·

Adjust vacuum valve thumb wheel to zero

force (spring backed off).

While system in operating, visually watch the

spray pattern from the nozzles.

If the system is completely sealed (no vacuum

leaks in the water line) then once the system is turned

on for the first time all nozzles should start spraying

starting with the nozzles closest to the vacuum valve.

The negative pressure created in the water line by the

high velocity air exiting the nozzles will cause the

water line to fill with water, the farther the nozzle is

from the vacuum valve the longer it will take for the

water to reach that nozzle. Once the system has gone

through the priming stage, it should start spraying

within seconds after the system has been turned on

after a shut down. The priming stage should not take

any longer than five minutes. If the system fails to fully

prime after five minutes this may indicate a problem.

CHECKING FOR VACUUM LEAKS

The best way to check for leaks is to disconnect

the water line from the vacuum valve outlet fitting and

connect it directly to the water supply line. This will

pressure the line and any leaks should cause dripping

allowing location and repair of the leaks.

To test the operation of the vacuum valve;

·

Reduce the control panel pressure to 40 psig.

·

Adjust thumb wheel tension by turning it in a

clockwise direction. There should be a visual

difference in the output of the nozzles as more

tension is applied to the spring. Be sure not to

press down on the thumb wheel while turning

it.

·

Release the thumb wheel tension and, once

again, there should be a noticeable change in

the nozzle output.

The spring tension of the vacuum valve restricts

the flow of water to the nozzles by changing the

required amount of vacuum needed to operate the

vacuum valve. Since the nozzles can only generate a

fixed amount of vacuum (negative pressure) the flow

rate of water is reduced which causes a finer spray

and less output. If there was a vacuum leak in the

water line it may not be noticeable with the vacuum

valve spring tension set to zero, but it should become

noticeable with greater tension applied to the spring.

A good indication of a small leak would be very little

visual difference in nozzle output while performing this

test.

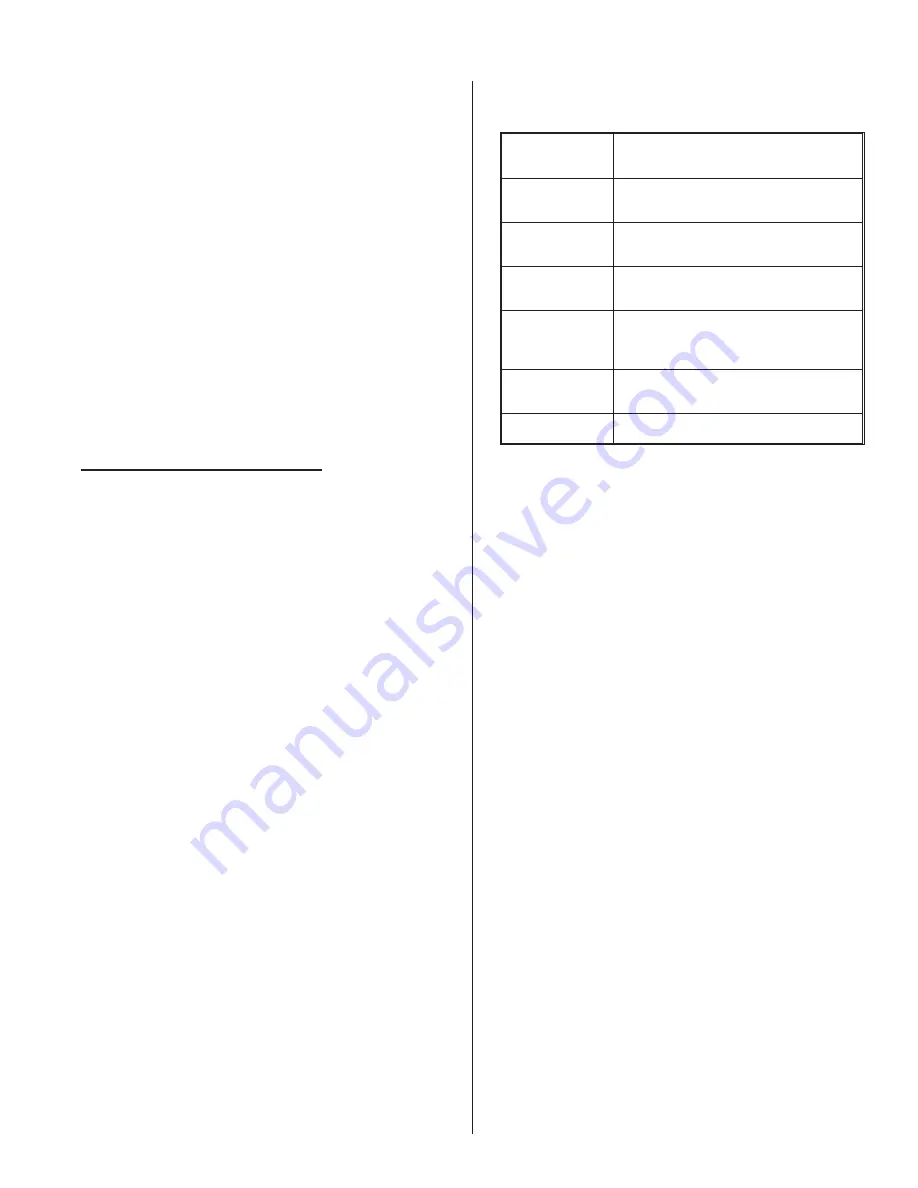

Table #2

Rebuild Kits

Part #

Description

1603115

Rebuild Kit for 1603104 Norgren

pilot water regulator

1603117

Diaphragm kit for 1609412 watts pilot air

regulator.

1603118

Rebuild kit for 1603001 Norgren panel

mounted air regulator.

1603119

Rebuild kit for 1603002 Norgren Brass

water pressure regulator for vacuum

valves

1603120

Seal Rebuild kit for 1609209 AFE

Nozzle.

1603122

Vacuum Valve Diaphragm Rebuild kit

- 19 -