MAINTENANCE

Seasonal maintenance

WEEKLY - DESCALE

Push and pull the de-scaling lever in and out as well as turning

slightly at the same time completely two or three times. Push in for

normal burner operations or before relighting.

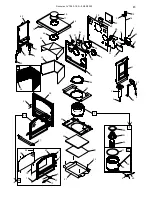

EVERY 3 TO 4 MONTHS - CLEAN BURNER

Remove all three catalyser components (C, D, E, figure 13). Remove

any carbon residue and remaining oil from the burner using a slightly

damp cloth. Buff dry before reinstalling.

EVERY 3 TO 4 MONTHS - CHIMNEY INSPECTION

The chimney and the chimney connector must be inspected at least

once every 3 months during the heating season to ascertain whether

there has been a buildup of soot in the system. If a soot buildup has

occurred, it should be removed to reduce the risk of chimney fires.

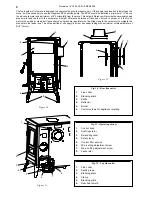

ONCE OR TWICE A YEAR - FLUE BAFFLES INSPECTION

- Remove the flue baffles (figure 18 and 19). If a soot buildup has

occurred on the flue baffles and the combustion chamber, it should

be removed.

YEARLY - CHIMNEY MAINTENANCE

The chimney is to be swept at least once a year. It is also

recommended that prior to every heating season the entire system

be professionally inspected, cleaned and repaired where necessary.

YEARLY - CLEAN CARBURETOR FILTER

1

. Set the control knob to “0".

2.

Turn off oil supply at the valve or the tank valve.

3.

Raise the safety lever (D).

4.

Place a container under the carburetor to contain any spillage. Remove the filter plug held on with two screws.

5.

Pull out the filter (E) and clean in oil

using a soft brush. Never use a wire brush.

6.

Replace filter and plug.

Clean all enamelled stove panels and the outside of the glass using a slightly dampened cloth.

NEVER CLEAN WHEN

THE STOVE IS HOT.

DOOR GASKET REPLACEMENT

Check the door gasket periodically to ensure the seal is functioning properly and the door fits tight. Replace the gasket if

necessary.

Removing the flue baffles

Document n° 1092-1 EN ~ 04/02/2002

11

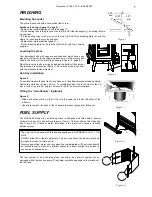

Figure 17 - Float regulator (carburetor)

B

C

D

F

H

G

E

A

A

: control knob

B :

thermostat control

C :

oil level regulator

D :

safety lever

E :

filter

F :

main float

G :

safety float

H :

filter cavity

Figure 18

Figure 19

Содержание OS10-3

Страница 15: ...Document n 1092 1 EN 04 02 2002 15 Notes...