SCHEDULE TYPE:

PROJECT:

ENGINEER:

CONTRACTOR:

Nailor Industries Inc. reserves the right to change any information concerning product or pricing without notice.

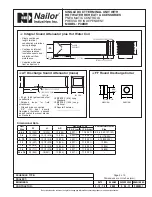

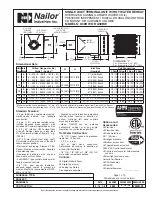

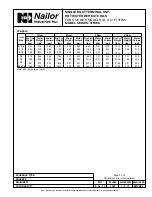

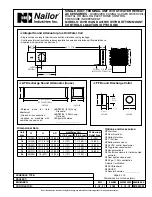

Standard Features:

• Bottom mount controls location with

vertical drive shaft (option code OB).

• 22 ga. (0.86) zinc coated steel casing,

mechanically sealed, low leakage

construction.

• 16 ga. (1.61) corrosion-resistant steel

inclined opposed blade damper with

extruded PVC seals (single blade on size

4, 5, 6). 45

°

rotation, CW to close.Tight

close-off. Damper leakage is less than

2% of the terminal rated airflow at 3" w.g.

(750 Pa).

•1/2" (13) dia. plated steel drive shaft.

An indicator mark on the end of the shaft

shows damper position.

• Multi-point averaging Diamond Flow

Sensor. Aluminum construction. Supplied

with balancing tees.

• Rectangular discharge with slip and

drive cleat duct connection.

• Full NEMA type-1 controls enclosure for

factory mounted controls.

•

3/4" (19), dual density insulation,

exposed edges coated to prevent air

erosion. Meets the requirements of NFPA

90A and UL 181.

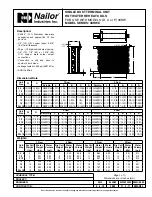

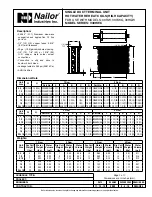

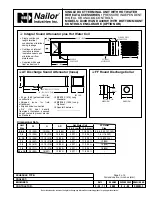

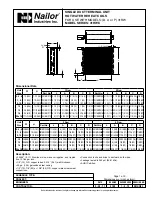

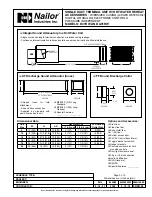

Hot Water Coil Section:

• 1/2" (13) Copper tubes and aluminum

ripple fins, 10 per inch.

• 1, 2, 3 or 4 row.

•

Left or right hand connection.

Determined by looking in direction of

airflow (RH illustrated).

• 1/2" (13), 7/8" (22) or 1 3/8" (35) O.D.

male solder sweat connections.

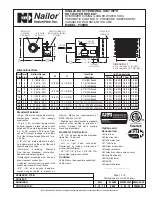

Controls:

q

Digital (by others).

q

Analog (by Nailor).

See separate submittal.

Options and Accessories:

q

Steri-liner.

q

Fiber-free liner.

q

Solid metal liner.

q

1" (25) liner.

q

Bottom access door.

q

24 VAC Control transformer.

q

Toggle disconnect switch.

q

Hanger brackets.

q

Controls enclosure for field mounted

controls.

q

Dust tight enclosure seal.

q

Special Features:

___________________________ .

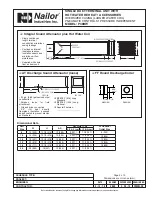

DATE

B SERIES

SUPERSEDES DRAWING NO.

3 - 15 - 18

3000

2 - 19 - 18 D30RW-OC-2

Page 1 of 2.

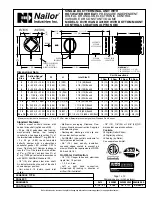

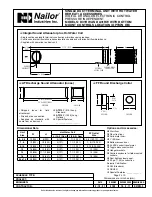

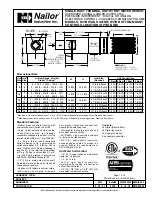

Dimensions are in inches (mm).

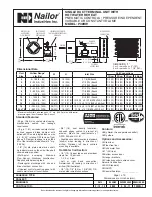

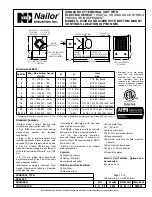

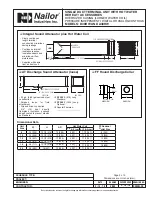

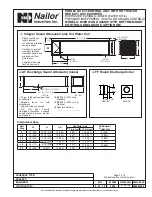

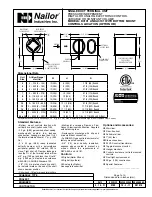

SINGLE DUCT TERMINAL UNIT W/HOT WATER REHEAT

OVERSIZED CASING (LARGER WATER COIL)

DIGITAL OR ANALOG CONTROLS • CONSTANT OR

VARIABLE VOLUME • PRESSURE INDEPENDENT

MODELS: D30RW AND A30RW WITH BOTTOM MOUNT

CONTROLS LOCATION (OPTION OB)

OPTIONAL

ACCESS DOOR

SLIP AND DRIVE

CONNECTION

14" (356)

5 1/2"

(140)

6"

(152)

1/2"

(13)

INLET: ROUND

OR FLAT OVAL

MULTI-POINT

AVERAGING

FLOW SENSOR

11" (279)

22 1/2" (572)

W

H

DAMPER

DRIVESHAFT

L

W

H

DIMENSION "L"

1 OR 2 ROW COILS, L = 5" (127)

3 OR 4 ROW COILS, L = 7" 1/2 (191)

CONTROLS ENCLOSURE

FOR FACTORY

MOUNTED CONTROLS

AIRFLOW

*

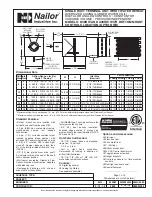

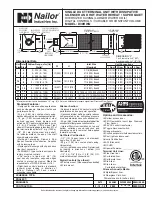

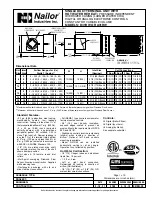

Maximum airflow limit is based upon 1.5" w.g. (373 Pa) max. differential pressure signal from Diamond Flow Sensor.

**

Maximum airflow limit is based upon 1.0" w.g. (249 Pa) max. differential pressure signal from Diamond Flow Sensor.

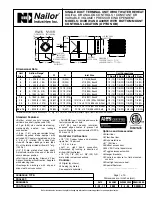

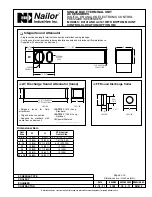

Unit

Size

Inlet

Size

Airflow Range, cfm (I/s)

Digital* / Analog**

W

H

Inlet Size

(Nominal)

Coil Connections

1 Row 2 Row 3 Row 4 Row

4

0 – 225 (0 – 106)/0 – 180 (0 – 85)

3 7/8 (98) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

8

5

0 – 400 (0 – 189)/0 – 325 (0 – 153) 12 (305) 12 1/2 (318)

4 7/8 (124) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

6

0 – 550 (0 – 260)/0 – 450 (0 – 212)

5 7/8 (149) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

10

7

0 – 800 (0 – 378)/0 – 650 (0 – 307)

14 (356) 12 1/2 (318)

6 7/8 (175) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

8

0 – 1100 (0 – 519)/0 – 900 (0 – 425)

7 7/8 (200) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

12

9

0 – 1400 (0 – 661)/0 – 1150 (0 – 543)

18 (457) 12 1/2 (318)

8 7/8 (225) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

10

0 – 1840 (0 – 868)/0 – 1500 (0 – 708)

9 7/8 (251) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

14

12

0 – 2500 (0 – 1180)/0 – 2050 (0 – 967) 24 (610) 12 1/2 (318) 12 15/16 x 9 13/16 (329 x 249) Oval 1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

16

14

0 – 3125 (0 – 1475)/0 – 2550 (0 – 1203) 28 (711) 12 1/2 (318) 16 1/16 x 9 13/16 (408 x 249) Oval 7/8 (22) 7/8 (22) 7/8 (22) 7/8 (22)

24

16

0 – 3725 (0 – 1758)/0 – 3040 (0 – 1435) 38 (965)

18 (457)

19 3/16 x 9 13/16 (487 x 249) Oval 7/8 (22) 7/8 (22) 1 3/8 (35) 1 3/8 (35)

Dimensional Data