11

GB

1.

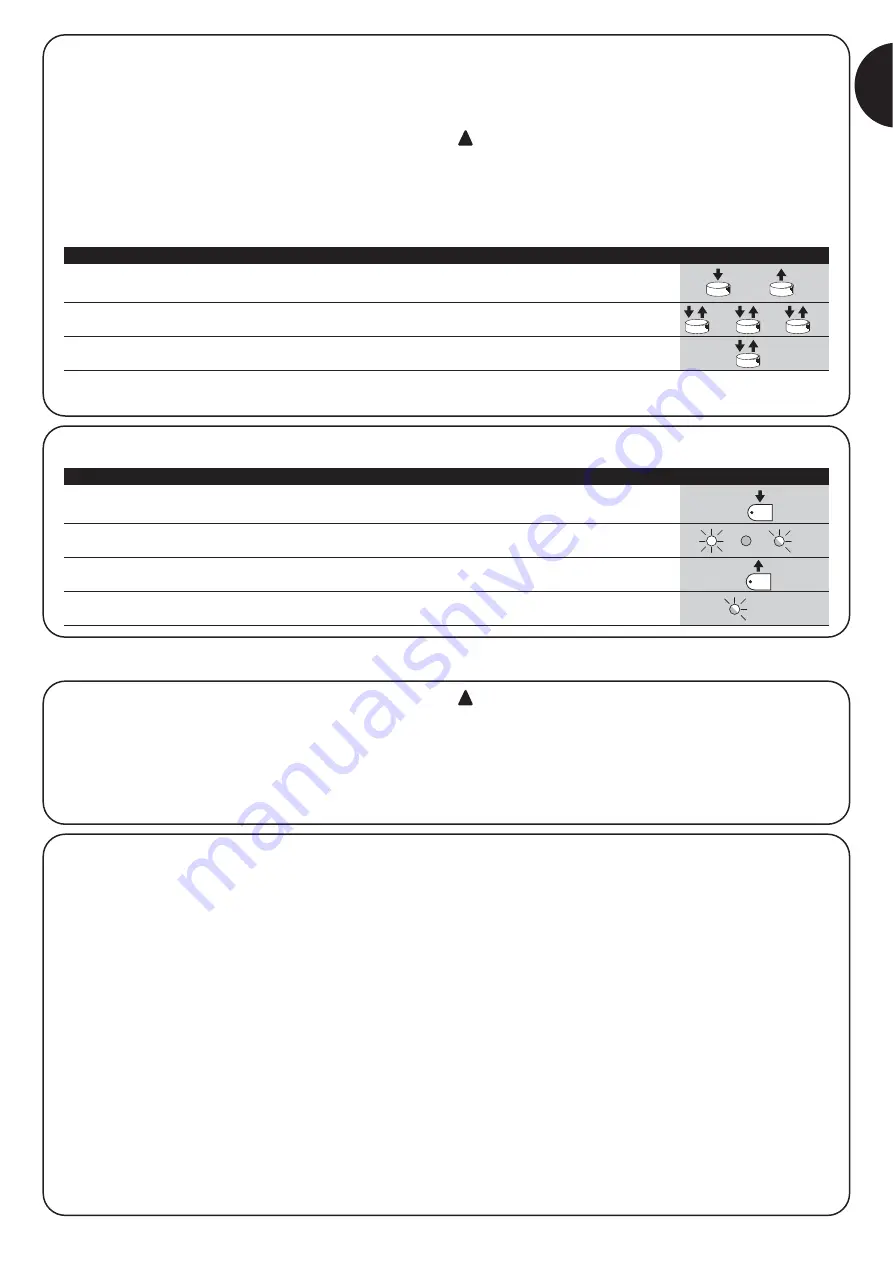

Press the button on the NEW radio transmitter and hold it down for at least 5s, then release it.

5s

2.

Press button on the previously memorized transmitter slowly 3 times.

1s

1s

1s

3.

Press the button on the new radio transmitter once slowly.

1s

At this point the new radio transmitter will be recognized by the receiver and will assume the characteristics of the previously memorized one.

If there are other transmitters to be memorized, repeat all the steps above for each new transmitter.

Table 11: for the “Remote” memorization of a transmitter

Example

4.7.3) Remote” memorization

A new radio transmitter can be memorized without directly operating

the buttons on the receiver. You need to have a pre-memorized oper-

ational radio transmitter. The “new” radio transmitter will inherit the

characteristics of the old one, i.e. if the old radio transmitter was

memorized in Mode 1, the new one will also be memorized in Mode

1. In this case, during the memorization stage you can press any but-

ton on the two transmitters. If, on the other hand, the old transmitter

was memorized in Mode II, the new one will also be memorized in

Mode II: you must press the button on the old transmitter which cor-

responds to the desired command, and the button on the new trans-

mitter to which you wish to associate that command.

Remote memorisation can occur in all those receivers

which are within range of the capacity of the transmitter.

Therefore, only the one involved in the operation should

be kept switched on.

!

Holding the two transmitters, position yourself within the operating range of the automation and perform the following operations:

1.

Press the radio button on the control unit and hold it down

2.

Wait until the radio LED lights up, then wait until it goes off, then wait until it has flashed 3 times

x3

3.

Release the radio button precisely upon the third flash

4.

If the procedure is successful, after a few moments the LED will flash 5 times.

x5

Table 12: to delete all the radio transmitters

Example

4.7.4) Deleting the Radio Transmitters

This is the most important stage in the automation system installa-

tion procedure in order to ensure the maximum safety levels. Testing

can also be adopted as a method of periodically checking that all the

various devices in the system are functioning correctly.

Testing of the entire system must be performed by

qualified and experienced personnel who must establish

which tests to conduct on the basis of the risks involved,

and verify the compliance of the system with applicable

regulations, legislation and standards, in particular with

all the provisions of EN standard 12445 which establishes

the test methods for automation systems for gates

!

5) Testing and commissioning

5.1) Testing

Each component of the system, e.g. safety edges, photocells, emer-

gency stop, etc. requires a specific testing phase. We therefore rec-

ommend observing the procedures shown in the relative instruction

manuals.

To test ROAD200 proceed as follows:

1. Ensure that the instructions outlined in this manual and in partic-

ular in chapter 1 "WARNINGS" have been observed in full;

2. Using the control or stop devices (key-operated selector switch,

control buttons or radio transmitter) test the opening, closing and

stopping of the gate and make sure that the leaves move in the

intended direction.

3. Check the proper operation of all the safety devices, one by one

(photocells, sensitive edges, emergency stop, etc.). In particular,

each time a device is activated the “OK” LED on the control unit

flashes 2 times quickly, confirming that the control unit recognizes

the event.

4. To check the photocells and make sure that there is no interfer-

ence with other devices, pass a 5 cm diameter, 30 cm long cylin-

der on the optical axis, first near TX, then near RX and finally at

the mid-point between them and make sure that in all these

cases the device is triggered, switching from the active to the

alarm status and vice-versa; finally, that it causes the intended

action in the control unit, for example that it causes the reversal

of the movement during the closing manoeuvre.

5. If the dangerous situations caused by the movement of the leaf

have been safeguarded by limiting the force of impact, the user

must measure the impact force according to EN Standard 12445.

If the adjustment of the “speed” and control of the “motor force”

are used to assist the system for the reduction of the impact

force, try to find the adjustment that gives the best results.