Page 12 of 32

© Brüel & Kjær Vibro

● C104958.002 / V04

Technical alterations reserved!

EN

4

Installation

Read the safety information in the chapter "Safety" before installation. To assemble the displacement

sensor system, proceed in the following order:

•

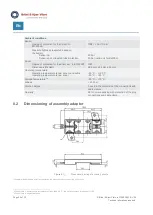

4.1 Assembling the displacement sensor

•

4.2 Assembling the driver (oscillator/demodulator)

•

4.3 Connect the components together

•

4.4 Setting up the measuring chain and the displacement sensor

•

Requirements:

•

The displacement sensor system is complete (se

e “Table 3-1) Components included in scope

•

The overall length of the measuring system neither exceeds nor falls below the nominal length.

•

The required clearances and the width of the measuring track are considered

(8.3.2 Properties of the measuring track und 8.3.3 Required clearances and minimum

distances for displacement sensors)

•

Required clearances and minimum distances for displacement sensors.

•

The sensitivity of the target material is known.

Recommended accessories for trouble-free operation:

•

Install the driver in a housing/control cabinet. For this purpose, the protective driver housings

AC-2126 for up to 3 drivers and AC-2127 for up to 6 drivers are recommended.

•

Use shielded signal wiring (preferably AC-1112) between the driver and connected electronics.

The connection cable has to be heat-resistant at least + 85 °C.

•

Install the sensor cable between machine housing and driver housing in a protective steel

conduit.

•

Install the sensor cable between machine housing and driver housing in a protective steel

conduit.