Nuvair Open Electric Models

Nuvair Page 9

www.Nuvair.com

1.7

Where the Compressor may be used

This high pressure compressor

has been designed and built for the purpose of producing

breathing air by drawing it from the surrounding environment. The surrounding environment air

must be free from any harmful fumes or contaminates. The air is passed through an intake air

filter, compressed and run through breathing air filtration before it is stored in bottles constructed

to contain air at high pressure.

The compressor must only be used in environments having the

characteristics described in the following table.

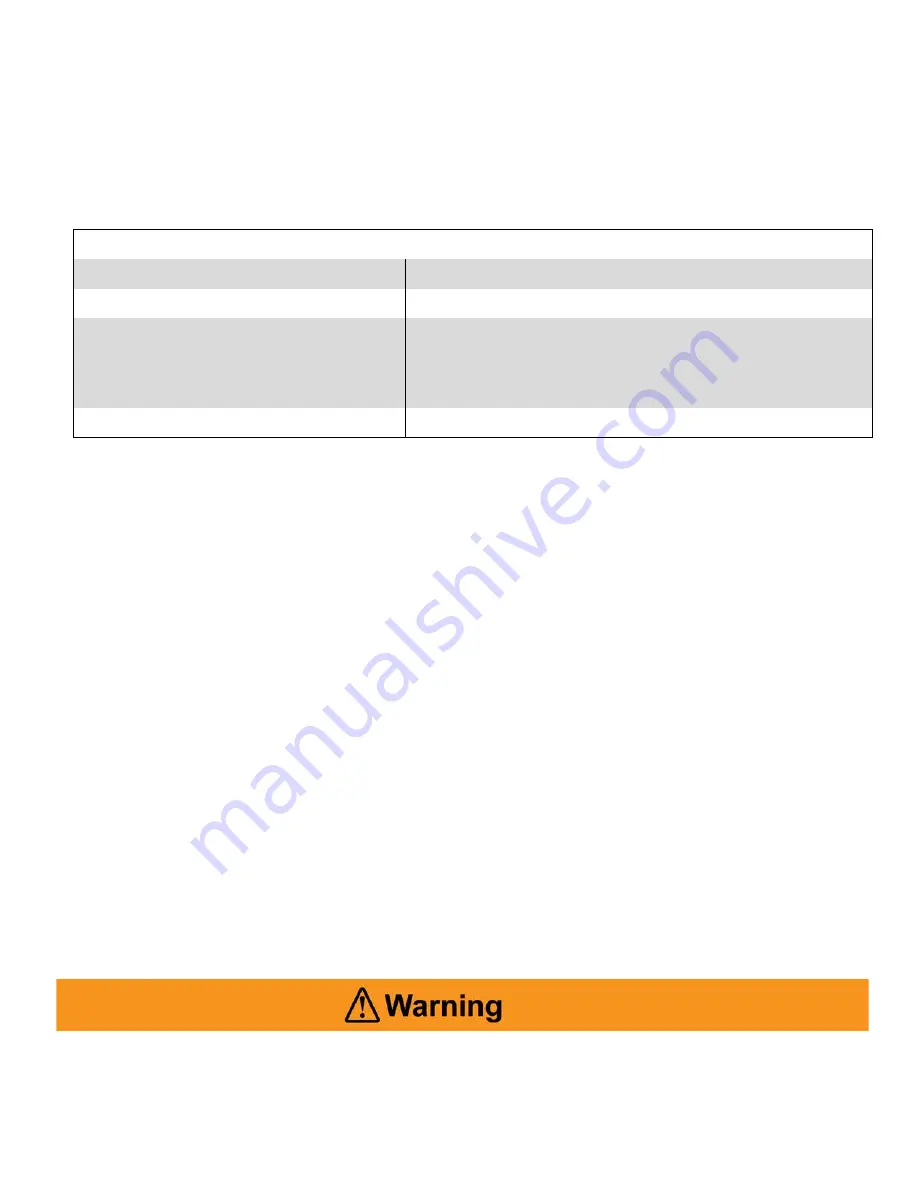

Area of Machine Use: Essential Data Table

Temperature ambient

Min. +41°F - Max. +113°F (Min. +5°C - Max. +45°C)

Air humidity

(%) Maximum 80%

rain

Tolerated Weather Conditions

hail none

snow

Max tilt angle (bank)

(%) 6%

Check that the area in which the compressor is to be positioned is adequately ventilated: good air

exchange (more than one window) with no dust and no risk of explosion, corrosion or fire. If

ambient temperatures exceed 113°F (45°C) air conditioning will be required. Make sure that

lighting in the area is sufficient to identify every detail (such as the writing on the info

plates/stickers); use artificial lighting where daylight on its own is insufficient.

•

When Pumping Nitrox, Ambient temperature Maximum is 100°F and Maximum fill pressure

is 3600 psi.

1.8

Running and Testing the Compressor

Each compressor is carefully ran and tested prior to delivery. A new compressor must

nevertheless be used with caution during the first 5 working hours so as to complete proper

breaking in of its components. If the compressor is subject to an excessive workload during initial

use, its potential efficiency will be prematurely compromised and functionality soon reduced.

During the breaking in period proceed as follows:

•

After starting the unit, let the compressor run un-loaded for 5-6 minutes.

After the first 25 hours carry out in addition to the scheduled maintenance the following tasks:

•

Change the compressor oil

•

Change the oil filter

•

Check and adjust nuts and bolts

When changing the oil filter, inspect the filter element and check for any deposits. If metal or

carbon deposits are present, locate the source before restarting the compressor.