NOL Compact Modulating

Page 16

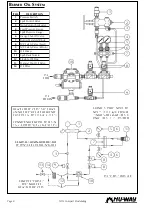

Control Program Under Fault Conditions

And Lockout Indication

In the event of fault conditions the sequence

switch stops and simultaneously the lockout indi

cator. The symbol appearing above the reading

mark indicates the kind of fault encountered.

No start,

because, e.g., the CLOSE signal has

not been supplied to control box terminal 8

by the servo motor limit or auxillary switch,

or a contact has not been closed between

control box terminals 12 and 4 or 4 and 5.

Shut down of start up sequence,

because

the OPEN signal has not been supplied to

control box terminal 8 by the servo motor

limit switch. Terminals 6,7 and 15 remain

under voltage until the fault is corrected.

Lockout

due to a fault in the flame supervi

sion circuit.

Shut down of start up sequence,

because

the signal for the low flame position has not

been supplied to control box terminal 8 by

the servo motor auxillary switch. Terminals

6,7 and 15 remain under voltage until the

fault is corrected.

Lockout,

because no flame signal has been

received on completion of the safety time.

Lockout,

because the flame signal has been

lost during burner operation or an air pres

sure failure has occured.

Lockout on completion or after completion

of the control program sequence

due to ex

traneous light (e.g. flame not extinguished,

leaking fuel valves) or due to a faulty flame

signal (e.g. fault in the flame supervision cir

cuit or similar).

a - b

Start up sequence.

b - b

idle steps up to the self shut down of

the sequence switch.

b(b) - a

Post purge sequence.

When lockout occurs, the control can be reset

immediately. After the resetting (and also after the

correction of a fault which resulted in a controlled

shut down, or after each mains failure) the se

quence switch always runs through to the start

position, whereby

only

terminals 7,9,10 and 11

receive voltage in accordance with the control pro

gram. It is only then that the control unit programs

a fresh burner start up.

Note:

Do not press the lockout reset button (or

remote reset switch) for more than 10 seconds.

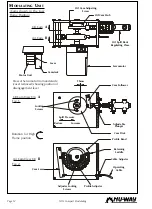

RWF40 M

ODULATING

C

ONTROL

Basic display

The diagram below opposite shows the RWF40

after switching on the supply voltage. This

condition is called the basic display. The actual

operating value and the currently active set point

will be shown. Manual operation, self

optimization, the operating parameter and the

configuration levels can be activated from this

display.

To change the working set point.

The basic display shows the actual pressure/

temperature of the boiler in red and the required

set point pressure/temperature beneath in smaller

green digits.

One quick press of the PGM button, the display

changes to show the set point as the larger red

digits and the SPI in the lower small green digits.

Alter the red display using the up/down buttons

to show the new required set point, press exit or

let the unit time out to return to the basic display

which should be the new set point figure.

To enter a new parameter

The parameters dictate the way in which the burner

firing rate alters in response to changes in the

pressure/temperature of the boiler.

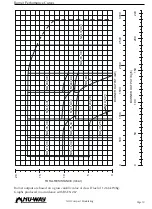

A major factor that determines the need to change

the parameters is if the burner is fitted to a steam

or hot water boiler. The table below indicates the

parameter and its setting for steam and hot water

boilers. It must be emphasised that it is only an

indication and any departure from these settings

should be made in small increments, with time

given to see how the burner is reacting to the

changed parameter.

1

a

b

b

1

Landis & Staefa

LAL1. Program

Sequence Disk.

I