80-9369-0120-020 (09-08)

Activation Mode – (Push and Go)

Functions – Power Operator / Power Assist:

• Rotate the “SC” Valve Counter-Clockwise to adjus opening speed

(POR) or opening force (PAS).

• Rotate the “PA”Valve Clockwise if needed to adj st pressure.

(See illustrations on page 2 for Dip Switch and Valve location.

t

u

Adjust the “SC” valve so the the door does

not open when activated, but opening force is reduced below A.D.A

requirements. The “PA” valve is factory set and should not need

adjustment. Adjust if needed to obtain proper opening forces.

Power Assisted Opening:

Obstruction During Opening:

Obstruction During Closing:

Obstruction Sensitivity

The door will stop and close under spring force.

The door will stop and the unit will reopen the door.

If the

Obstruction During Closing is detected a second time, the door will

not attempt to reopen and will attempt to close under spring force.

The time delay of the obstruction feature can be adjusted in the field

as required.

The unit has been factory-configured to respond

immediately to an obstruction.

In certain applications where

excessive wind or excessive stack pressure is present, a delay of 1,

3, or 5 seconds can be selected by toggling dip switches T1 and T2

on the ELS board.

Obstruction Operation:

TEACHING CLOSED AND OPEN DOOR POSITIONS:

5

The following adjustments mechanical, hydraulic and electrical are

listed in a suggested sequence.

Make sure that power to unit is

.

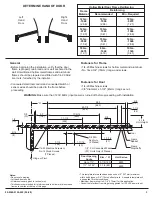

• Set Closing Power. Use 11/16" wrench or socket. Turn Power

Adjustment Nut clockwise to increase door closing power. Door

control is shipped set at midpoint of power setting. Maximum

closing power can be achieved with 5 (360°) turns of the power

adjustment nut for a regular PowerMatic, 7 turns if unit is a

Barrier Free (BF) unit.

– Use 1/8" hex wrench

• Closing Cycle – Make adjustments, as necessary, to the Sweep

Speed "S" valve and Latch Speed "L" valve. See illustration on

Page 2. Turn valves clockwise to reduce speed, counter

clockwise to increase speed.

NOTE:

MECHANICAL ADJUSTMENT

HYDRAULIC ADJUSTMENT

OFF

Adjustments for the PowerMatic Product

– Adjust "CL/AS DLY" Rotary Switch/Timer Pot on the printed

circuit board as necessary using a standard screwdriver with a

1/8" wide blade. Adjustable for 0 to 30 seconds (see chart

below).

– Power Assist Function Only:

Adjusts the length of time the motor will assist with opening

from the time the motor is activated.

– Power Operator Function Only:

Adjusts the length of time the door remains at the fully open

position after the operator function shuts off.

• Opening Cycle – Adjust Backcheck, "B" valve, as necessary, for

hydraulic resistance to door opening in the backcheck range. See

illustration on Page 2.

1/8"

Hex

Key

Slower

Closing

Faster

Closing

Closing Cycle

Closed

10°

L

a

tc

h

R

a

n

g

e

S

w

ee

p R

ang

e

1/8"

Hex

Key

Increase

Cushion

Decrease

Cushion

Opening Cycle

Backche

ck

O

p

e

ni

ng

Length of Time

(Seconds)

Setting

0

2

5

10

15

20

25

30

0

1

2

3

4

5

6

7

• If desired, install No. 668 Security Plate over notch in cover to

conceal the Selector Mode Switch when cover is installed.

• Install cover with mounting screws removed at beginning of

installation.

1

0 9

8

7

6

2

3

4

5

CL/AS DLY

S2

Illustration for CL/AS DLY

Rotary Switch/Timer Pot

From Printed Circuit Board

NOTE:

oo much Backcheck, "B" valve, can affect

he

operation of the units pump, preventing units rom fully

opening the door. This valve may requir fine tuning after all

other adjustments have bee made.

T

t

f

e

n

• Backcheck Position "P" valve is closed. Open by turning counter

clockwise, only if backcheck cushioning is required to begin at a

greater degree of door opening than the approximately 75° it is

set for.

ELECTRICAL:

Turn power input to unit on.

Selector Mode Switch – Set to the “ON” Position for normal use.

Time

B

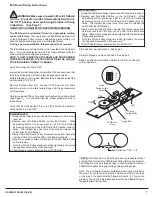

ELS Dip Switch T1

B

ELS Dip Switch T2

1 Sec.

5 Sec.

Immediate

3 Sec.

A

A

B

B

A

A

Push And Go

A

ENABLED

DISABLED

B

ELS Dip #3 DN

Selectively Activated

Automatically Activated

Mode

Function

Power Operator

Power Assist

A

B

ELS Dip #4 PAS

Main Board Dip #1 P/A

OFF

ON

OBSTRUCTION DIP SWITCH SETTINGS:

!

Before operating, the PowerMatic 6900 must be “taught” the

fully closed and fully open door positions.

“

l

- Turn Power Input to Unit “ON”.

- With the door fully closed, press and release the BLACK

pushbutton on the ELS board. The ELS system will store this

position as closed and begin the 10 second “Teaching Mode”.

- Within the 10 second time frame, manually open the door to the

desired fully open position. While holding the door open in this

position, press and release the WHITE pushbutton on the ELS

board. The ELS system will store this position as open.

- Let the door return to the closed position.

This will end the

“Teaching Mode” regardless if the 10 second time frame has

elapsed.

- Set the Selector Mode Switch to the “ON” position for normal

operation or “H\O” for i

hold open.

-

If unit does not respond to teaching or if the ELS LED

began flashing when power input was first turned on and

continues to flash , see ELS Reset Instructions on page 8.

WARNING:

A

NOTE:

Verify that dip switch #3 on the ELS board is

in the “ ” position to disable the Push and Go Feature. Verify

the Selector Mode Switch is in the“OFF”position (Page 2)

• ELS board comes from factory with potentiometer timed” and

ready for unit to be taught open and c osed door positions.

•

ndefinite