7

22. 04. 21. Document Number 671506

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

BESPOKE BOXER

Installation Manual

3.9 Control Dampers

Care should be taken to ensure that all spring return actuators have

stopped running and completed their stroke. If not, the connection

needs to be loosened and the actuator should be left to drive until the

motor stops running.

When the unit is powered, dampers should be checked to ensure that

they operate freely and close tightly.

3.10 Final Inspection

•

Thoroughly inspect the unit after installation is complete.

•

The inside of the unit should be checked; any objects which may

have been left should be cleared.

•

Check fan impellers, scrolls and outlets.

•

Remove any transit protection fittings that may be attached to the

fan or motor base frame, and that all traps are primed.

•

Close all access door seals for damage, and replace any panels that

have been removed.

4.0 ELECTRICAL INSTALLATION

The electrical wiring must be carried out by competent persons, in

accordance with good industry practice and should conform to all

governing and statutory bodies i.e. IEE, CIBSE etc.

Ensure suitable earth bonding is maintained on all AHU sections.

4.1 Wiring (If Applicable)

4.1.1 AC Motor Fans

Inverter speed control is required for these units and can be provided by

Nuaire as optional extras, any inverters should be configured to match

the design and running frequency that is provided on the datasheet of

each specific fan.

Care should be taken to ensure that the rotation of three phase motors

correspond with the direction shown on the frame.

All electrical connections to the fan are to be made using flexible cable

and containment materials to allow for the movement of anti-vibration

mounts.

12

Typical Fan (AC Motor) Wiring

L1 L2 L3

U1

W1

PE

V1

U2

W2

V2

3 Phase only

Inverter Speed Control

Motor

Terminal

Connections

Inverter Drive

INPUT

OUTPUT

Notes:

Inverters are typically unconfigured, and require configuring

to suit project specific fans and control applictions.

Internal Factory Connection

Mandatory Customer Connection

Key:

U1

W1

V1

400V 3 phase 50Hz supply

Motor

3 Phase

U1

W1

V1

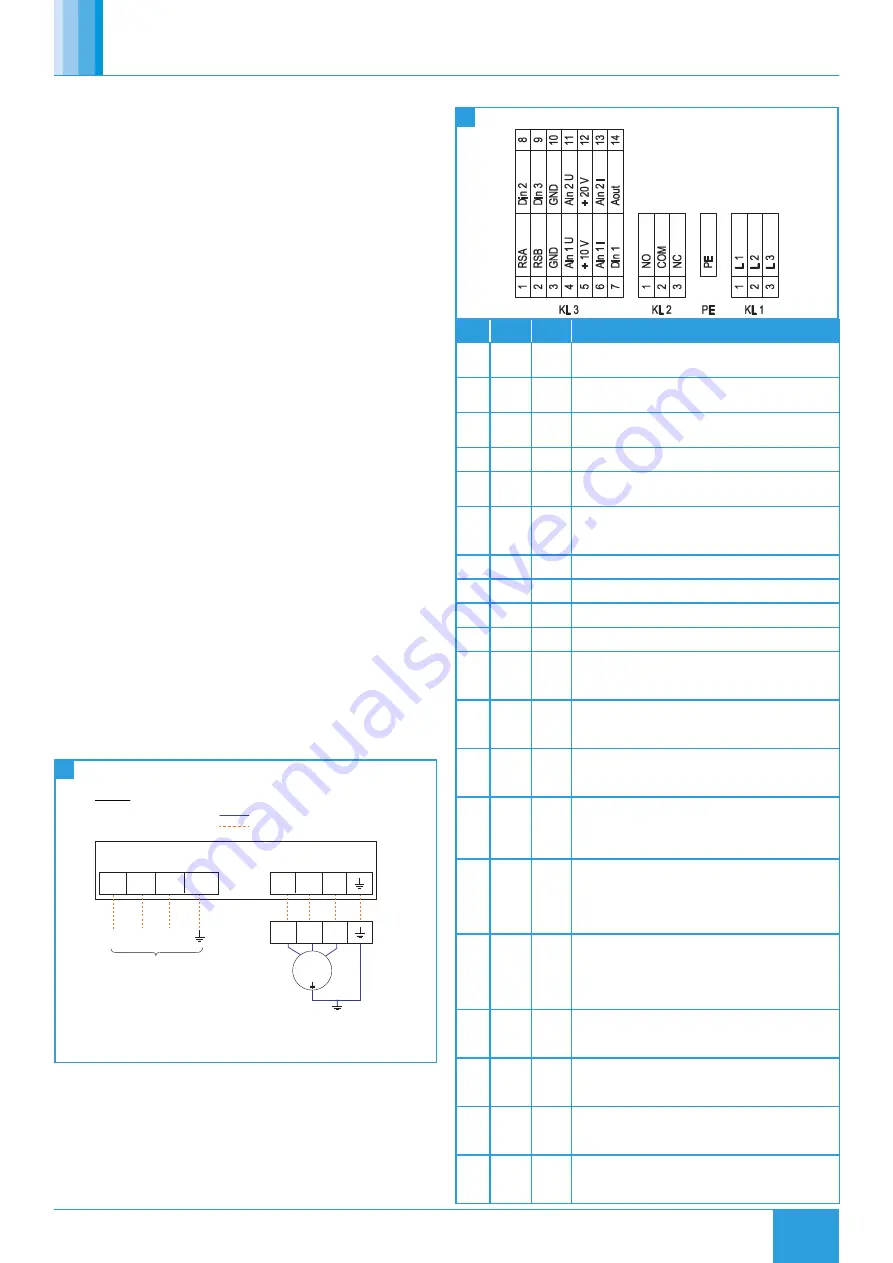

4.1.2 EC Motor Fans

13

Typical Fan (EC Motor) Wiring

No.

Conn.

Desig.

Function / Assignment

KL1

1

L1

Mains supply connection, supply voltage 3~380-480 VAC;

50/60 Hz

KL1

2

L2

Mains supply connection, supply voltage 3~380-480 VAC;

50/60 Hz

KL1

3

L3

Mains supply connection, supply voltage 3~380-480 VAC;

50/60 Hz

PE

PE

Earth connection, PE connection

KL2

1

NO

Status relay, floating status contact; normally open; close

with error

KL2

2

COM

Status relay; floating status contact; changeover contact;

common connection; contact rating 250 VAC / max. 2 A

(AC1) / min. 10 mA

KL2

3

NC

Status relay, floating status contact; break with error

KL3

1

RSA

Bus connection RS-485, RSA, MODBUS RTU; SELV

KL3

2

RSB

Bus connection RS-485, RSA, MODBUS RTU; SELV

KL3

3/10

GND

Signal ground for control interface; SELV

KL3

4

Ain1 U

Analogue input 1, set value: 0-10 V, Ri = 100 kΩ,

parametrisable curve, only usable as alternative to input

Ain1; SELV

KL3

5

+ 10 V

Fixed voltage output 10 VDC, +10 V ±3%, max. 10 mA,

short-circuit-proof, power supply for external devices (e.g.

potentiometer), SELV

KL3

6

Ain1 I

Analogue input 1, set value: 4-20 mA; Ri = 100 Ω,

parametrisable curve, only usable as alternative to input Ain1

U; SELV

KL3

7

Din1

Digital input 1: enabling of electronics, Enabling: open pin

or applied voltage 5-50 VDC. Disabling: bridge to GND or

applied voltage <1 VDC. Reset function: triggers software

reset after a level change to <1 VDC; SELV

KL3

8

Din2

Digital input 2: parameter set switch 1/2, according to

EEPROM setting, the valid/used parameter set can be

selected via bus or via digital input DIN2. Parameter set

1: open pin or applied voltage 5-50 VDC. Parameter set 2:

bridge to GND or applied voltage <1 VDC; SELV

KL3

9

Din3

Digital input 3: controller function of integrated controller,

according to EEPROM setting, the controller function of the

integrated controller is normally/inversely selectable per bus

or per digital input. Normal: open pin or applied voltage 5-50

VDC. Inverse: bridge to GND or applied voltage <1 VDC; SELV

KL3

11

Ain2 U Analogue input 2, actual value: 0-10 V, Ri = 100 kΩ,

parametrisable curve, only usable as alternative to input

Ain2; SELV

KL3

12

+ 20 V

Fixed voltage output 20 VDC, +20 V +25/-10%, max. 50 mA,

short-circuit-proof, power supply for external devices (e.g.

sensors); SELV

KL3

13

Ain2 I

Analogue input 2, actual value: 4-20 mA, Ri = 100 Ω,

parametrisable curve, only usable as alternative to input Ain2

U; SELV

KL3

14

Aout

Analogue output 0-10 VDC, max. 5 mA, output of the current

motor level control coefficient / motor speed parametrisable

curve; SELV