Temp.

These channels show the current temperatures.

Channel

Measured temperature on the outdoor sensor.

T1

Measured temperature on the flow line sensor.

T2

Measured temperature on the return line sensor.

T3

Measured temperature on the suction gas sensor.

T4

Measured temperature on the hot gas sensor.

T5

Measured temperature on the fluid pipe sensor.

T6

Measured temperature on the evaporator sensor.

T7

Adjust.

All setting are made on these channels.

Channel

Address for communication with SMO 10/VVM 300.

A1

Address for communication with METROAIR Styring/MET-

ROAIR 300/EVP 500.

When connecting to VVM this channel should be on 1.

When connecting to SMO 10 this must be selected so that

each F2015 in the system receives a unique address (1 – 9)

for communication with SMO 10.

For example 3 x F2015 in the same system are allocated

the addresses 1, 2 and 3. The F2015 that produces hot

water should be set to 1.

Max return temperature. When the return temperature

reaches the set value the compressor stops. The value is

adjustable between 25 and 50 °C. Factory setting 48 °C.

A2

With SMO/VVM connected this menu cannot be changed,

it is locked at 50 °C.

Connection difference return temperature. After the com-

pressor is stopped for a high return temperature, the return

temperature should drop by the set value in order to permit

the compressor to start. The value is adjustable between 0

and 10 °C. Factory setting is 4 °C.

A3

With SMO/VVM connected this menu cannot be changed,

it is locked at 2 °C.

Minimum time period in minutes between compressor

starts. The value is adjustable between 20 and 60 minutes.

Factory setting 20 minutes.

A4

Balance temperature, the set outdoor air temperature when

the additional relay (14) can be activated from channel A6

without affecting compressor operations. Additional heat

relay (14) is activated first after the set time on channel A6.

The value can be set between -15 (set stop temperature,

channel A7) and +10 °C. Factory setting is 0 °C.

A5

Continuous operating time with the compressor before

additional heat is permitted. The value is adjustable

between 0 and 120 minutes. Factory setting 120 minutes.

A6

Stop temperature, the set outdoor air temperature value

when the downtime relay (16) is activated, F2015 stops.

When the stop temperature is set between -7 and -15 °C

the flow temperature is limited linearly from -7 °C / 55 °C

to -15 °C / 45 °C. Factory setting is -15 °C.

A7

Minimum running time, heat production before new de-

frosting is permitted. The value is adjustable between 10

and 90 minutes. Factory setting according to the table be-

low.

A8

Minutes

Type

60

6 kW

50

8 kW

45

11 kW

Start temperature for permitted defrosting (evaporator

sensor). The value is adjustable between 1 and 5 °C. Factory

setting 1 °C.

A9

Stop temperature for defrosting (evaporator sensor). The

value is adjustable between 10 and 40 °C. Factory setting

10 °C.

A10

Longest permitted defrosting time. The value is adjustable

between 5 and 12 minutes. Factory setting 7 minutes.

A11

NOTE

In the event of any defrosting problems, the

value in channel A11 can be increased to relieve

the problem.

Manual activation of defrosting procedure. Change the

value 0 to 1 and confirm using the Enter button.

A12

Restore factory default settings. Change the value 0 to 1

and confirm using the Enter button.

A13

F2015

22

For the Installer

Control

Содержание F2015

Страница 1: ...INSTALLATION AND MAINTENANCE INSTRUCTIONS MOS GB 1008 3 F2015 031239 F2015 LEK ...

Страница 2: ......

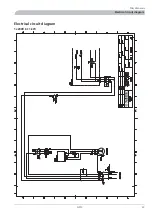

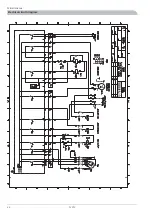

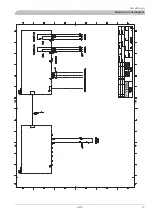

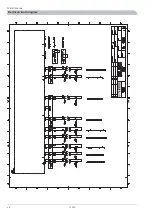

Страница 27: ...Electrical circuit diagram 1x230V 6 11 kW 25 F2015 Miscellaneous Electrical circuit diagram ...

Страница 28: ...F2015 26 Miscellaneous Electrical circuit diagram ...

Страница 29: ...27 F2015 Miscellaneous Electrical circuit diagram ...

Страница 30: ...F2015 28 Miscellaneous Electrical circuit diagram ...

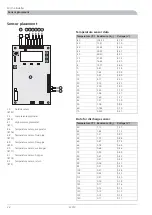

Страница 31: ...Technical specifications Component positions LEK LEK 29 F2015 Miscellaneous Technical specifications ...

Страница 40: ...F2015 38 ...

Страница 41: ...39 F2015 ...

Страница 42: ...F2015 40 ...

Страница 43: ......