8 |

P a g e

4

SYNC Configuration

Layer N Smart Probe products are easily configurable through SYNC configuration software. Ensure SYNC is running on your

Windows OS computer before continuing. Connect your SP-010 to your computer through your Layer N Smart Interface.

Note:

SYNC is available to download for free on the OMEGA website.

4.1

Connecting to SYNC - Automatic Detect

Once the SP-010 and Layer N Smart Interface are connected to your computer, SYNC will automatically detect it and begin

displaying readings.

Note:

If you have successfully connected your SP-010 to SYNC and have readings appearing in SYNC, skip ahead to

the section titled Load Cell Interface.

4.2

Connecting to SYNC – Manual

If SYNC does not automatically detect your device, follow these instructions to manually connect it.

Step 1:

Click on the

icon located on the top left of the SYNC interface.

Step 2:

Proceed through the Add Device Wizard and click

End Device / Probe

.

4.2.1

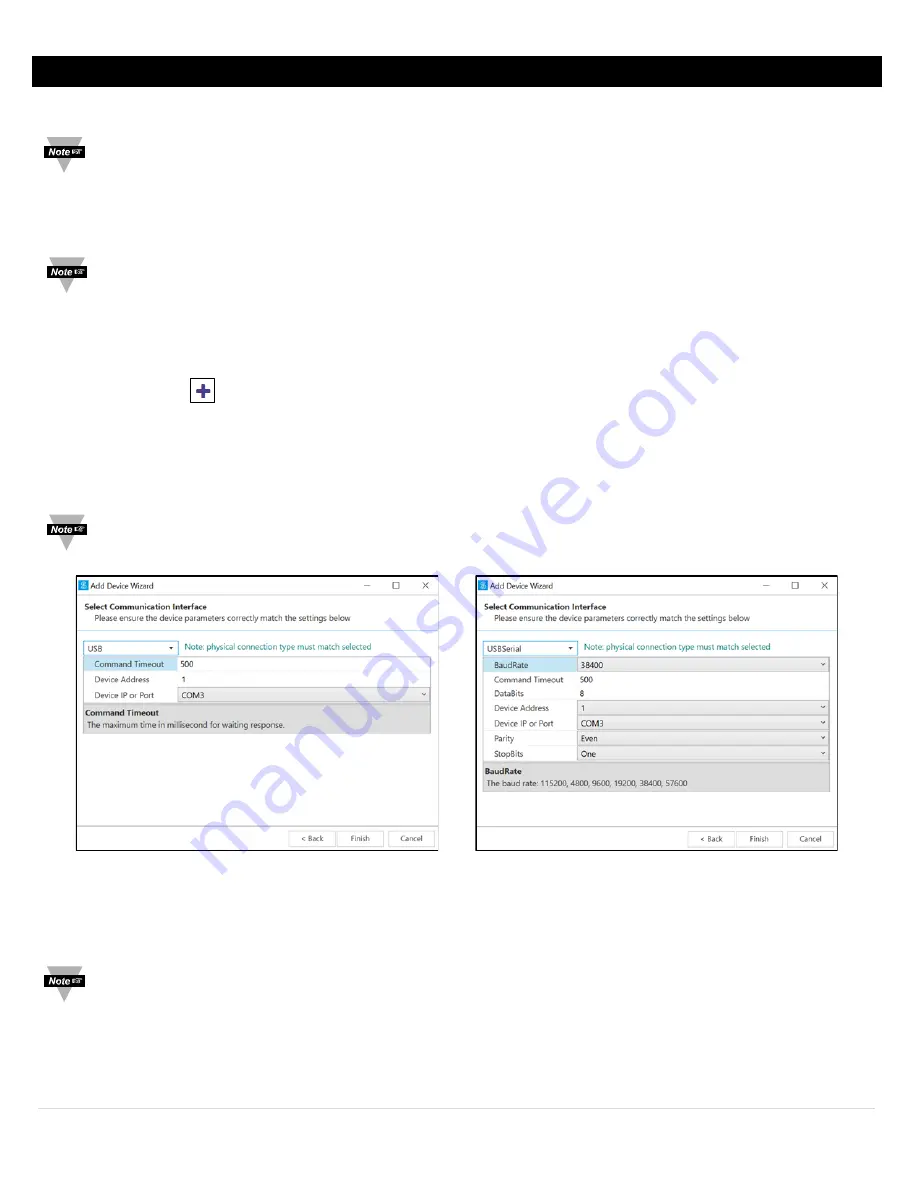

Communication Interface

Set the communication parameters for the Layer N Smart Interface that you are connecting.

Note:

The connection type and parameters must be accurate for a proper connection to be established. Failure to

accurately setup communication parameters may result in communication errors.

•

Connection Type:

Select the type of connection you have between your SP-010 and your computer.

•

Command Timeout:

The maximum time (in milliseconds) for a command to be completed before the command is

aborted.

Note:

The default command timeout is 500 milliseconds. It is recommended that this section be left alone to avoid

communication errors.

USB Communication Interface

USB Serial Communication Interface