8

“) one washer

– Strap width 12–13 mm (

1

/

2

“) two washers

– Strap width 9–10 mm (

3

/

8

“) three washers

– Loosen screw (17/4) and remove knife bushing

(17/1).

– Remove pin screw (17/2) and move the pawl (17/3)

to desired position according to strap width. Tighten

pin screw (17/2)

– Insert washers between base plate and knife

bushing according to strap width.

– Tighten screw (17/4).

– Strap width 19 mm (

3

/

4

“) one washer

– Strap width 15–16 mm (

5

/

8

“) one washer

– Strap width 12–13 mm (

1

/

2

“) two washers

– Strap width 9–10 mm (

3

/

8

“) three washers

7.3 ADJUSTING STRAP TENSION

The maximum strap tension is determined

by the adjustment of the friction clutch. For

this reason two fork wrenches are supplied.

– Block the tension shaft with the small fork wrench

(SW

11).

– With the other fork wrench (SW 17) adjust the nut.

– Turning the nut in clockwise direction the strap

tension is increased.

– Turning the nut in counterclockwise direction the

strap tension is reduced.

Best results are achived by adjusting the

clutch to the maximum tension for the pa-

ckage being strapped. But not as tight that the tensi-

on wheel will turn over or the strap breaks.

Fig. 15

17

+

–

Fig. 17

10 mm

13 mm

16/19 mm

1

2

3

4

10/13 mm

16/19 mm

Fig. 16

10 mm

13 mm

16/19 mm

2

1