Officine Gullo

10

DECLARATION OF COMPLIANCE

This appliance is manufactured by OFFICINE GULLO S.r.l

Headquarters and factory

Via Della Torricella 29, Antella, Bagno a Ripoli

50012 Florence - Italy

Tel. +39 055 65 60 3324

+39 055 62 18 07

officinegullo.com | [email protected]

The manufacturer declines any responsibility for direct or indirect damage caused by improper or incorrect

installation, alterations, maintenance or use of the appliance, as in all the other cases considered in the items of our

sales conditions.

WATER SUPPLY CHARACTERISTICS

The system must be connected to a drinking water supply with the following characteristics. Failure to do so

automatically

invalidates the guarantee.

•

Total hardness: 0,5 to 5°F to prevent the build-up of lime-scale

•

Pressure: 50 to 250 kPa (0,5-2,5 bar).

•

Chlorine ion concentration (Cl-): not more than 10 ppm (acceptable value) to avoid damaging the internal

steel elements

•

pH: over 7

•

Electrical conductivity: 50 to 2000 μS/cm (20°C)

INSTRUCTIONS FOR INSTALLATION

The data plate is on the side (see diagram in electric connection item) and has all the data necessary for the

connection.

LAWS, TECHNICAL RULES AND NORMS

Installation must be carried out observing the following norms:

- Safety prescription in force

- Installation prescription in force

11

Officine Gullo

INSTALLATION

When fitting, the appliance must be levelled using a spirit level; slight differences of level can be adjusted by screwing

or unscrewing the adjustable feet. The main switch or the socket must be near the appliance and easily accessible. It is

advisable to place the appliance under an extractor hood so that steam is extracted rapidly. If the appliance is placed

near walls, dividing panels, kitchen furniture, decorative finishing, etc. , these should be in flameproof material; otherwise

it is necessary to cover them with non-flammable material.

Above all, it is necessary to ensure that the fire prevention norms are observed.

The installation, starting up and maintenance of the appliance must be carried out by qualified personnel. All operations

done when installing must be carried out observing the norms in force.

The manufacturer declines all responsibility in the event of incorrect functioning due to wrong installation or installation

which does not comply with the norms.

Attention!

In accordance with international rules, when connecting the appliance, an automatic device enabling the

disconnection of all contacts from the mains, must be installed above it, this device must have a contacts opening of at

least 3 mm.

TECHNICAL ELECTRICAL DATA TABLE

MODELS

DIMENSIONS

cm

POWER SUPPLY

Power max

kW

Absorbition

max A

Power supply

cable (Silicon)

CVS4E

40 x 70 x 29h

400Vac3N 50/60 Hz

5

7,25

5 x 1 mm²

CVCS4E

40 x 70 x 90h

400Vac3N 50/60 Hz

7,8

11,3

5 x 1,5 mm²

CVS6E

60 x 70 x 29h

400Vac3N 50/60 Hz

7,5

10,87

5 x 1,5 mm²

CVCS6E

60 x 70 x 90h

400Vac3N 50/60 Hz

13,5

19,48

5 x 2,5 mm²

TRANSFORMATION

MODELS

DIMENSIONS

cm

POWER SUPPLY

Power max

kW

Absorbition

max A

Power supply

cable (Silicon)

CVS4E

40 x 70 x 29h

230Vac3N 50/60 Hz

5

21,74

3 x 2,5 mm²

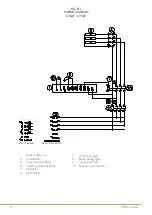

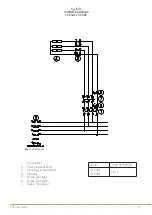

ELECTRIC CONNECTION

The appliance is supplied without the connection cable.

To install the power supply cable, proceed as follows:

•

Disconnect the power supply.

•

Remove the bottom panel.

•

Push the connection cable through the cable blocker, connect the conductor wires to the corresponding terminals in

the junction box and fix them into place.

•

Block the cable with the cable blocker, and reassemble the front panel. The earth wire must be longer than the others

so that if the cable blocker should break, it will disconnect after the tension wires.

N.B.

The connection cable must have an adequate section for the power of the appliance and be resistant to a temperature

of at least 150°C (see technical data table).