12

Officine Gullo

ELECTRIC CONNECTION (mod. CVC...)

The appliance is supplied without the connection cable.

To install the power supply cable, proceed as follows:

•

Disconnect the power supply.

•

Remove the bottom panel.

•

Push the connection cable through the cable blocker, connect the conductor wires to the

corresponding terminals in the junction box and fix them into place.

•

Block the cable with the cable blocker, and reassemble the front panel. The earth wire must

be longer than the others so that if the cable blocker should break, it will disconnect after

the tension wires.

N.B.

The connection cable must have an adequate section for the power of the appliance and be

resistant to a temperature of at least 150°C (see technical data table).

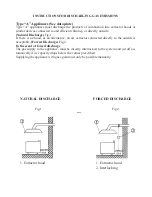

EQUIPOTENTIAL

The appliance must be connected to an equipotential system. The connection screw is positioned

at the back of the appliance and is identified by the symbol

.

Attention:

The manufacturer will neither be held responsible for, nor will give any compensation

during the guarantee period for any damage caused, and which is due to inadequate installations

not compliant with the instructions.

CHECKING HEAT OUTPUT

The appliances must be checked in such a way as to verify that the heat output is correct:

•

The heat output (thermal power) is indicated on the data plate of the appliance.

•

Firstly, check that the appliance can be used with the type of gas supplied; then

check that the indication on the plate corresponds to the gas to be used. For con-

verting to another type of gas, check that the type of gas complies with what is

stated in this instruction manual.

The pressure is read with a gauge (minimum resolution of 0.1 mbar) inserted in the relative

pressure outlet.

Remove the hermetically closed screw and connect the gauge pipe.

After reading, put back the screw, tightening it hermetically and check for leaks.

Connection for liquid gas G30/G31

The connection pressure for liquid gas is 30 mbar with butane and 37 mbar with propane.

Check the plate, read the pressure and verify that the description of the nozzle installed

corresponds to the one supplied by the manufacturer.

Connection with natural gas H G20

The connection pressure for natural gas is 20 mbar.

Check the plate, read the pressure and verify that the description of the nozzle installed

corresponds to the one supplied by the manufacturer.

Содержание CVCS4G

Страница 7: ...7 Officine Gullo FIG E WATER FILLING TAP...

Страница 21: ......

Страница 22: ......

Страница 23: ......