NOL Compact Modulating

Page 10

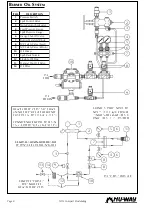

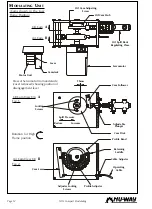

The volume of air required for combustion must

also be varied as the nozzle output varies, and this

is done by the air control damper operated by a

flexible steel cable connected to a lever system

bearing against the air control cam.

Once the oil cam has been adjusted as described

in the

commissioning

section of this handbook, the

profile of the air cam must be adjusted to give the

required combustion conditions. This is achieved

by turning the thumbscrews under the cam in or

out as the burner is inched through its firing range.

The air control damper is spring loaded open for

safety in the event of cable failure.

O

PERATION

When the boiler control calls for heat, the burner

modulating unit will travel to the high flame

position and interlock the control circuit. An air

pre purge will take place at this position for a pre

determined period, at the end of which the burner

sequence controller will stop until the modulating

unit has travelled to the low flame position and

interlocked the control circuit again. The sequence

control will now recommence its operational cycle

and the burner will light and remain at low flame

until the high flame release signal is given by the

sequence control.

Under the instruction of the modulating controller,

the modulating unit will now move to high flame

and remain at this position until the desired boiler

temperature/pressure is attained. From this stage,

the modulating controller will drive the burner

towards the low flame position, but, depending

on the temperature/pressure, will stop in any

intermediate position between low and high

flame.

C

OMMISSIONING

I

MPORTANT

- S

AFETY

It is essential that commissioning shall be

undertaken only by suitably qualified and

experienced personnel. In the case of NOL

Modulating burners, commissioning engineers

should be experienced in pressure jet oil burner

commissioning. Nu way can accept no

responsibility for consequential loss, damage or

personal injury which results from a failure to follow

the commissioning instructions provided or from

commissioning procedures being undertaken by

unqualified personnel.

E

MERGENCY

I

NSTRUCTIONS

NOL Modulating burners are designed and

constructed to meet current legislation. When used

in accordance with the instructions provided, NOL

Modulating burners are unlikely to produce a

hazardous condition. If, however such a condition

should arise in connection with the burner, the

appliance or of any instrument, machine or service

in the vicinity of the burner, the

OIL AND

ELECTRICITY SUPPLIES

SHALL BE ISOLATED

IMMEDIATELY

and they shall remain isolated until

the fault has been identified and rectified.

Inspection

Before commissioning is begun it is important to:

Check that the electrical wiring is complete

and complies with all applicable Codes and

Standards.

Ensure that the fuses are fitted and are of the

correct rating.

Check electrical earthing.

Verify that the oil supply system is correctly

designed and that the supply pipework is

correctly sized and free from leaks.

Ensure that all manual fuel isolation valves

are operable, fully closed and leak tight.

Make all personnel involved in the

commissioning aware of the location of the

emergency fuel and electricity isolation

points.

Check that fittings for bleed and pressure

testing are fitted.

Establish that the appliance is in an

appropriate and safe condition to be fired;

for example, that there is water in the boiler.

Set the appliance controls to call for heat.

Check the appliances ventilation and flueing

arrangements.

Ensure that any warning notices appropriate

to the commissioning procedure are in

position.

Ensure that all necessary tools and test

equipment are available and ready for use.

Essential items include temperature

measuring instruments for measuring flue gas

and appliance water temperatures, and a

means of analysing the flue products for

carbon dioxide (CO

2

), oxygen (O

2

), carbon

monoxide (CO) and smoke.