BA_OLW I OTE3_SW5x_EN_20160815_V2

18 / 48

9 Commissioning

Commissioning must be carried out by Ochsner Cus-

tomer Service or a service partner authorised by

Ochsner. The Ochsner commissioning guidelines must

be adhered to. Operating the system without a correct

commissioning will lead to a forfeiture of the guarantee

and warranty rights.

9.1

Required on-site personnel

Electrician, installer and future system supervisor

MUST

be present for the system orientation during

commissioning.

INSTRUCTIONS for the system installer.

•

The OCHSNER Customer Service engineer /

Customer Service partner will execute the user-

specific settings

according to the specifications

in the system data sheet.

•

Should the system installer not be present during

commissioning, or if there is no fully completed

system data sheet present, the system will be

commissioned using the control's factory settings.

•

OCHSNER accepts no liability for possible mal-

functioning (heating curve too low, bivalent point

too high, etc.). Any claims resulting from this will

be invoiced to the system installer.

•

In order to run the system economically,

it is absolutely necessary that the system be bal-

anced hydraulically and that the control settings

are coordinated to the system requirements.

•

Other necessary work performed, such as bleed-

ing the system, electrical wiring, additional instruc-

tion etc., that do not fall within the realm of the

OCHSNER firm’s duties will be invoiced separate-

ly

9.2 Non-self-resetting safety thermostat

At outside temperatures below - 15 °C, the non-self-

resetting safety thermostat can trigger the electric

emergency/auxiliary heater. Check whether the safety

thermostat has been activated.

Reset the safety thermostat by pressing the reset

button.

1 safety thermostat reset button

2 electric emergency/auxiliary heater

Fig.25: Non-self-resetting safety thermostat

9.3 Appliance function

Electric emergency/auxiliary heater in the heat pump

flow:

•

Mono-energetic operation

The electric emergency/auxiliary heater guaran-

tees the heating operation as well as higher water

temperatures if the outside temperature falls be-

low the bivalent point.

•

Emergency operation

If the heat pump malfunctions, the heating will be

taken over by the electric emergency/auxiliary

heater.

•

Heat-up

program

(underfloor heating only)

For return temperatures <25 °C, the electric emergen-

cy/auxiliary heater must take over the drying out of the

flooring screed!

The drying out cannot be carried out using the heat

pump as the system temperatures are too low and,

during the de-icing cycle the frost protection cannot be

guaranteed.

At the end of the drying out program, the electric

emergency/auxiliary heater can be disconnected if it is

not needed for the normal appliance operation.

Please note that the emergency operation cannot be

activated during the drying out program.

Anti-legionella switching

The electric emergency/auxiliary heater will be auto-

matically switched on if the anti-legionella program is in

place. The water will be regularly heated to 60 °C as

protection against Legionella.

Содержание OLWI 13

Страница 2: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 2 48 ...

Страница 25: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 25 48 14 2 Hydraulic diagram ...

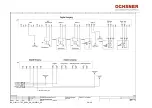

Страница 26: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 26 48 14 3 Electric circuit diagrams OTE ...

Страница 27: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 27 48 ...

Страница 28: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 28 48 ...

Страница 29: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 29 48 14 4 Wiring overview ...

Страница 37: ...BA_OLW A I OTE3_SW5x_DE_20160510_V2 37 48 15 Declaration of Conformity ...

Страница 38: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 38 48 ...

Страница 39: ...BA_OLW A I OTE3_SW5x_DE_20160510_V2 39 48 16 ERP Data ...

Страница 40: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 40 48 ...

Страница 47: ...BA_OLW I OTE3_SW5x_EN_20160815_V2 47 48 ...