80-9369-0120-020 (09-08)

General Product Information

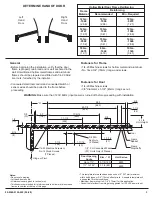

(See illustrations on page 2 for location of switch and valves.)

Function and Operation Sequence

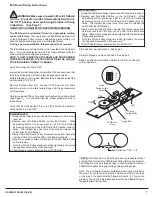

• Selector Mode Switch

• "SC" Speed Control Valve

• "PA" pressure Adjustment Valve

– This is a three (3) position switch that

has positions marked "OFF” “ON” “H/O".

– "ON" position – Unit is in standby, capable of function

activation either by a remote switch or scanner; or by the unit's

integral switch depending upon the Activation Mode.

– "H/O" position – Indefinite hold open. Door will hold open until

power is interrupted.

Power Assist Function Only (PAS).

These units must be manually pushed to the full open position

for this indefinite Hold Open function to operate.

– "OFF" position – All signal inputs are disabled, rendering all

power functions inoperative. The unit functions as a standard

hydraulic door closer.

– Power Assist Function Only.

Adjusts the force required to open the door.

– Power Operator Funtion Only (POR).

Adjusts the opening speed of the door.

Important:

From closed position to 80 degrees must be 3

seconds or longer and 4 seconds or longer to the

fully open osition.

Factory set adjustment for opening force. Will not generally

require adjustment:

Important:

Power Operator Function Only (POR): The force

required to prevent a door from opening or closing

must not exceed a 15 lbf. (67N) applied 1" (25mm)

from the latch edge of the door at any point in the

opening or closing cycle.

p

VESTIBULE OPERATION

POWER OPERATOR FUNCTION – “POR”

In either Power Operator or Power Assist Function, initiation

of a power cycle may be performed on a delayed basis. This

feature, referred to as Vestibule Operation, allows placement

of the initiating switch at a remote location from the Door

Operator. The adjustable VEST DLY rotary switch/timer pot is

provided for selection a leng h of delay, appropriate for the

particular installation. The basic sequence is shown below:

• Initiate vestibule delay cycle JP1-INV from JP1-OUTV of

another unit or from a switch.

• Set VEST DLY rotary switch/timer pot to delay initiation of

pump motor.

• Upon initiation of pump motor, Power Operator or Power

Assist Function will start.

In the power operator function, initiation of the unit causes

the operator to fully open the door under its own power,

sustain the opened position for a set duration, and then

release and close.

The basic sequence is:

1. Initiate power cycle through any of the following JP1

terminal functions: AUX1, AUX2, RFT, JP1-INV, the L1

limit switch input, the H/O of slide switch or the JP1-O/O

terminal.

2. If JP1-INV is the power cycle initiating signal, read the

VEST DLY rotary switch/timer pot to determine how long

to wait before the power cycle starts.

3. Read the EXSOL DLY rotary switch/timer pot to determine

how long solenoid should be energized or de-energized,

depending upon function required.

4. Read th SW1-2 (A/D) dip switch to determine how long

solenoid should be energized.

5. Read the M DLY rotary switch/timer pot to determine how

long before the pump motor and solenoid valve tu n on.

6. When ELS board reaches upper taught limit, door is fully

open.

7. Pump motor turns off.

8. Read the CL/AS DLY rotary switch/timer pot to determine

the length of temporary hold open.

9. Solenoid valve turns off, releasing door from temporary

hold open.

10. Door closes and operator waits for next power cycle

in tiation.

Additional door open signals received during Step 8 of the Power

Operator function will cause the cl sing de ay timer to be reset to

the beginning.

t

e

r

i

o

l

Exceptions to the Power Operator Function

POWER ASSIST FUNCTION – "PAS”

Following is an explanation of the inputs that can modify the

basic flow of the Power Operator function described above.

1. If terminal JP1-PDET is signaled the door will not open if it

is closed or the door will not close if it is open. This signal

is normally used to connect to a presence detector which

will prevent the door from opening or closing when

someone is in the area of detection. Note that JP1-0/0 will

override the PDET signal.

2. If JP1-0/0 is signaled the door will open independently of

the state of JP1-PDET or JP2-E signals.

3. If the H/0 slide switch is set, the door will open and remain

open. JP1-PDET, JP1-0/0 or JP2-E will override the H/0

signal.

4. If JP2-E is signaled, the power cycle will terminate and the

door will close. JP1-0/0 will override the JP2-E signal.

5. The door must reach its fully open position within 7

seconds after it has started opening or the pump motor

and solenoid valve will be turned off allo ing the door to

close.

6. If the door is in the closed position, and not in the Manual

or Emergency mode, signaling RFT will initiate a door

power cycle. The door will remain open until PH1-RFT is

again signaled or until JP2-E is signaled. If the door is in

the open position, the RFT signal will close the door,

therefore, the door can be "toggled" between an open and

closed position.

In the Power Assist function, initiation of a power cycle

causes the pump motor and solenoid valve to engage,

requiring minimal force to open or close the door. The ease

of operation is sustained for an adjustable duration, after

which the motor and solenoid are turned off, causing the

door to close. If the door is fully opened during the power

cycle, the motor will disengage for the remainder of the

cycle. The solenoid will remain engaged for the duration of

the cycle. The basic flow for the Power Assist mode is the

same as the Power Operator mode except that the 7 second

time-out function is not in effect.

w

6