OBO Bettermann

64 | EN

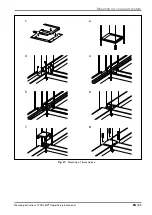

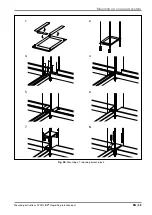

Mounting on a support system

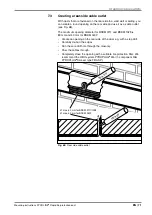

Wall penetration in

dry/lightweight construction wall

(I120):

As the required lifespan is not guaranteed through screwing in in the light-

weight construction wall, use threaded rods instead, which you can push

through the wall and screw tight on both sides.

I30

I60

I90

I120

BSKM 0711/1025

BSKM 0711/1025

5-10 mm

max. 1 m

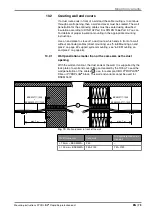

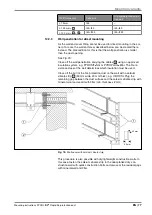

Fig 62:

Wall penetration through dry/lightweight construction wall

Note!

Observe the minimum wall thickness: For I30–I120 min. 100 mm

Note!

An additional crossbar for load bearing in the wall is not required.

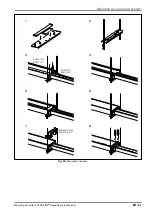

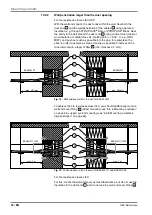

See Fig. 63:

1

Stick the self-adhesive sealing strip to the lock plate.

Drill the holes for the threaded rods.

Fasten the lock plate with the threaded rods, washers and nuts to the

bottom edge of the wall opening at the desired height.

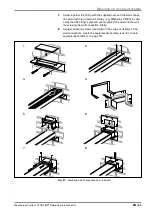

2

Shorten the cables as necessary. If necessary, use locking brackets

for the duct lid (see “4.4 Inserting locking brackets” on page 19).

Insert the duct in the wall, observing the gap width of the onward

duct of 5‒10 mm.

Insert cables.

3

For duct BSKM 1025: insert the lid support (see “4.5 Using lid sup-

port” on page 20) and push it through to the end of the duct (see

“Fig. 15: Inserting lid support” on page 20).

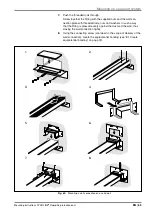

4

Stick the enclosed sealing strip onto the wall connection fitting.

5

Attach the duct lid firmly.

Plug the opening with mineral wool and seal with filler (see “6.2.2

Wall penetration in dry/lightweight construction wall” on page 47).

Attach the wall connection fitting.

6

Attach the wall connection plate.

Drill the holes for the threaded rods.