708709C (Replaces 708709B)

INSTALLATION / PERFORMANCE CHECK LIST

INSTALLER NAME:

CITY:

STATE:

INSTALLATION ADDRESS:

CITY:

STATE:

UNIT MODEL #

UNIT SERIAL #

Minimum clearances per

page 4?

YES

NO

Is the unit properly installed and

leveled?

YES

NO

Does condensate drain properly

in both drain tubes?

YES

NO

Has the owner’s information been

reviewed with the home-owner?

YES

NO

Has the literature package been

left near the appliance?

YES

NO

ATTENTION INSTALLERS:

It is your responsibility to know this product better than your customer.

This includes being able to install the product according to strict

safety guidelines and instructing the customer on how to operate

and maintain the equipment for the life of the product. Safety should

always be the deciding factor when installing this product and using

common sense plays an important role as well. Pay attention to all

safety warnings and any other special notes highlighted in the manual.

Improper installation of the air handler or failure to follow safety

warnings could result in serious injury, death, or property damage.

These instructions are primarily intended to assist qualified individuals

experienced in the proper installation of this appliance. Some local

codes require licensed installation/service personnel for this type of

equipment. Please read all instructions carefully before starting the

installation. Return these instructions to the customer’s package for

future reference.

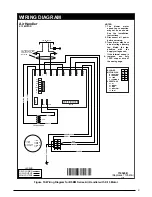

ELECTRICAL SYSTEM:

Electrical connections tight?

YES

NO

Line voltage polarity correct?

YES

NO

Supply Voltage: ____________________________

_______

(V)

Has the thermostat been calibrated?

YES

NO

Is the thermostat level?

YES

NO

Is the heat anticipator setting correct?

YES

NO

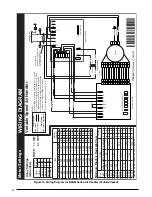

VENTING SYSTEM:

Is there adequate fresh air supply for

ventilation?

YES

NO

Vent free from restrictions?

YES

NO

Filter properly installed?

YES

NO

Filter clean?

YES

NO

Flue connections tight?

YES

NO

Is there proper draft?

YES

NO

Return Air Temp: ____________________________

_______(° F)

Supply Air Temp: ____________________________

_______(° F)

Temperature Rise: _____________________________

_____(° F)

PROPOSITION 65 WARNING: This product

contains chemicals known to the state of

California to cause cancer, birth defects or

other reproductive harm.

WARNING:

Specifications & illustrations subject to change without notice or incurring obligations.

O’ Fallon, MO | Printed in U.S.A. (08/11)

Содержание B5BM

Страница 27: ...27...