- 85 -

L5034G4 AGCO

www.NewLeader.com

(800) 363-1771

306375-AA-E

Spread Pattern

DETERMINING DRIVING CENTERS

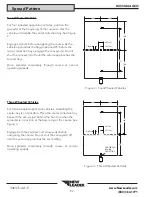

Once an acceptable pattern is obtained, as shown in Figure 5, driving centers can be determined� To

determine optimum driving centers (effective swath width), determine the average amount of material

in the center of the pattern. Figure 8 shows an example data sheet recorded from the profile shown in

Figure 9� Based on the example, the average amount of material in the center of the pattern is 3�0, as

indicated with the red dotted line�

Next, locate the points on both the left and right side of the pattern where the amount of material is

half the average amount at the center of the pattern� In the example shown in Figure 8, these points are

located 45’ to the left of center, and 45’ to the right of center� The distance between these two points

(90’) represents the driving centers to use�

NOTE: Once the effective swath width has been established, a change in the controller may be required�

313964-A

Temperature:

°F

lbs/acre

Spinner Speed:

RPM

Controller Vehicle Speed:

MPH

Controller Swath Width:

10’

15’

20’

25’

30’

35’

40’

45’

50’

55’

-0-

10’

15’

20’

25’

30’

35’

40’

45’

50’

55’

1

2

3

4

5

6

7

1

2

3

4

5

6

7

60’

60’

3.5

3.0

3.0

3.03.0

3.0

3.0

2.5

2.5

2.5 2.5 2.5 1.50.5

2.5 2.5

2.0

1.5

0.5

ACCEPTABLE PATTERN

Average amount of

material in the center

of the pattern = 3

EFFECTIVE SWATH WIDTH: 45’+ 45’ = 90’

45’

45’

Points where material is half of the center of the pattern = 1.5

Figure 8 - Effective Swath Width

Figure 9

80’

80’

90’

90’

100’

100’

Содержание L5034G4 AGCO

Страница 5: ...5 L5034G4 AGCO www NewLeader com 800 363 1771 306375 AA E This page is intentionally left blank Notes...

Страница 6: ...Insert Current New Leader Warranty Warranty...

Страница 37: ...37 L5034G4 AGCO www NewLeader com 800 363 1771 306375 AA E Troubleshooting Hydraulic Schematic...

Страница 76: ...76 Notes This Page Intentionally Left Blank...