2

1

1

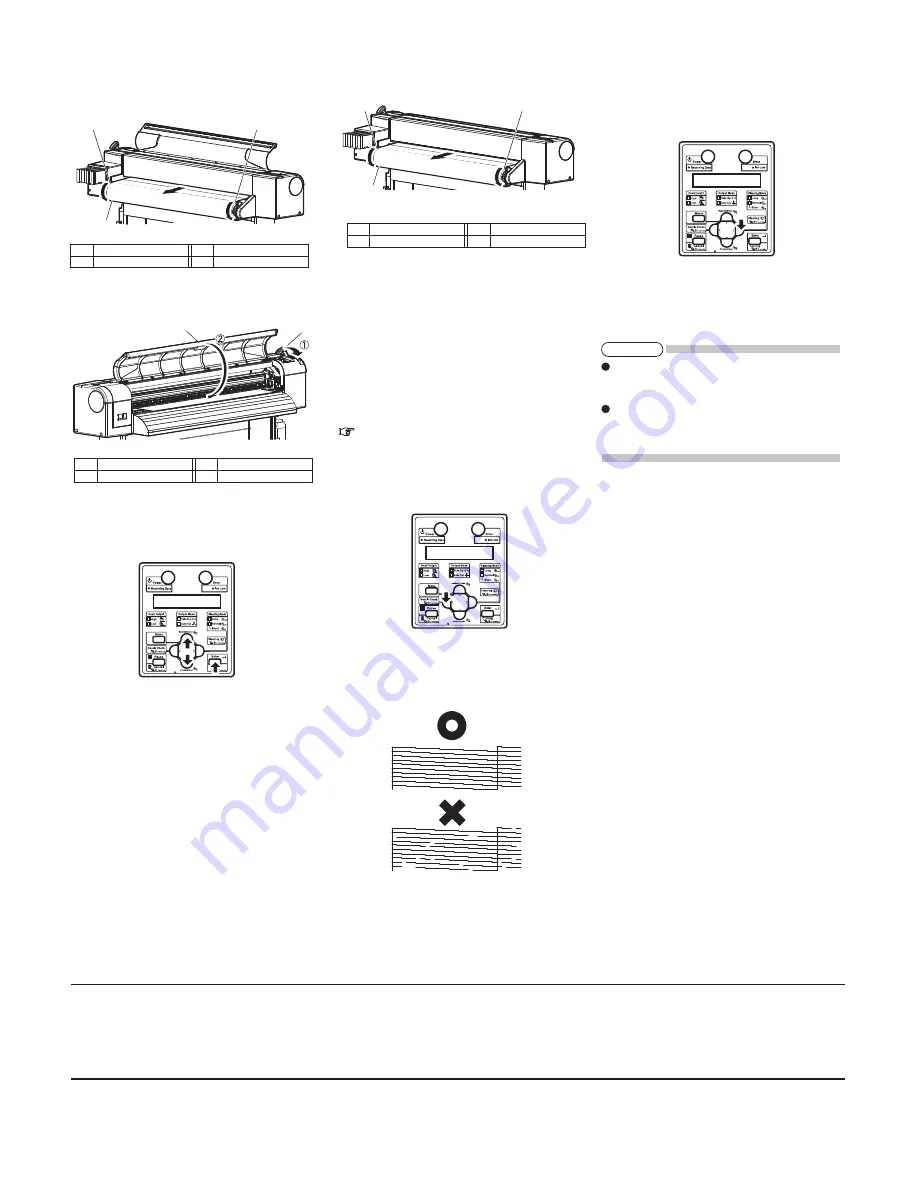

Roll media

2

Scroller

No.

No.

Name

Name

Océ - Technologies B.V.

St. Urbanusweg 43

Venlo, The Netherlands,

P.O. Box 101, NL 5900 MA Venlo

9. Press and hold the front edge of the roll media and

wind it back with the scroller to remove a media bend

or slant.

10. Return the media loading lever to the front and

close the front cover.

11. Press the [+] key or [-] key on the operation panel to

select the type of the loaded media and press the

[Enter] key.

This confirms the media type.

The operation panel displays "Media Initial", and

media initial operation starts.

After the media initial operation is completed, the

operation panel displays "Ready to Print", and the

display enters normal status.

12. Wind back the roll media with the scroller to remove

a media bend.

The media loading is complete.

11 Checking printing conditions

Check the condition of the print head after the ink

replenishment.

1. Turn ON the printer and load the roll media.

8 Loading the roll media

2. Confirm that the printer functions normally.

3. Press the [<] key on the operation panel for two

seconds or more.

Nozzle check printing starts.

4. Check the sample print for blurred or missing

parts in the check pattern.

5. If the nozzle check result indicates that there is a

problem such as mentioned above in the check

pattern, clean the head.

Press and hold the [Cleaning] key on the operation

panel for two seconds or more.

The operation panel displays "Cleaning **%".

Head cleaning starts.

6. Perform nozzle check again and check the

condition of the print head.

7. Perform nozzle check again and check the

condition of the print head.

2

2

1

1

2

2

No.

Name

No.

Name

1

Media loading lever

2

Front cover

No.

Name

No.

Name

1

Roll media

2

Scroller

NOTE

If one time of head cleaning was not enough to

remove blurred or missing parts in the check

pattern, perform powerful cleaning.

If those problems above were not improved after a

few times of head cleaning, refer to the Operation

Manual "7 Troubleshooting" and perform required

procedures.