10

Officine Gullo

INDEX

GAS TECHNICAL DATA TABLE ................................................................ 11

ELECTRIC TECHNICAL DATA TABLE ................................................... 11

DECLARATION OF COMPLIANCE .......................................................... 12

INSTALLATION ............................................................................................ 12

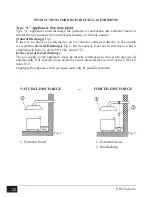

CHECKING FOR ADEQUATE VENTILATION ....................................... 12

PIPE FOR GAS CONNECTION .................................................................. 13

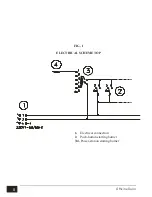

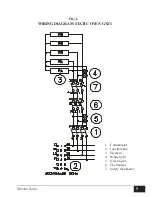

ELECTRIC CONNECTION ......................................................................... 13

EQUIPOTENTIAL ......................................................................................... 14

CHECKING HEAT OUTPUT ....................................................................... 14

CHECKING PRIMARY AIR TO THE MAIN BURNERS AND PILOT

NOZZLES ........................................................................................................ 14

“BURNER” TECHNICAL DATA TABLE ................................................... 15

RULES FOR CONVERTING AND INSTALLING

OTHER TYPES OF GAS ............................................................................... 16

CHANGING THE OPEN RING NOZZLES ............................................... 16

SUBSTITUTING THE NOZZLE IN THE OVEN BURNER .................... 16

SUBSTITUTING THE NOZZLE IN THE COUP DE FEU BURNER ..... 16

CHECKING FUNCTIONING ...................................................................... 17

MAINTENANCE ............................................................................................ 17

SPARE PARTS ................................................................................................ 17

INSTRUCTIONS FOR USE .......................................................................... 18

CLEANING AND MAINTENANCE ............................................................ 20

WHAT TO DO IN THE EVENT OF A BREAKDOWN ............................. 21

PROCEDURE TO FOLLOW IF THE APPLIANCE IS NOT .................. 21

GOING TO BE USED FOR SOME TIME .................................................. 21

MAINTENANCE (only for qualified personnel)

......................................... 21

INSTRUCTIONS FOR DISCHARGING GAS EMISSIONS .................... 22

Содержание GGS8P

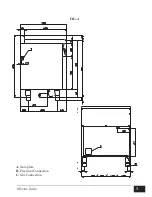

Страница 3: ...3 Officine Gullo A Data plate B Electrical Connection C Gas Connection FIG A...

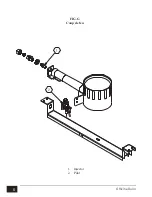

Страница 6: ...6 Officine Gullo FIG G Coup de feu 1 Injector 2 Pilot...

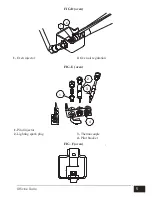

Страница 7: ...7 Officine Gullo 5 FIG K FIG H...

Страница 23: ...23 Officine Gullo...