4

|

ni.com

|

Getting Started with NI 9501 Modules and NI SoftMotion

NI SoftMotion Module Overview

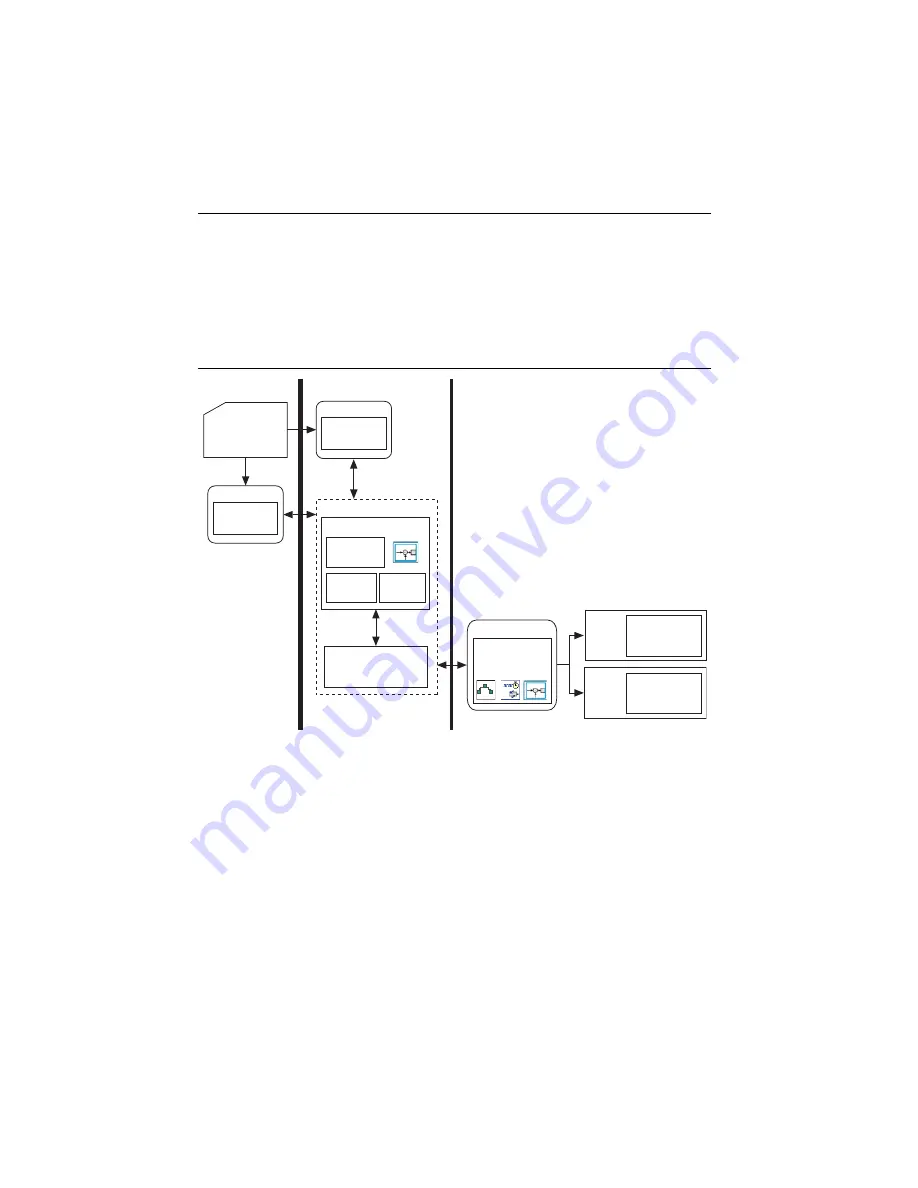

NI SoftMotion Module UDV axes allow you to implement an interface for communication

between the NI SoftMotion Engine and the LabVIEW FPGA Module. This is achieved using

user-defined variables that you add to the project, making it easier to use C Series modules in

FPGA mode with the NI SoftMotion Module.

The following figure shows the NI SoftMotion architecture when you use the NI SoftMotion

Module with UDV axes and the LabVIEW FPGA Module.

Figure 2.

NI SoftMotion Module with UDV Axes

You use the LabVIEW Project to configure your axis settings and test your configuration. When

your hardware configuration is complete, you use NI SoftMotion APIs to create move profiles.

Communication to the LabVIEW FPGA Module is handled through user-defined variables. You

use the NI SoftMotion Drive Interface VIs to implement an interface for communication

between the NI SoftMotion Engine and the LabVIEW FPGA Module. When you use the Drive

Interface VIs with UDV axes you communicate using a predefined set of UDVs. Refer to

Adding

User-Defined Variables for Use With a UDV Axis

in the

NI SoftMotion Module Help,

available

by selecting

Help»LabVIEW Help

for information about the predefined UDVs. Refer to the

Using NI 9501 with NI SoftMotion

section for more information about the NI SoftMotion Drive

Interface VIs.

Axi

s

Interf

a

ce

Tr

a

jectory

Gener

a

tor

Su

pervi

s

ory

Control

Ho

s

t HMI

a

nd

Axi

s

S

etting

s

:

L

a

bVIEW Project

Non Real-Time

LabVIEW Real-Time Module

NI SoftMotion

U

s

er VI

NI

S

oftMotion

API

s

LabVIEW FPGA with

NI Scan En

g

ine Supported Platform

C

S

erie

s

Mod

u

le(

s

)

cRIO

Ch

ass

i

s

Motor Control,

Drive Interf

a

ce,

a

nd

S

ync VI

s

cRIO

Ch

ass

i

s

NI 950x

C

S

erie

s

Mod

u

le(

s

)

U

s

er-Defined V

a

ri

a

ble

Comm

u

nic

a

tion

Mod

u

le

U

s

er VI

NI

S

oftMotion

API

s

U

s

er VI

NI

S

oftMotion Engine