N1040 Controller

NOVUS AUTOMATION

4/7

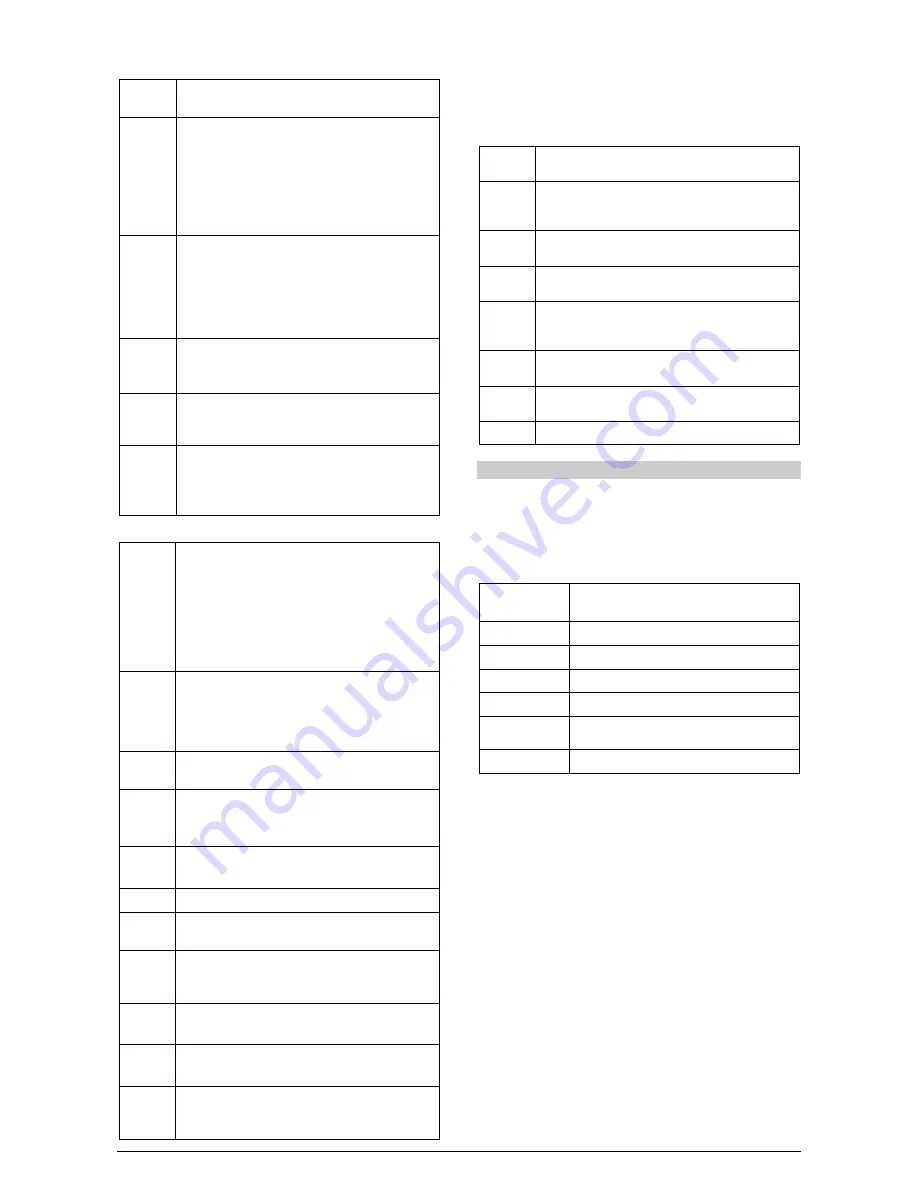

ALARMS CYCLE

Fva1

Fva2

Functions of Alarms. Defines the functions for the

alarms among the options of the Table 02.

Sp.a1

Sp.a2

Alarm SP. Value that defines the point of activation of

the alarm outputs.

For the alarms programmed with the functions of the

type Differential, these parameters represent the

deviations.

For the

ierr

alarm function, this parameter has no

meaning.

Sp1.e

sp2.e

SP Enable. Configures display of SPA1 and SPA2

also in the Operation Cycle.

YES

SPA1/SPA2 are displayed in the Operation

Cycle

NO

SPA1/SPA2 are not displayed in the

Operation Cycle

bla1

bla2

Blocking Alarms.

YES

- Enables initial blocking;

NO

- Inhibits initial blocking.

xya1

xya2

Alarm Hysteresis. Defines the difference between the

value of PV at which the alarm is triggered and the

value at which it is turned off.

flsh

Allows visual signalization of an alarm occurrence by

flashing the indication of PV in the operation level.

YES

- Enables alarm signaling flashing PV;

NO

- Disables alarm signaling flashing PV.

INPUT CYCLE

Type

Input Type. Selects the input signal type to be

connected to the process variable input. Refer to

Table 01 for the available options.

(J):

Tc

J

-110 to 950 °C / -166 to 1742 °F

(K):

Tc

k

-150 to 1370 °C / -238 to 2498 °F

(T):

Tc

t

-160 to 400 °C / -256 to 752 °F

(Pt100):

Pt

-200 to 850 °C / -328 to 1562 °F

fltr

Digital Input Filter. Used to improve the stability of the

measured signal (PV). Adjustable between 0 and 20.

In 0 (zero) it means filter turned off and 20 means

maximum filter. The higher the filter value, the slower

is the response of the measured value.

Dp.po

Selects the decimal point position to be viewed in both

PV and SP.

vn

i

t

Selects display indication for degrees Celsius or

Fahrenheit:

(

- Indication in Celsius;

f

- Indication in Fahrenheit.

0ffs

Offset value to be added to the PV reading to

compensate sensor error. Default value: Zero.

Spll

SP Low Limit. Defines the SP lower limit of.

Spxl

SP High Limit. Defines the upper limit for adjustment

of SP.

Lbd.t

Loop Break Detection Time. Time interval for the LBD

function. Defines the maximum interval of time for the

PV to react to a control command. In minutes.

1e.ov

Percentage value to be applied to the output on any failure

of the sensor that is connected to the controller input.

bavd

Digital communication Baud Rate selection. In kbps.

1.2, 2.4, 4.8, 9.6, 19.2, 38.4, 57.6 and 115.2.

Addr

Communication Address. Number that identifies the

controller in the serial communication network,

between 1 and 247.

CALIBRATION CYCLE

All types of input are calibrated in the factory. In case a

recalibration is required; it shall be carried out by a specialized

professional. In case this cycle is accidentally accessed, do not

perform alteration in its parameters.

pass

Password

.

This parameter is presented before the

protected cycles. See item Protection of Configuration.

(alib

Calibration

.

Enables the possibility for calibration of

the indicator. When the calibration is not enabled, the

related parameters are hidden.

inL(

Input Low Calibration

.

Enter the value corresponding

to the low scale signal applied to the analog input.

ink(

Input High Calibration

.

Enter the value corresponding

to the full scale signal applied to the analog input.

rstr

Restore

.

Restores the factory calibration for all inputs

and outputs, disregarding modifications carried out by

the user.

(j

Cold Junction

.

This screen is for information purpose

only.

Pas.(

Password Change. Allows defining a new access

password, always different from zero

Prot

Protection. Sets up the Level of Protection. See Table 04.

CONFIGURATION PROTECTION

The controller provides means for protecting the parameters

configurations, not allowing modifications to the parameters values,

avoiding tampering or improper manipulation. The parameter

Protection (

PROt

), in the Calibration level, determines the

protection strategy, limiting the access to particular levels, as shown

by the Table 04.

PROTECTION

LEVEL

PROTECTION CYCLES

1

Only the Calibration cycle is protected.

2

Calibration and Input cycles.

3

Calibration, Input and Alarms cycles.

4

Calibration, Input, Alarms and Tuning cycles.

5

All cycles are protected, but the SP screen in

the operation cycle.

6

All cycles are protected, including SP.

Table 04 – Levels of Protection for the Configuration

ACCESS PASSWORD

The protected levels, when accessed, request the user to provide the

Access Password for granting permission to change the

configuration of the parameters on these levels.

The prompt

PASS

precedes the parameters on the protected levels.

If no password is entered, the parameters of the protected levels can

only be visualized.

The Access Password is defined by the user in the parameter

Password Change

(

PAS.(

), present in the Calibration Level. The

factory default for the password code is 1111.

PROTECTION ACCESS PASSWORD

The protection system built into the controller blocks for 10 minutes

the access to protected parameters after 5 consecutive frustrated

attempts of guessing the correct password.

MASTER PASSWORD

The Master Password is intended for allowing the user to define a

new password in the event of it being forgotten. The Master

Password doesn’t grant access to all parameters, only to the

Password Change

parameter (

PAS(

). After defining the new

password, the protected parameters may be accessed (and

modified) using this new password.