80-9369-0120-020 (09-08)

General

Fasteners for Frame

Hollow Metal Door Frame Reinforcing

Frame

Material

12 Ga.

.1046

14 Ga.

.0747

16 Ga.

.0598

18 Ga.

.0478

(2.66)

(1.90)

(1.52)

(1.21)

Recommended

12 Ga.

.1046

10 Ga.

.1343

10 Ga.

.1343

8 Ga.

.1644

(2.66)

(3.41)

(3.41)

(4.18)

Min. Required

18 Ga.

.0478

12 Ga.

.1046

12 Ga.

.1046

10 Ga.

.1343

(1.21)

(2.66)

(2.66)

(3.41)

Reinforcing

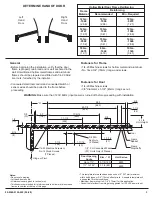

DETERMINE HAND OF DOOR

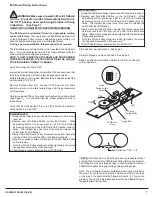

• Before beginning the installation, verify that the door

frame is properly reinforced and is well anchored in the

wall. Unreinforced hollow metal frames and aluminum

frames should be prepared and fitted with 1/4-20 blind

rivet nuts, furnished by the installer.

• Concealed electrical conduit and concealed switch or

sensor wires should be pulled to the frame before

proceeding.

• 1/4-20 Machine screws for hollow metal and aluminum.

• No. 14x2-3/4" (70mm) long wood screws.

Fasteners for Door

• 1/4-20 Machine screws.

• 3/8" diameter x 1-3/4" (45mm) long sex nut..

WARNING: Make sure that (120V, 60Hz) input power is turned off before proceeding with installation.

1/2

(13)

5/16

(8)

7-1/4

(184)

1-11/16

(43)

1-7/16

(37)

5/8

(16)

3/8

(10)

4.0

(102)

“A”

11-1/2

(292)

17-5/16

(440)

23-7/8

(606)

26.0

(660)

3/8

(10)

1-1/4

(32)

Notes:

• Do not scale drawing.

• Left hand door shown.

• All dimensions are given in inches (mm).

• Thickness recommended for reinforcements in hollow metal doors and

frames is charted at the top of this page.

• This template information based upon use of 5" (127mm) maximum

width butt hinges or 3/4" (19mm) offset pivots. A separate template will

be supplied for other conditions.

• Conduit hole farthest from hinge is suggested for 120 VAC power input.

• Maximum frame reveal is 6-7/8” (175mm) for this application.

1/4-20 Machine Screws or

No. 14 Wood Screws

(7 Places)

For Concealed Wired

Units Only (2 Places)

3/8 DIA.

Sex Nuts

(2 Places)

Door

Frame

Rabbet

Frame

Stop/Soffit

4-1/8

Unit Height

3

Left

Hand

Door

Right

Hand

Door

Door Opening

Angle

Dim – “A”

Unit Series

Up to 110°

111° to 180°

5-7/8 (150)

3-1/8 (80)

6930

6920

c

L

Hinge or Pivot

7/8”

(23)