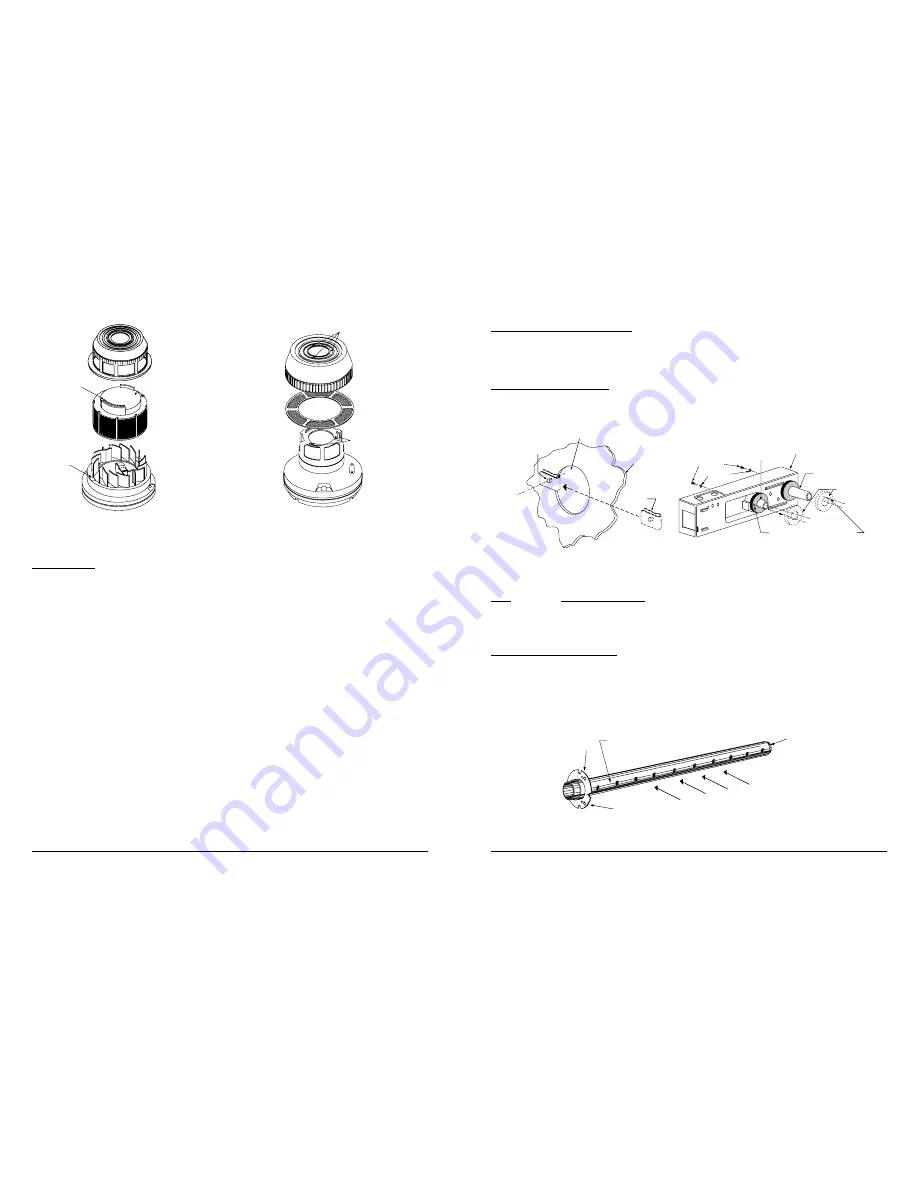

STEP 2. DRILL THE MOUNTING HOLES

Remove the paper backing from the top and bottom of the t emplate. Affix the template to the air duct at the desired

mounting location. Make sure the template lies flat and smooth on the air duct. Center punch hole targets and remove

the template. Drill the holes as indicated on the template. Slide the two speed nuts over the two small holes (Hole A)

next to the sampling tube bushing holes (Hole B) previously drilled in the duct. (See Figure 2.)

STEP 3. MOUNT DUCT HOUSING

Remove the duct housing cover. Slide the foam gaskets over the tube bushings as shown in Figure 2B. Make sure

the two small holes in the gaskets line up with the two base mounting holes. Put one 5/16-inch O-ring over each of

the two #10 sheet metal screws. Use the two sheet metal screws to secure the duct housing to the duct.

CAUTION: Do not overtighten the screws.

HOLE B

HOLE A

DUCT

WALL

SPEED

NUT

SCREW HOLES FOR ATTACHING

DETECTOR HOUSING TO DUCT

FOAM GASKETS

EXHAUST TUBE

(EXTENSION BUSHING)

DUCT DETECTOR

HOUSING

O-RINGS

MOUNTING

SCREWS

INLET SAMPLING

TUBE BUSHING

A78-2046-00

A78-2045-00

Figure 2A. Speed Nut Mounting Location

Figure 2B. Installation of Foam Gaskets Over

Sampling Tube Bushings

TABLE 1. SAMPLING (INLET) TUBES

TUBE

OUTSIDE DUCT WIDTH

ST-1.5

1 to 2 ft.

(0.3 to 0.6 m)

ST-3

2 to 4 ft.

(0.6 to 1.2 m)

ST-5

4 to 8 ft.

(1.2 to 2.4 m)

ST-10

8 to 12 ft.

(2.4 to 3.7 m)

STEP 4. INSTALL THE INLET TUBE

The inlet tube (shown in Figure 3) is identified by a series of air inlet holes on the tube. This tube must be purchased

separately. Order the correct length, as specified in Table 1, for the width of the duct where it will be installed. The

exhaust tube is molded into the base of the duct housing.

The inlet tube is always installed in the right house bushing, with the air inlet holes facing into the air flow. To assure

proper installation, the tube mounting flange is marked with arrows. Mount the inlet tube so that the arrows point into

the air flow. Figure 4 shows the various combinations of tube mounting configurations with respect to air flow.

INLET

TUBE

END

PLUG

AIR HOLES

ARROWS

MUST FACE

INTO AIR FLOW

AIR FLOW DIRECTION

FLANGE

A78-2047-01

Figure 3. Air Duct Detector Inlet Sampling Tube

N500-04-00

10

I56-507-06

N500-04-00

3

I56-507-06

REMOVABLE HEAD COVER

CLEANABLE SCREEN

HEAD COVER

REMOVAL SLOT

VANED CHAMBER

TEST SLOT

P/N RS24 (W/O THERMAL)

A78-1213-01

–Wiring terminal screw tightness

SPECIFICATIONS

Length:

14.5 inches

(36.7 cm.)

Width:

5 inches

(12.7 cm.)

Depth:

4 inches

(10.2 cm.)

Weight:

3.5 lbs.

(1.6 kg.)

Operating Temperature Range: 32

°

to 120

°

F

(0

°

to 49

°

C)

Operating Humidity Range:

10% to 93% Relative Humidity

Duct Air Velocity:

500 – 4000 ft./min. (91.4 – 1219.2 m/min.)

Electrical Ratings for DHX-502A

Refer to the head's electrical ratings.

Accessories

Part No.

Remote LED

RA400ZA

Piezo Alert Sounder

PA400

Replacement Filters

F36-05-00

Magnet

M02-04-00

End Plug For Sampling Tube

P48-21-00

Installation Kit (Parts bag)

A2650-01

Ionization Replacement Screen

RS14

Sensitivity Test Kit

MOD400 or MOD400R

Ionization Cover Removal Tool

CRT400

Remote Test Station

RTS451/RTS451KEY

Programming Specifications/Requirements For Intelligent System Control Panels.

CAUTION:

The CPX-551 and SDX-551 models can be used with the DHX-502 if the following constraints are

observed.

There is a limit to the number of devices per zone that can have their LEDs latched ON. The actual number of devices

is determined by the control panel and its ability to supply LED current. Refer to the AM2020/AFP-1010 Programming

Guide (15530) for details.

Figure 10. Photo Head Exploded View

HOUSING

LOCK PRONGS

REMOVABLE SCREEN

(P/N RS14)

REMOVABLE

COVER

FOR

CLEANING

HEAD COVER

LOCK PRONGS

A78-1812-07

Figure 11. Ion Head Exploded View