Page 9

1.2 ELECTRICAL INSTALLATION

IT IS VERY IMPORTANT

that the mating connector

and the encoder body be isolated from electrical

ground in the wiring and conduit to prevent motor or

machine shaft eddy currents from going to ground

through the encoder bearings, as this will damage the

bearings over time. To insure that this is being done,

it is suggested that a plastic wiring/conduit adaptor or

non-conductive conduit is used to isolate the connector

from any metallic surface or conductive conduit. Please

see special note under table 1, for proper encoder

connector shielding. Also, to allow for proper encoder

grounding, the motor must be wired and grounded per

your local NEC Requirements.

Electrical connections are made to the sensor

module through a standard 1/2 inch NPT liquid tight

flexible conduit. The nipple length may be changed

to extend the outlet box if desired. Interconnection

cable recommendations are as follows: stranded

copper, 22 through 16 gage, braided or foil with drain

wire shielding 0.05 F maximum total mutual or direct

capacitance, outer sheath insulated. Shrink tubing may

be placed over any wires without insulation. For lengths

over 100 feet, use 18 gage or larger, to a maximum

of 1000 feet. If shielded twisted pair wire is used, do

not cross channels. Keep each pair of complementary

channel outputs together in a single twisted pair (e.g.,

A and A).

IMPORTANT: Reversing power and common will

not damage the unit. However, applying power to

any of the sensor outputs may cause damage.

Grounding:

For applications with high ground

potential differences, DO NOT ground the encoder

through both machine and controls end. Connect

the shield at the controls end only.

NOTE: If the

shield is connected at both ends, grounding

problems that degrade system performance can

result.

CE Grounding Measures

– For best EMC

immunity the cable screen must be grounded on

both encoder and controls end. For cable lengths

longer than 30m or outdoor applications, additional

measures must be implemented to comply with

CE requirements. Connection of the encoder

to DC power supply network is prohibited if CE

compliance is required. CE-compliant products are

tested to EN61326-1 EMC.

In all cases, system CE compliance is ultimately the

responsibility of the manufacturer integrating the

encoder.

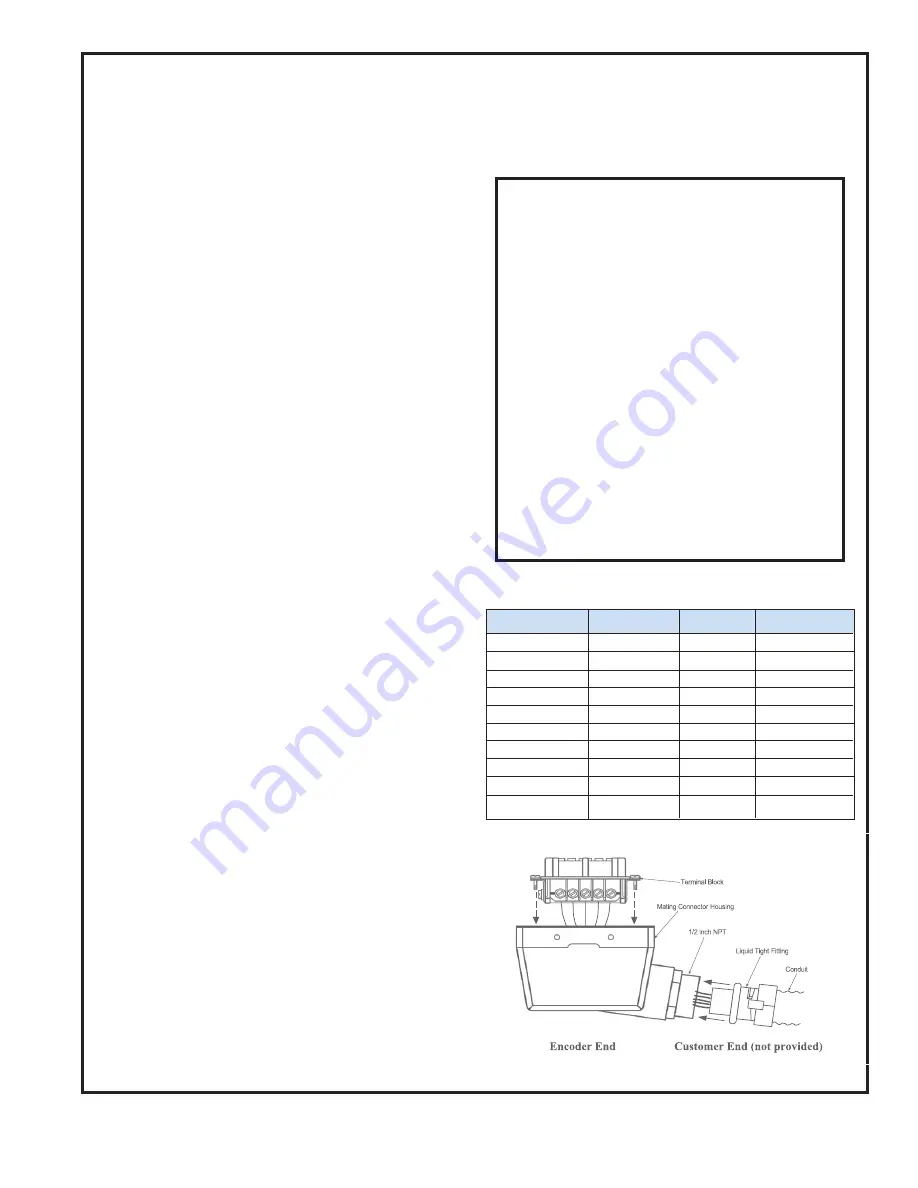

1.3 QUICK RELEASE CONNECTOR HOOD WIRING

To install the Quick Release Connector, perform the

following steps.

1.Remove the four screws from the mating connector

housing that hold the terminal block in place. Re-

move terminal block from housing.

2.Insert wiring through liquid tight flexible seal and

mating connector housing. Leave enough wire ex-

posed to comfortably reach the terminal block. Wire

to terminal block according to wire code in Table 1.

A similar wiring list is attached to enclosure.

3.Tighten Liquid Tight fitting on housing. OPTIONAL:

In some hostile environments, seal between con-

nector body and Sensor Module can be improved

by smearing a sealant (silicone grease, etc.) on the

neoprene seal of the connector.

4. Mate connector into place on sensor mount and

snap the two latches into place. If only one sensor is

being installed, ensure cover plate is installed over

other sensor hole.

Table 1. Signal Coding Table

* Index (Z) optional. See Ordering Information

Common

B

A

Z*

No Connection

Vcc (5-26 VDC)

B

A

Z*

Shield

1

2

3

4

5

6

7

8

9

10

Black

Green

Blue

Violet

N/A

Red

Yellow

Gray

Orange

Braid

Signal Connector Pin Pigtail Cable MS 3102E18-IT#

F

B

A

C

E

D

I

H

J

G

Quick Release Connector Hood Wiring

To install the Quick Release Connector, perform the following steps:

1. Remove the four screws that hold the terminal block in place from mating connector hood. Remove the terminal block from the

hood.

2. Insert wiring through the liquid tight flexible seal and the mating connector hood. Enough wire should be left exposed to

comfortably reach the terminal block.

3. Wire to terminal block according to the wire code in Table 1. A similar wiring list is attached to the enclosure.

4. Replace the terminal block in the connector hood. Insert and tighten the four mounting screws.

5. Tighten the liquid tight fitting on the housing.

6. OPTIONAL: In some hostile environments, seal between connector body and sensor module can be improved by applying a

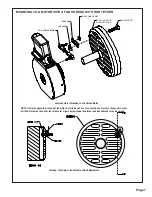

Figure 7: Industrial Latching Connector

Uninstalling the Encoder

1. Loosen the 10-32 socket head cap screws in split shaft collar. Loosen 10-32 x • hex bolt attached to the bracket or bolt on

the motor. Carefully remove the encoder and torque arm assembly.

2. Perform the installation steps in reverse order.

Returning Equipment to Dynapar

If it is necessary to return the unit for repair or replacement, a Return Goods Authorization (RGA) number must be obtained from a

factory representative before returning the equipment to our service department. When returning an instrument for service, the

following information must be provided before we can attempt any repair.

1. Instrument model and serial number.

2. User’s name, company, address, and phone number.

3. Malfunction symptoms.

4. Description of system.

5. Returned Goods Authorization number.

Please consult the factory for shipping instructions.