18

EN

Appendix

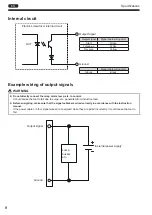

Symptoms

Location to investigate

Solution

The electric screwdriver

gets hot

Is the ON time of the electric

screwdriver too long?

Alternatively, is the OFF time too

short?

Review the operation time.

The rated operating time is 0.5 sec. ON and 3.5 sec.

OFF.

Aim at 15 screws per minute. (p. 6)

Is the rated voltage input?

Check the power source voltage, and input the rated

voltage.

Even though the output torque is set

to the specification lower limit value,

does the screwdriver get hot to a level

where you cannot touch it?

When the output torque becomes higher, the electric

screwdriver becomes hot.

If it gets hot to a level where you cannot touch even

with the specification lower limit value, a failure is

suspected.

The rotation speed is not

stabilized.

Is the electric screwdriver heating up?

Is it the same electric screwdriver?

The specification value of the rotation speed is a

standard.

The rotation speed could change due to

temperature or mechanical loss of the main unit

or grease conditions. Also, it differs by the unit.

(p. 6)

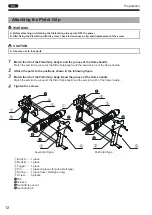

Maintenance and inspection

Store the tool according to the following warnings and cautions.

WARNING

Before performing maintenance and inspection, always turn off the power.

Do not disassemble or alter the tool.

Use genuine parts.

CAUTION

For repair or part replacement, ask your dealer.

Repair requires special knowledge and skills. If repair is performed at a place other than a specialty store, the

tool may not demonstrate its full performance or it could lead to an accident or injury.

Request repair with the failed status kept intact.

When requesting a repair, do not throw away damaged parts. It could be important information for investigating

the failure cause so do not change the status.

For the purpose of making proper use, request the following check and maintenance by an authorized service facility.

DLV30A series

DLV45A series, DLV70A series

Routine inspections and Parts to be

replaced

Number of Tightening (million)

0.5

1.0

1.5

2.0

0.25

0.5

0.75

1.0

Routine inspection

(1) Operation check

*1

*1

*1

*1

(2) Grease-up

*2

*1

Parts to be replaced

(1) Motor assembly

*2

*1

(2) Gear

*2

*1

(3) Rollers and Balls

*2

*1

(4) Bearing

*2

*1

*1: DLV45A series, DLV70A series

*2: DLV70A series