Page 5

STEP 6: SLIDE ENCODER ON SHAFT

Carefully slide the encoder all the way down until the tether rests on

the motor face without any stress on the tether. Do not tighten the

shaft clamp on the encoder yet

STEP 7A: SECURE TETHER TO MOUNTING FACE (MOTOR

MOUNT)

Rotate the tether arm until it is at the correct orientation and is aligned

with the mounting holes on the the motor or equipment. Install one

steel washer on both sides of the nylon washer. Fasten the tether arm

to the motor or machine housing using the supplied 3/8” bolt (4.5” C-

face applications) or 1/2” bolt (8.5” C-face applications). Ensure that

there is no stress or flexing of the tether arm when secured.

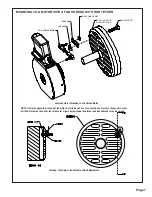

STEP 7B: SECURE TETHER TO MOUNTING FACE (FAN COVER

MOUNT)

Slide and insert the T-bolt as shown in the figure into the fan cover.

Use the supplied insulating hardware and washers as shown. Tighten

the jamnut to firmly secure the tether.

STEP 8: TIGHTEN ENCODER CLAMP ONTO MATING SHAFT

Check to make sure that the tether is still in its “unstressed” condi-

tion. Adjust position of encoder on shaft if necessary and then tighten

the shaft clamp on the encoder. Tighten clamp to stated torque value

provided on encoder datasheet (50-55 in-lbs.).

NOTE: ENCODER MODELS WITH SPLIT CLAMPS HAVE TWO SCREWS

TO TIGHTEN DOWN. PLEASE ENSURE THAT BOTH SCREWS ON THE

CLAMP ARE TIGHTENED DOWN SECURELY. YOU MAY HAVE TO RO-

TATE THE SHAFT TO TIGHTEN BOTH SCREWS DOWN.

STEP 9: GOOD INSTALLATION CHECK POINT

Follow the 3 step installation check to ensure a good installation thus

far. Refer to figure above for key reference dimensions

A. Check clearances from mounting face.

Ensure you have a

minimum clearance of 1/16” between the encoder shaft and any non-

rotating surface closest to the encoder shaft

B. Check tether installation.

Make sure that the tether is unstressed.

There should be no visible bending or deflection on any surface of the

tether. Visible tether deflections should be corrected immediately. If

the tether is bent or distorted, DO NOT USE, and call the factory for a

replacement tether. Tether installation is critical to the long life of the

bearings and improper tether installation will lead to excessive bear-

ing loads and encoder failure.

C. Check wobble of encoder housing.

Turn the shaft by hand and

make sure that the shaft turns freely and does not produce excessive

runout/wobble of the encoder. Most encoder installations will have

wobble arising from shaft tolerances. Measure the wobble on the

visible back face of the encoder. A wobble of less than 0.007” TIR will

not have any adverse effect on encoder performance. In general, the

lower the TIR of runout, the better.

"C"SIZE

TOLERANCES UNLESS

INDICATED:

C D.T.C.

TITLE

DRAWING NUMBER

UL

RoHS

REACH

CE

CSA

TUV

ATEX

TM

27-DEC-2019

HT55_MOUNT

1 OF 2

-

RELEASED:

DATE:

/

/

SHEET REV

CHECKED:

DATE:

APPLICATION:

27-DEC-2019

PRO/E MODEL: HT55_MOUNT

.005

.01

1/4

DRAWN:

DATE:

X

X

FINISH:

HT55_MOUNT

1:4

.XXX

.XX

ANGLES

FILE NAME:

SCALE:

COMPLIANCE REQUIRED

MATERIAL:

UNITS: INCH

REV

ECN

DATE

APPROVED

MOUNTING HOLE

FLAT STEEL WASHER

FLAT NYLON WASHER

FLANGED NYLON WASHER

FLAT STEEL WASHER

HEX BOLT

MOUNTING FACE OF MOTOR

TETHER