(1) Use G9SX-SM

within an enclosure with IP54 protection or higher

according to IEC/EN60529. Be sure to connect the enclosure to earth(PE).

(2) Incorrect wiring may lead to loss of safety function. Wire conductors

correctly and verify the operation of G9SX-SM

before using the system

in which G9SX-SM

is incorporated.

(3) Do not apply DC voltages exceeding the rated voltages, nor any AC

voltages to G9SX-SM

. Do not connect to DC distribution network.

(4) Use DC supply satisfying requirements below to prevent electric shock.

- DC power supply with double or reinforced insulation, for example,

according to IEC/EN60950 or EN50178 or a transformer according to

IEC/EN61558.

- DC supply satisfies the requirement for class 2 circuits or limited

voltage/current circuit stated in UL 508.

(5) Apply properly specified voltages to G9SX-SM

inputs.

Applying inappropriate voltages cause G9SX-SM

to fail to perform its

specified function, which leads to the loss of safety functions or damages

to G9SX-SM

.

(6) Auxiliary error outputs and auxiliary monitoring outputs are NOT safety

outputs.

Do not use auxiliary outputs as any safety output.

Such incorrect use causes loss of safety function of G9SX-SM

and its

relevant system.

(7) After installation of G9SX-SM

, qualified personnel should confirm the

installation, and should conduct test operations and maintenance.

The qualified personnel should be qualified and authorized to secure the

safety on each phases of design, installation, running, maintenance and

disposal of system.

(8) A person in charge, who is familiar to the machine in which G9SX-SM

is

to be installed, should conduct and verify the installation.

(9) G9SX-SM

determines that motor stops when the standstill detection

input voltage is predetermined value or less. According to the

characteristic or load condition of motor, it may turn on safety detection

outputs before motor stops completely. In that case, before operation, the

qualified personnel should verify that risk of the rotation condition after

output is acceptable.

(10) Perform daily and 6-month inspections for the G9SX-SM

. Otherwise,

the system may fail to work properly, resulting in serious injury.

(11) Do not dismantle, repair, or modify G9SX-SM

. It may lead to loss of its

safety functions.

(12) Use only appropriate components or devices complying with relevant

safety standards corresponding to the required level of safety categories.

Conformity to requirements of safety category is determined as an entire

system.

It is recommended to consult a certification body regarding assessment

of conformity to the required safety level.

(13) OMRON shall not be responsible for conformity with any safety

standards regarding to customer's entire system.

(14) Disconnect G9SX-SM

from power supply when wiring. Devices

connected to G9SX-SM

may operate unexpectedly.

(15) Be cautious not to have your fingers caught when attaching terminal

sockets to the plugs on G9SX-SM

.

(16) Do not use in combustible gases or explosive gases.

(17) Driving voltage of the motor is impressed to the standstill detection

inputs. Connect overcurrent protective equipment; fuse, circuit-breaker

etc., (3A Max.) and tighten the wirings by rated tightening torque to the

standstill detection inputs.

Precautions for Safe Use

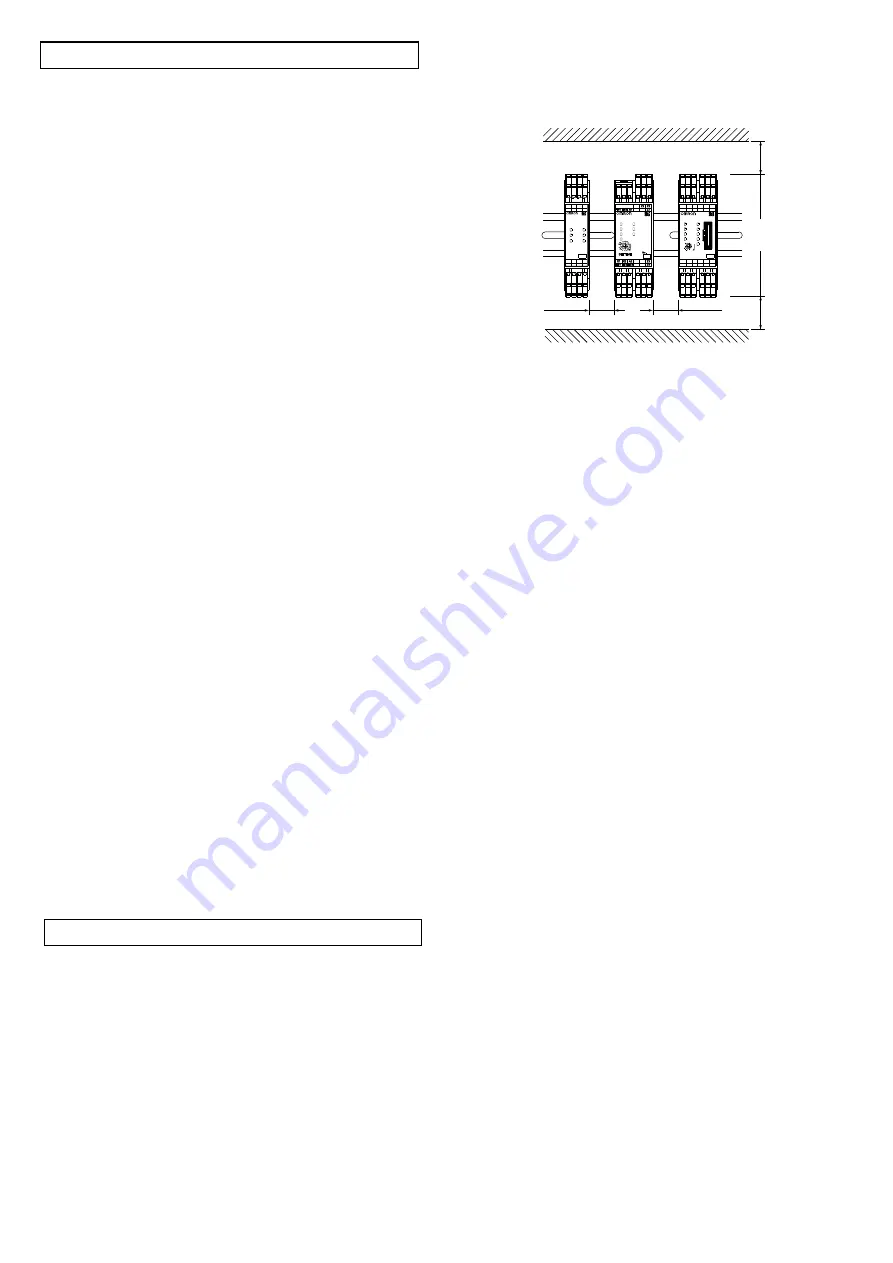

(4) Following spacing around G9SX should be available to apply rated

current to outputs of G9SX and for enough ventilation and wiring:

1) At least 25 mm beside side faces of G9SX.

2) At least 50 mm above top face of G9SX and below bottom face

of G9SX.

(5) Wiring

1) For model G9SX-SM

Use the following to wire to G9SX-SM

.

-Solid wire: 0.2 to 2.5mm

2

AWG24 to AWG12

-Stranded wire (Flexible wire): 0.2 to 2.5mm

2

AWG24 to AWG12

Strip the cover of wire no longer than 7mm.

2) For model G9SX-SM

-RT (with screw terminals)

Tighten each screw with a specified torque of 0.5 to 0.6N

m, or

the G9SX-SM

may malfunction or generate heat.

(6) Use cables with length less than 100m to connect to standstill

detection Inputs and EDM input respectively.

(7)

Driving voltage of the motor is impressed to the standstill detection

input and there is a possibility that a high level of noise is

superimposed. The line of the standstill input must be separately

installed from other signal lines.

(8)

Set the time duration of Standstill detection time to an appropriate

value that does not cause the loss of safety function of system.

(9)

Tuning mode in User configuration is only for adjusting the Standstill

determining time. In Tuning mode, auxiliary monitor output is enable

however Safety Standstill detection outputs are not enabled. After

the tuning is complete, be sure to change from Tuning mode to

Monitoring mode for actual operation.

(10)

Safety standstill detection outputs are only for controlling a guard

lock safety-door switch with mechanical lock. They can not be

used as safety outputs to drive contactors, or to control a guard

lock safety-door switch with solenoid lock.

(11) To determine safety distance to hazards, take into account the

delay of safety standstill detection outputs caused by the response

time.

(12) Start entire system after more than 5s have passed since applying

supply voltage to all G9SXs in the system.

(13) G9SX-SM

may malfunction due to electro-magnetic disturbances.

Be sure to connect the terminal A2 to ground.

(14) This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take

adequate measures to reduce interference.

(15) Devices connected to G9SX-SM

may operate unexpectedly.

When replacing G9SX-SM

, disconnect it from power supply.

(16) Adhesion of solvent such as alcohol, thinner, trichloroethane or

gasoline on the product should be avoided. Such solvents make

the marking on G9SX-SM

illegible and cause deterioration of

parts.

(17) Connectable motor

AC induction motors can be connected to the G9SX-SM

. Servo

motors cannot be connected.

When a motor with AC240V or more is used,connect neutral point

of the power supply to earth.

(18) G9SX-SM

does not have motor fault detective function or motor

protective function. For motor protection, use designated external

protective devices.

(19) For use with inverter

The dynamic break setting time should be set to 30 seconds or

shorter. Otherwise, the G9SX-SM

may detect a disconnect fault

of the wiring.

Also in the following cases, the standstill detection function may

not properly work even while the motor is in standstill.

1. An inverter with a large output residual voltage is used, and the

contactor connected in serial with the inverter is in the ON state.

2. The inverter is executing the auto tuning function.

(20) Operate the reset input more than 0.4 seconds immediately after

the safety outputs are OFF.

G9SX-SM

does not accept the reset input from when the

outputs are turned ON and until 0.4 seconds passes after the

outputs are turned OFF.

Precautions for Correct Use

(1) Handle with care

Do not drop G9SX-SM

to the ground or expose to excessive

vibration or mechanical shocks. G9SX-SM

may be damaged and

may not function properly.

(2) Conditions of storage and usage

Do not store or use in such conditions stated below.

1) In direct sunlight

2) At ambient temperatures out of the range of -10 to 55

°

C

3) At relative humidity out of the range of 25% to 85% or under

such temperature change that causes condensation.

4) In corrosive or combustible gases

5) With vibration or mechanical shocks out of the rated values.

6) Under splashing of water, oil, chemicals

7) In the atmosphere containing dust, saline or metal powder.

G9SX-SM

may be damaged and may not function properly.

(3) Mounting

Mount G9SX to DIN rails with attachments (TYPE PFP-M, not

incorporated to this product), not to drop out of rails by vibration etc.

especially when the length of DIN railing is short compared to the

widths of G9SX.

Do not use G9SX-SM

at altitudes over 1,000 meters.

- 2 -

25mm min

25mm min

50mm min

50mm min

G9SX-NS202

24VDC

G9SX-SM032

24VDC

No.

AND

NS

FB

ERR

EI

PWB

D4

L1

S24

S14

A2

X2

T42

T41

A1

X1

D2

D1

D3

T32 T33

T31

No.

OFF-DELAY

0.5

0.4

0.3

0.2

3.0

2.5

2.0

1.8

1.4

1.2

1.0

0.9

0.8

0.6

0.7

0

L1

S54

S44

S24

S14

D4

A2

T42

T41

T22

T21

A1

X2

X1

D3

D2

D1

Y1

T12

T11

T33

T31

T1

ERR

EI

AND

FB

ED

T2

NS

PWR

T32

G9SX-NSA222-T03

24VDC

PWR

EDM

CH1

CH2

ES

ERR

SET