Page 11

NOL Compact Modulating

Check that all relevant documentation is

available including, where appropriate:

The agreed plant performance

specifications.

Plant drawings and pipework layouts.

Electrical logic and wiring diagrams.

Certificates confirming satisfactory

completion of procedures such as

soundness testing and electrical safety

tests.

Commissioning, operating and

maintenance instructions for the plant.

Establish that the operation of plant other

that being commissioned will not have an

adverse effect on the operation of the plant

to be commissioned and similarly, that the

operation of the plant to be commissioned

will not have and adverse effect on other

plant.

Confirm that the operation of adjacent plant

and machinery will not constitute a hazard

to the personnel involved in commissioning.

Pre-firing Checks

With the oil and power switched off, carry out the

following checks.

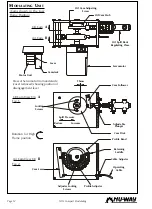

Check the nozzle size and position relative

to the diffuser plate. (The burner head

dimensional details are given on page 20).

Check that the electrode positions and H.T.

leads are correct.

Check the fan motor overload settings.

If the appliance is a boiler, check that the

water level is correct, the controlling valves

are open and that the water pumps are in

working order.

If a flue damper is fitted, check that it is

correctly interlocked to the burner or fixed

in the fully open position.

Ensure that there is a good oil supply to the

burner pump. Bleed one or two gallons from

the flexible to eliminate any pipe scale and

air from the system.

Check that the oil supply is of the

recommended temperature and pressure.

Bleed the burner pump manually by

removing the right hand ¼ BSP plug in the

top of the pump until air free oil flows.

Switch on the electricity supply to the burner.

Remove the access lid on the modulating

cam box unit.

Switch on the burner at the control panel.

The modulating unit camshaft should now

rotate to the high flame setting, and the

combustion air motor will start the air pre

purge phase.

Allow the fan motor to run up to speed,

switch off the burner and check the fan

rotation (Anti clockwise as viewed from the

motor side) as the fan slows down.

Remove and cover the photoelectric cell with

a clean lint free cloth, switch on the burner,

and allow it to run through to lockout.

During this run check that the ignition spark

is occurring, and note the spill and line oil

pressures at the moment of ignition. Reset

the sequence control and repeat the run if

necessary to check these functions. If

necessary, adjust the spill pressure to the

correct figure according to the nozzle

specification and the line pressure at the

burner pump to 27.8 bar (400 psi).

THE BURNER IS NOW READY TO BE

COMMISSIONED.

Manual Operation

Check that the RWF40 controller is configured

correctly (refer to page 17). Press and hold the EXIT

key until the manual operation indicator

illuminates. The modulating motor can now be

inched using the increase & reduce buttons on

the controller face. Press and hold the EXIT key

until the manual operation indicator extinguishes

to return to automatic mode

Commissioning the Burner

New burners are generally supplied against the

firing specification of the appliance. In this case the

system and spill pressures may be pre set and

require checking and minor adjustments only. The

following section describes how to set up the

modulating cam box unit from a scratch situation.

The modulating cam layshaft can be rotated by

hand by using the gearbox disengagement lever in

the drive servomotor.

Ensuring that the modulating cam

arrangement is in the low flame position,

adjust the oil cam (see fig. 1 on page 12) so

that it gives approximately 1.5mm throw

(3mm stroke) and lock in position.

Check to ensure that the spill valve push rod

bears lightly against the oil cam.